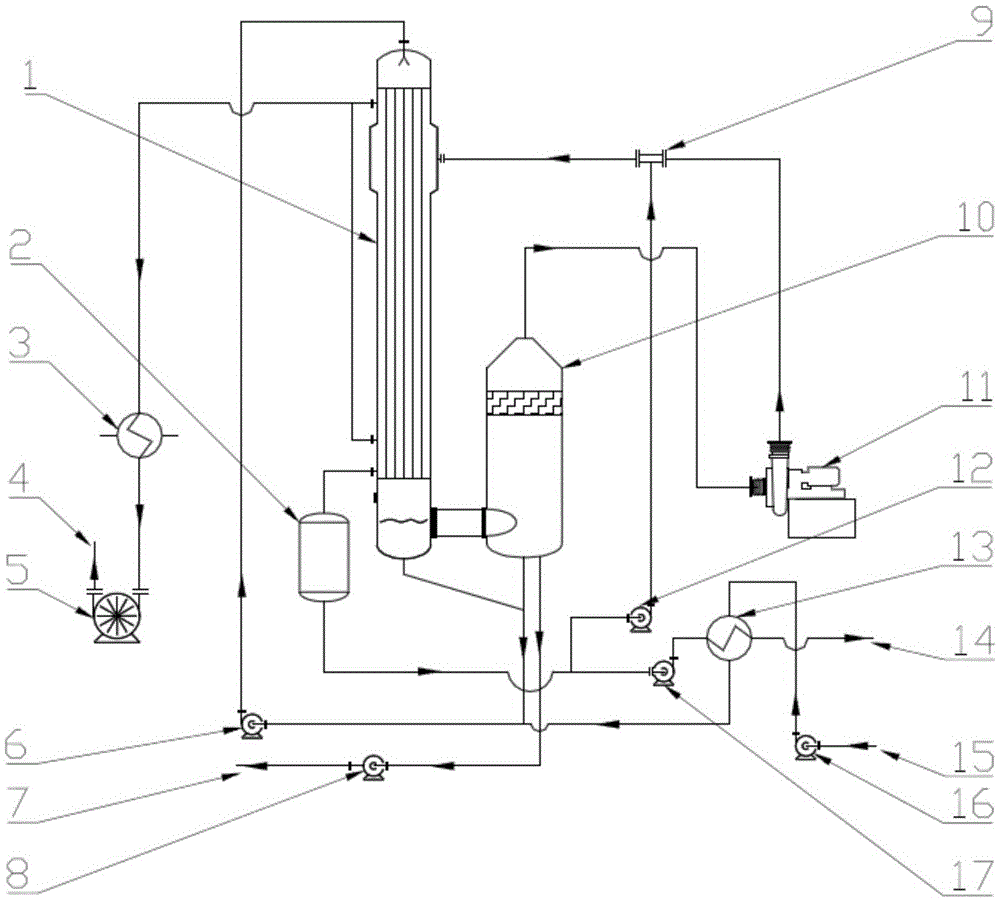

Alumina mother liquor MVR circulation evaporation device and process

An evaporation device and alumina technology, applied in the direction of alumina/hydroxide, etc., can solve the problems of large carbon emissions, high energy consumption, and long process flow, and achieve the goals of increasing production capacity, improving quality, and reducing evaporation energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] There are two sets of six-effect three-flash mother liquor evaporators in an alumina factory, and the actual operating distilled water volume is about 360 tons / hour. The production has repeatedly increased the steam pressure, and the forced effect is used to meet the evaporation, resulting in a substantial increase in overall energy consumption. It is still difficult to meet the production with a steam-water ratio of 0.28 or more. For this reason, it is solved by adding a set of MVR mother liquor concentration equipment. It solved the difficulties it faced and achieved good economic and social benefits.

[0038] A group of evaporated seed separation mother liquor 350m3 / h is pumped from the feed port 15 to the plate preheater 13 through the feed pump 16, preheated by evaporating condensed water, recovering the heat of the condensed water, and then sent to the falling film through the circulating pump 6 Evaporator 1 top. The mother liquor falls from the top of the fallin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com