Pre-treatment method for promoting high concentration starch to liquefy

A starch liquefaction and pretreatment technology, which is applied in the field of starch sugar production, can solve the problems of difficult stirring and uniform mixing, high viscosity of starch paste, etc., and achieve the effects of reducing viscosity, reducing evaporation energy consumption, and improving industrial water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

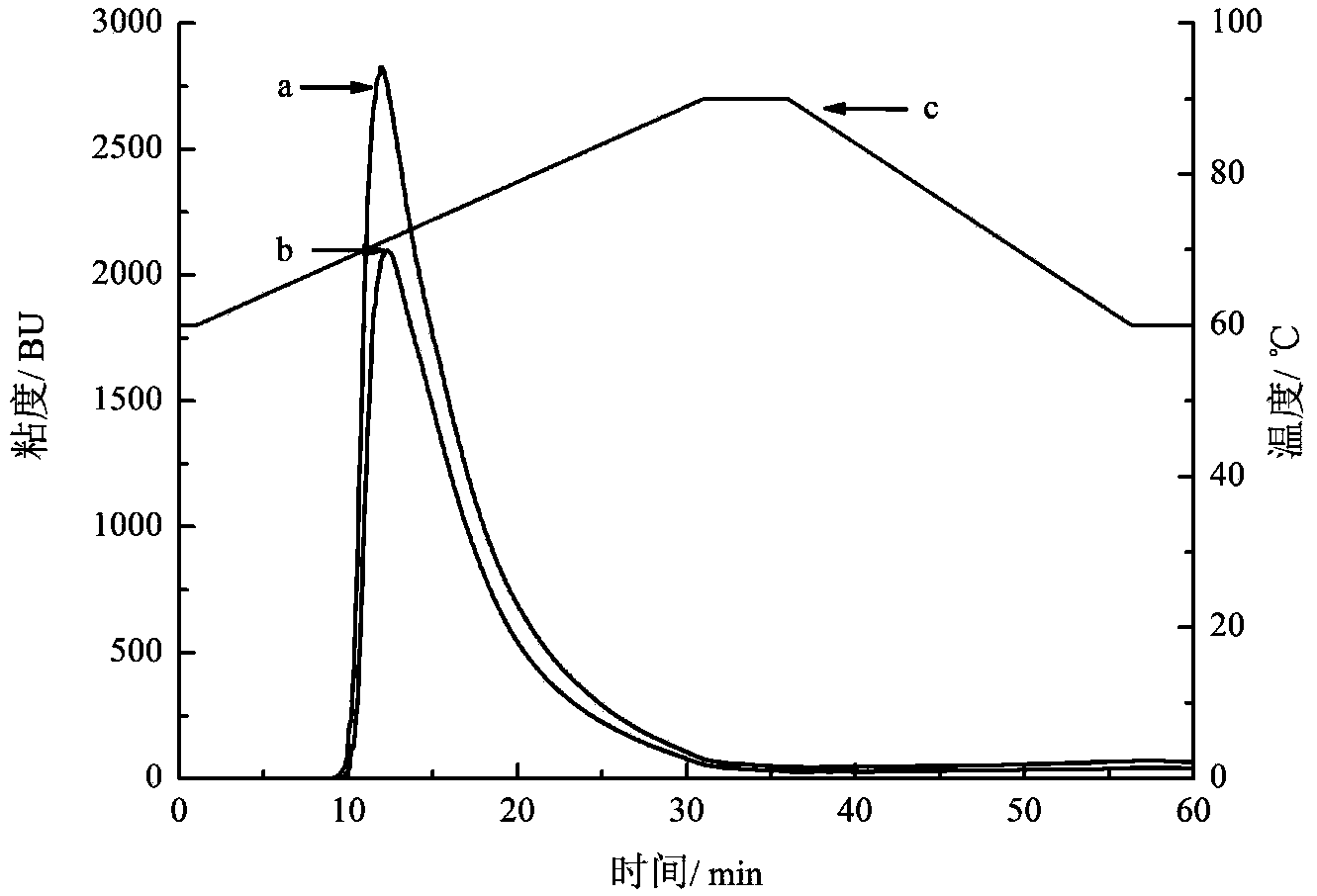

[0026] Prepare starch milk with a mass concentration of 45% (w / w, on a dry basis of starch) at 60°C, adjust the pH value to 6.0 with 0.1M hydrochloric acid, add 0.25U / g starch (on a dry basis), and warm α- Insulate the amylase for 15 minutes, add deionized water to dilute to 20%, pour the treated starch milk into the storage tank of the Brabender viscometer, set the program: from 60°C to 90°C at a heating rate of 1°C / min Maintain for 5 minutes, then lower the temperature to 60°C at a cooling rate of 1.5°C / min, and measure the viscosity during the liquefaction process. The medium-temperature α-amylase was added and the incubation time was 0 min as the blank control group. The result is as figure 1 As shown, the curve a in the figure is the incubation time of 0 min after adding the medium-temperature α-amylase, the curve b is the incubation time of 15 minutes after adding the medium-temperature α-amylase, and the curve c is the temperature line. Adding 0.25U / g mesophilic α-amy...

