Ethylamine production system and technology for conducting membrane separation-hydrolysis treatment on wastewater

A technology for treating wastewater and production systems, which is applied in water/sewage treatment, natural water treatment, heating water/sewage treatment, etc., and can solve problems such as adverse environmental impact and treatment difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

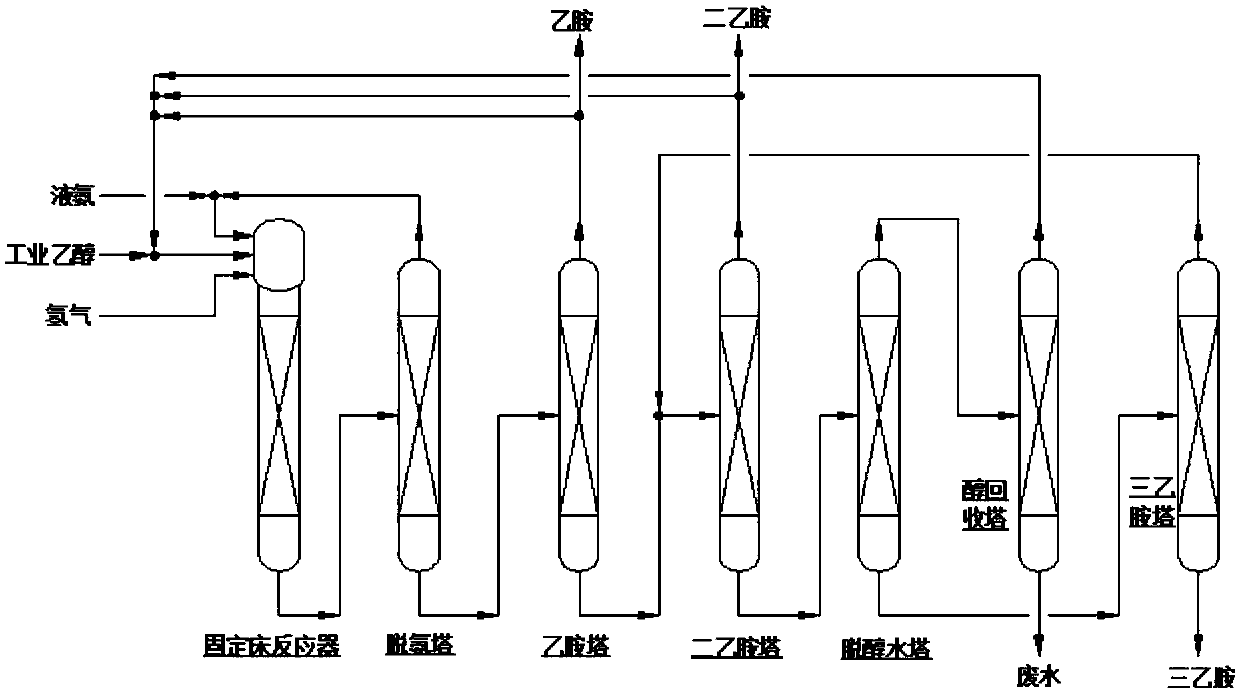

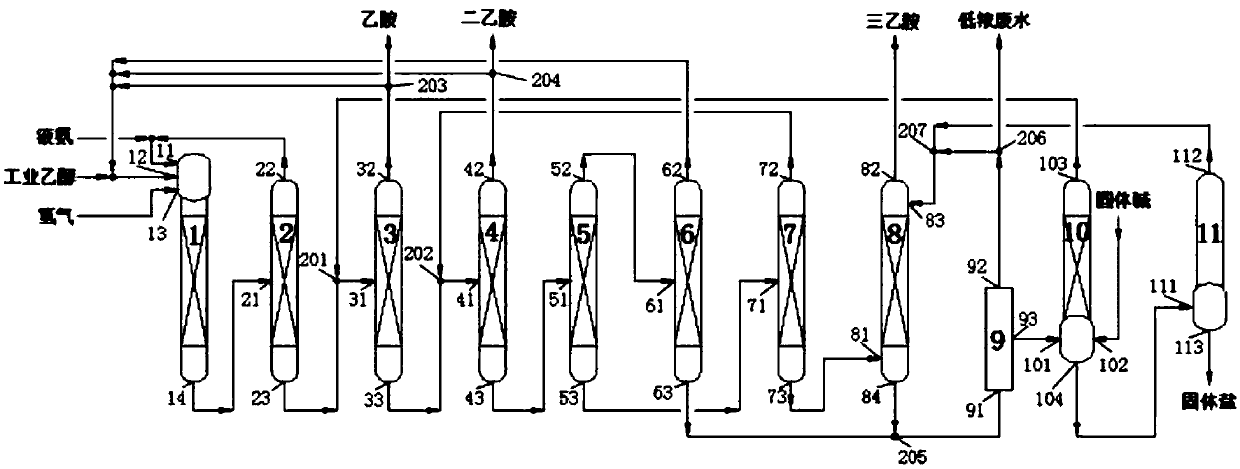

[0073] Example 1, a kind of ethylamine production system of membrane separation-hydrolysis treatment waste water, consists of fixed bed reactor 1, deammonization tower 2, ethylamine tower 3, diethylamine tower 4, dealcoholization water tower 5, alcohol recovery tower 6, A triethylamine tower 7, an extraction tower 8, a reverse osmosis membrane separator 9, a hydrolysis rectification tower 10 and an evaporator 11 are formed;

[0074] The upper part of the fixed bed reactor 1 is a vaporization chamber, and the lower part is a fixed bed reaction section, and the vaporization chamber is provided with an ammonia inlet 11, an ethanol inlet 12 and a hydrogen inlet 13;

[0075] Deamination tower 2, ethylamine tower 3, diethylamine tower 4, dealcoholization water tower 5, alcohol recovery tower 6, and triethylamine tower 7 are rectification towers, all of which are respectively provided with feed ports, The top is provided with an overhead distillate outlet and the bottom plate is prov...

Embodiment 1

[0100] Embodiment 1, utilize the production device as described in example 1 to carry out the ethylamine production process for membrane separation-hydrolysis treatment waste water, comprise the steps:

