Method for raising temperature of vaporizing raw liquor

A technology of evaporating stock solution and evaporation station, which is applied in the field of alumina plant, which can solve the problems of increased energy consumption of evaporating stock solution, heat loss, vibration of transportation pipelines, etc., and achieves the effects of reducing evaporation energy consumption, eliminating violent vibration, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

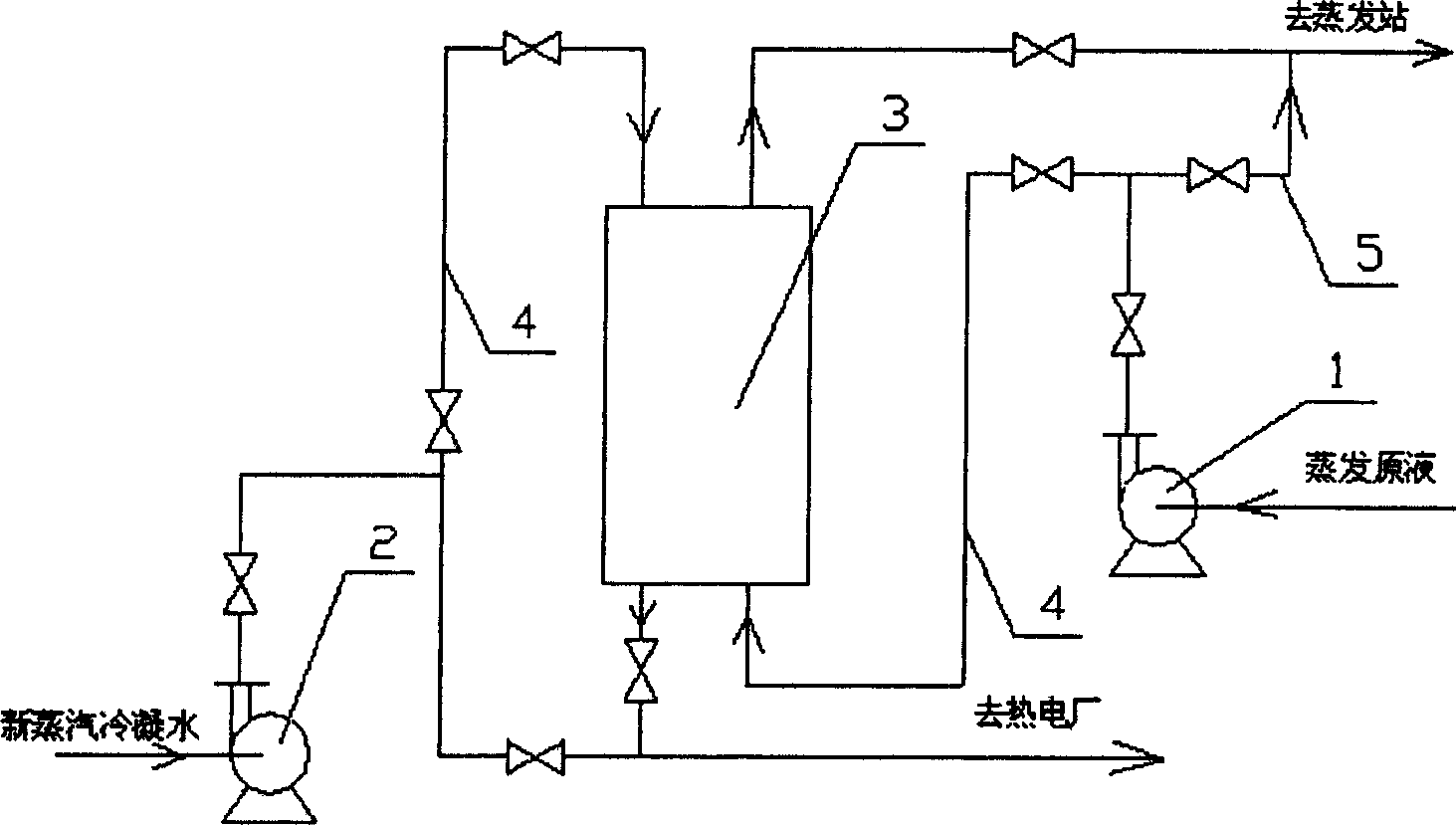

[0008] Embodiments of the present invention: as attached figure 1 As shown, when increasing the temperature of the evaporating stock solution, a part of the evaporating stock solution from the stock solution pump 1 directly enters the evaporation station through the bypass pipe 5 arranged behind the stock solution pump 1 for evaporation, and the other part of the evaporated stock solution enters along the pipeline 4 into the In the plate heat exchanger 3, heat exchange is performed with the new steam condensed water that enters the plate heat exchanger 3 from the leaching condensate pump 2, and the evaporated raw liquid heated up after the heat exchange is combined with the evaporated raw liquid in the bypass pipe 5 Enter the evaporation station for evaporation; while the new steam condensate from the dissolution condensate pump 2 enters the plate heat exchanger 3 along the pipeline 4 to exchange heat with the evaporation stock solution, and the cooled steam condensate enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com