Embodiment 2

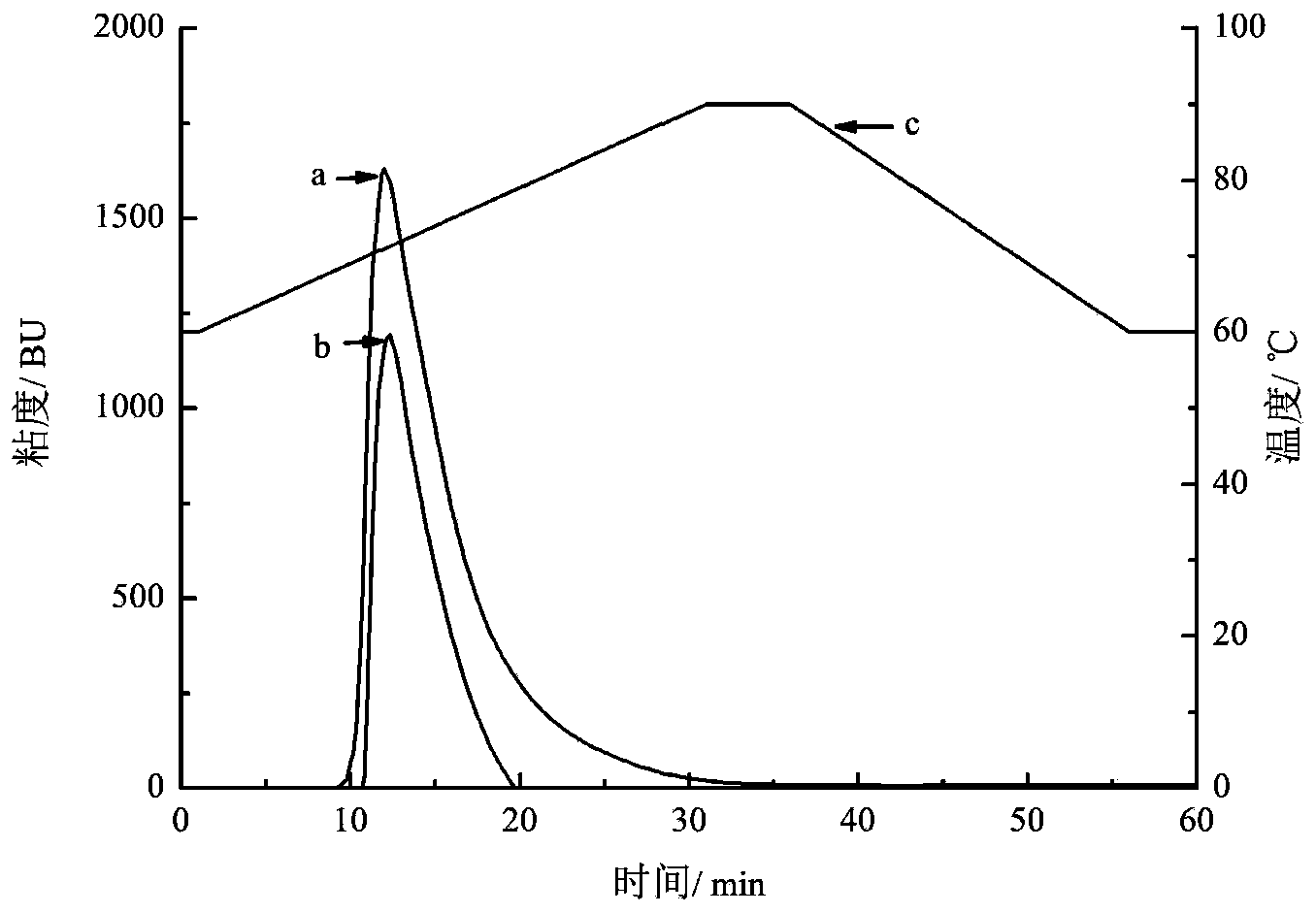

[0028] Prepare starch milk with a mass concentration of 45% (w / w, based on starch dry basis) at 60°C, adjust the pH value to 6.0 with 0.1M hydrochloric acid, add 0.5U / g starch (based on dry basis) and warm α- Amylase (Genencor (China) Bioengineering Co., Ltd.) was incubated for 15 minutes, diluted to 20% by adding deionized water, and the treated starch milk was poured into the storage tank of the Brabender viscometer. The setting program: from 60°C Raise the temperature to 90°C at a heating rate of 1°C / min and maintain it for 5 minutes, then lower the temperature to 60°C at a cooling rate of 1.5°C / min, and measure the viscosity during the liquefaction process. With the addition of medium temperature α-amylase and the incubation time of 0 min as the blank control group, the results are as follows: figure 2 As shown, the curve a in the figure is the incubation time of 0 min after adding the medium-temperature α-amylase, the curve b is the incubation time of 15 minutes after ad...

