Potassium chloride production process for decomposing carnallite with cleaning solution

A production process and cleaning solution technology, which is applied in the purification of alkali metal chlorides and alkali metal halides, can solve the problems of incomplete decomposition of carnallite, unfavorable decomposition of carnallite, and increased loss of potassium chloride. Achieve the effect of benefiting production operation, reducing water content and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

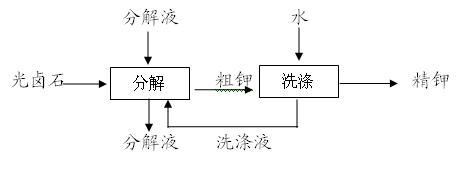

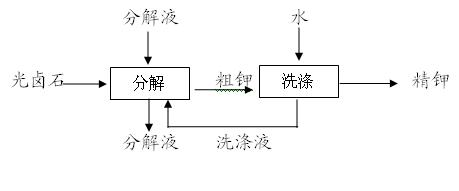

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] The following steps are further explained in detail

[0019] a. Carnallite is dispersed into the crystallizer by the washing liquid. During the production process, the crude potassium is washed with water, and then dehydrated to form the finished product. The released water is the washing liquid;

[0020] b. In the crystallizer, add water to decompose, and the concentration is controlled at 31.5-31.7 〇 Be',

[0021] c. The above-mentioned decomposition complete liquid is dehydrated and separated to obtain crude potassium chloride and decomposition liquid,

[0022] d. Then the crude potassium chloride obtained in step c is washed with water to obtain a concentration controlled at 27-27.2 〇 Potassium chloride solution of Be',

[0023] E. get potassium chloride product and washing liquid after potassium chloride solution dehydration,

[0024] f. Decompose carn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com