[0101] The liquid ammonia transported from the liquid ammonia inlet pipe and the ammonia gas from the top of the deamination tower 2 all enter the vaporization chamber of the fixed-bed reactor 1 through the ammonia inlet 11, and the industrial ethanol transported from the industrial ethanol inlet pipe, The ethylamine from the top of the ethylamine tower 3, the diethylamine from the top of the diethylamine tower 4 and the aqueous ethanol solution from the top of the alcohol recovery tower 6 all enter the vaporization of the fixed-bed reactor 1 through the ethanol inlet 12 room, all the above-mentioned materials enter the vaporization chamber to form raw materials, and the molar ratio of each substance in the raw materials is about ammonia:ethanol:ethylamine:diethylamine=50:135:1...

Embodiment 2

[0113] Embodiment 2, with respect to embodiment 1, change following parameter:

[0114] The mol ratio of each material in the raw material is ammonia: ethanol: ethylamine: diethylamine=43:90:10:10; Hydrogen regulates fixed-bed reactor 1 internal pressure to 0.8MPa, and fixed-bed reaction section is provided with activated catalyst ( The active component in this catalyst is cobalt and nickel, and the content of active component cobalt is 8%, and the content of cobalt is 10%, and carrier is 4A molecular sieve, and the activation treatment of hydrogen reduction before use); the reaction in fixed-bed reactor 1 The temperature is controlled at 180°C; the volumetric space velocity is 0.20h -1 ;

[0115] In the deamination tower 2, the temperature of the tower kettle is set at 50°C, and the tower top pressure is 0.8MPa; in the ethylamine tower 3, the temperature of the tower kettle is set at 55°C, and the tower top pressure is normal pressure; Tower still temperature is 65 ℃, tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com