Embodiment 3

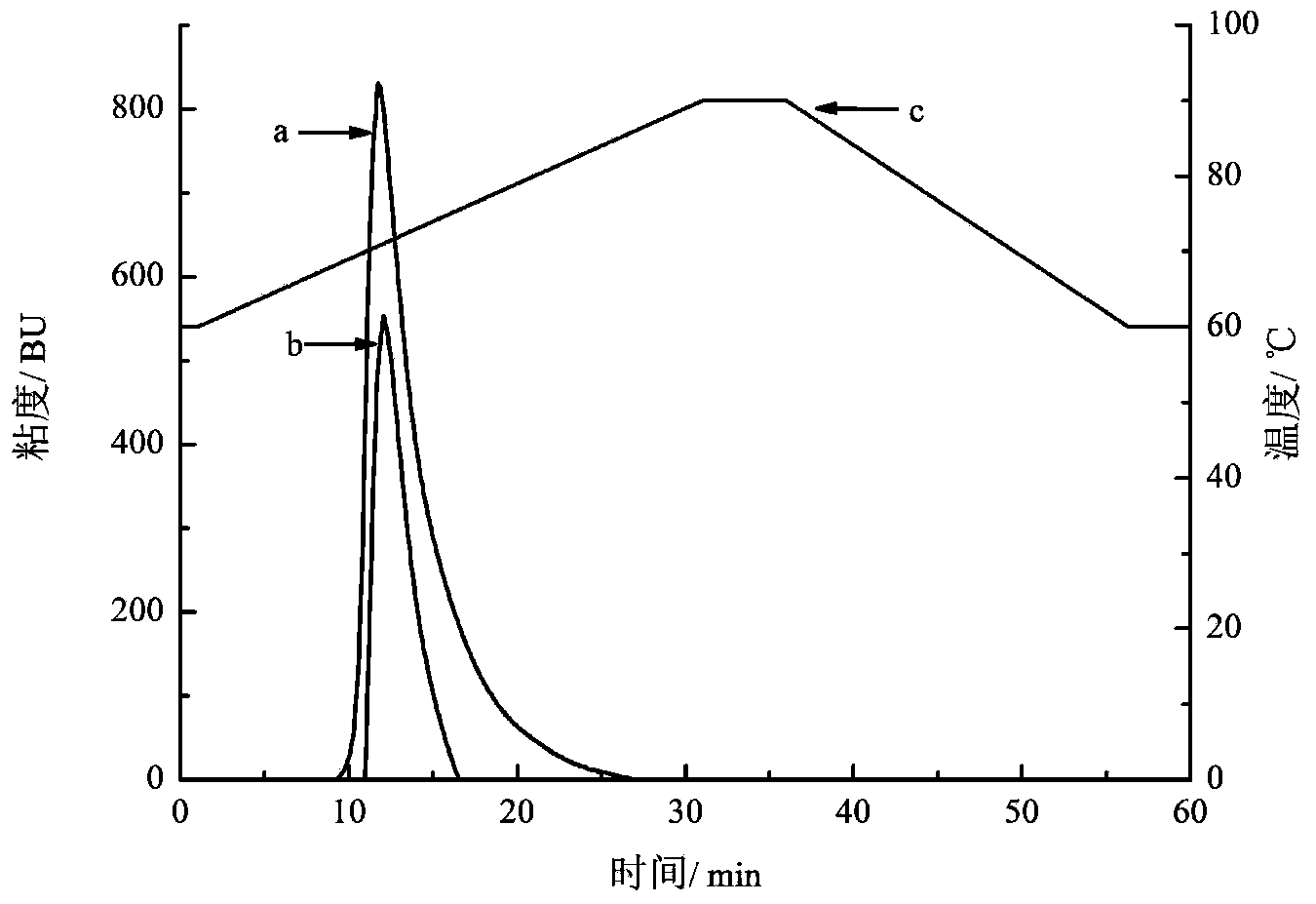

[0030] Prepare starch milk with a mass concentration of 50% (w / w, based on starch dry basis) at 60°C, adjust the pH value to 6.0 with 0.1M hydrochloric acid, add 1U / g starch (based on dry basis) and warm α-starch Enzyme heat preservation treatment for 30 minutes, add deionized water to dilute to 20%, and pour the treated starch milk into the storage tank of the Brabender viscometer, set the program: from 60°C to 90°C at a heating rate of 1°C / min 5min, then lower the temperature to 60°C at a rate of 1.5°C / min, and measure the viscosity during the liquefaction process. The medium-temperature α-amylase was added and the incubation time was 0 min as the blank control group. The result is as image 3 As shown, the curve a in the figure is the addition of medium-temperature α-amylase for 0 minutes of incubation, the curve b is the addition of medium-temperature α-amylase for incubation of 30 minutes, and the curve of c is the temperature line. The addition of 1U / g mesophilic α-amy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com