Technology for enhancing low temperature flue gas while performing desulfurization and denitrification by using combined additive

A low-temperature flue gas, desulfurization and denitrification technology, applied in air quality improvement, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of low denitration rate, unable to meet NOx emission standards, difficult to effectively absorb, etc., to improve the denitration rate. , Improve the purity and promote the effect of denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

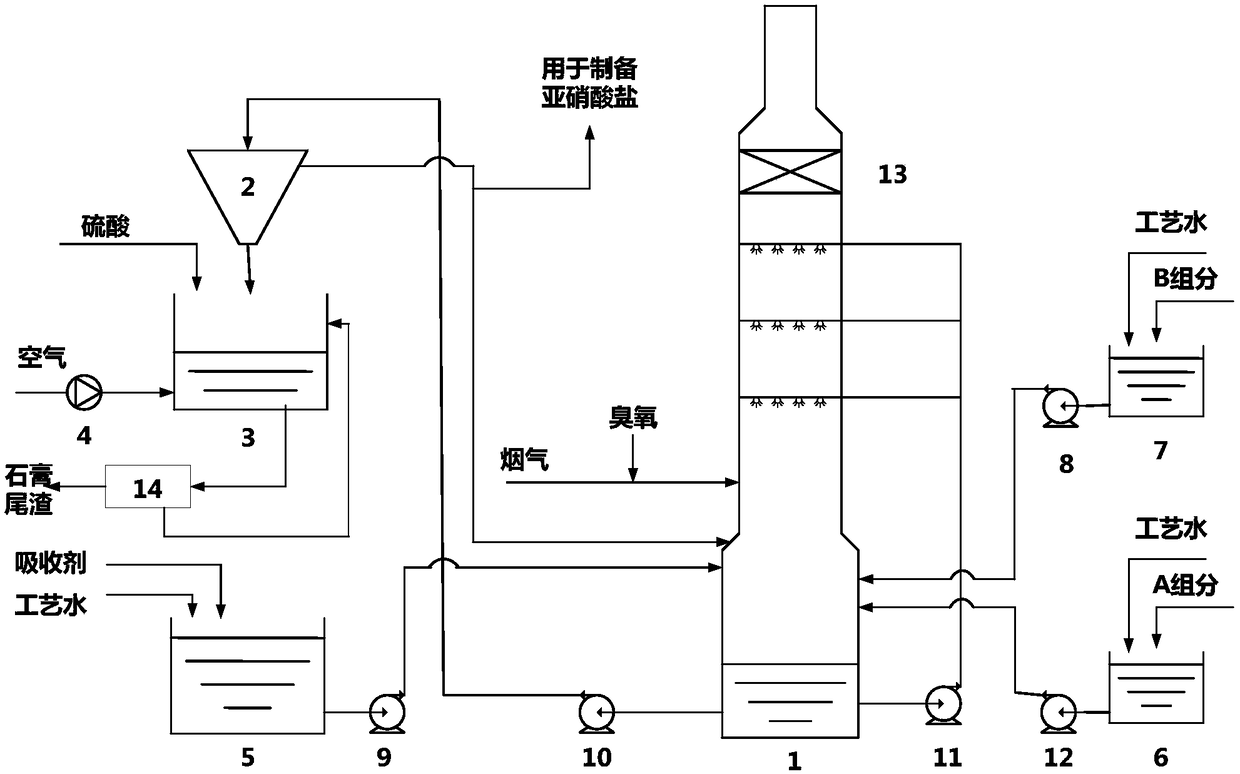

[0034] SO in coke oven flue gas 2 Concentration 500mg / Nm 3 , NO x Concentration 400mg / Nm 3 , the temperature is 170°C. Adopt technology described in the present invention to process, and concrete method is:

[0035] (1) The flue gas is first mixed with a certain amount of ozone for oxidation, and the molar ratio of ozone to NOx in the flue gas is 1.1.

[0036] (2) The oxidized flue gas enters the absorption tower 1, contacts with the absorption slurry containing calcium-based absorbent and combined additives, and removes SO therein 2 and NOx. The pH of the absorption slurry was maintained between 5.5-6. Among them, the calcium-based absorbent is limestone, the component A in the combined auxiliary agent is sodium thiosulfate, and the component B is ammonia water. Sodium thiosulfate is mixed and dissolved with process water in component A dissolving tank 6 to obtain a solution, and ammonia water is directly added to component B dissolving tank 7 for subsequent use. Sodi...

Embodiment 2

[0041] SO in a sinter flue gas 2 Concentration 2000mg / Nm 3 , NO x Concentration 300mg / Nm 3 , the temperature is 150°C. Adopt technology described in the present invention to process, and concrete method is:

[0042] (1) The flue gas is first mixed with a certain amount of ozone for oxidation, and the molar ratio of ozone to NOx in the flue gas is 1.0.

[0043] (2) The oxidized flue gas enters the absorption tower 1, contacts with the absorption slurry containing calcium-based absorbent and combined additives, and removes SO therein 2 and NOx. The pH of the absorption slurry was maintained between 6.5-7. Among them, the calcium-based absorbent is quicklime, the A component in the combined auxiliary agent is potassium thiosulfate, and the B component is ammonium sulfate. Potassium thiosulfate and ammonium sulfate are mixed and dissolved with process water in component A dissolving tank 6 and component B dissolving tank 8 respectively to prepare solutions for subsequent us...

Embodiment 3

[0048] SO in the flue gas of a coal-fired boiler 2 Concentration 3000mg / Nm 3 , NO x Concentration 250mg / Nm 3 , the temperature is 130°C. Adopt technology described in the present invention to process, and concrete method is:

[0049] (1) The flue gas is first mixed with a certain amount of ozone for oxidation, and the molar ratio of ozone to NOx in the flue gas is 0.9.

[0050] (2) The oxidized flue gas enters the absorption tower 1, contacts with the absorption slurry containing calcium-based absorbent and combined additives, and removes SO therein 2 and NOx. The pH of the absorption slurry was maintained at 7-7.5. Among them, the calcium-based absorbent is calcium carbide slag, the A component in the combined additive is calcium thiosulfate, and the B component is ammonium sulfite. Calcium thiosulfate and ammonium sulfite are respectively mixed and dissolved with process water in component A dissolving tank 6 and component B dissolving tank 8 to prepare solutions for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com