Treatment method of high-concentration salt-containing waste sulfuric acid

A high-concentration salt-containing, treatment method technology, applied in the field of high-concentration salt-containing waste sulfuric acid, can solve the problems that landfills do not want to accept salt mud for landfill, salt mud cannot be disposed of, and are piled in warehouses, etc., to achieve Achieve resource utilization, save evaporation energy consumption, and reduce the effect of wastewater salinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

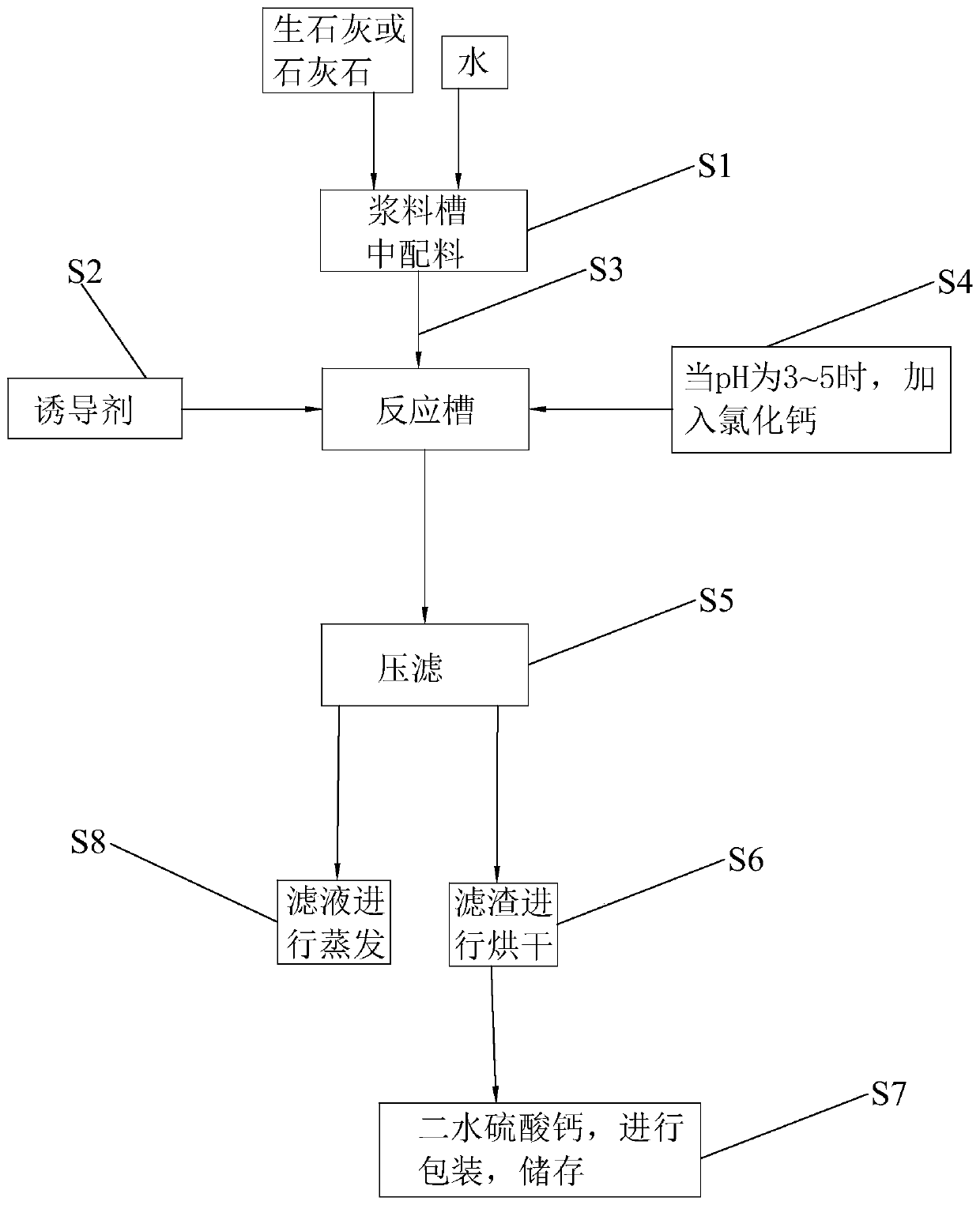

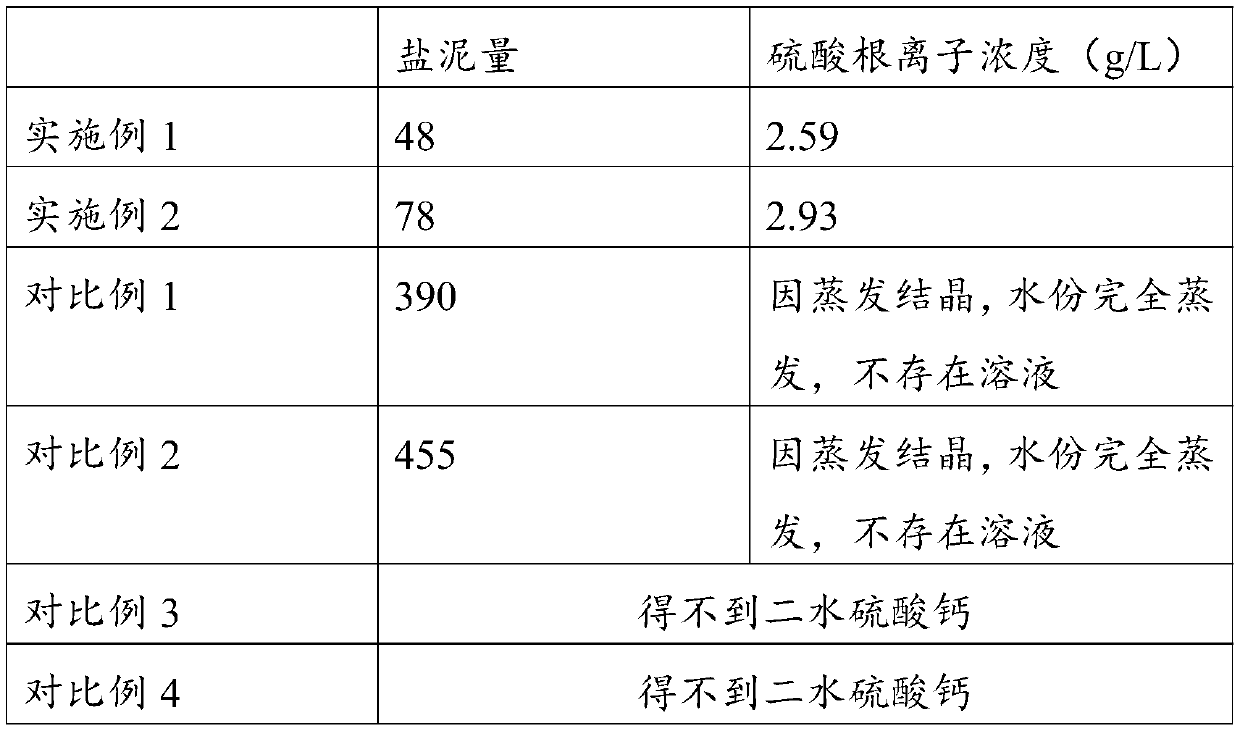

[0034] The processing method of high-concentration saline waste sulfuric acid in the present embodiment comprises:

[0035] (1) take quicklime as neutralizing agent, quicklime and water are configured into the slurry of 200g / L concentration;

[0036] (2) Add 2m into the reaction tank 3 The high-concentration salt-containing waste sulfuric acid, the measured pH value of the high-concentration salt-containing waste sulfuric acid is 1.6, the sulfate ion concentration is 51.9g / L, and the chloride ion concentration is 12.8g / L. Add 7kg of induced agent, stir evenly;

[0037] (3) Gradually add the slurry to the reaction tank, keep stirring during the reaction, the stirring speed is 100r / min, measure the pH value of the material liquid in real time, when the pH value is 4, stop adding the slurry, and continue stirring to 1 Hour;

[0038] (4) Add the calcium chloride powder of 4.4kg in the reaction tank, stir evenly, the stirring speed is 100r / min, and the stirring time is 1 hour; ...

Embodiment 2

[0041] The processing method of high-concentration saline waste sulfuric acid in the present embodiment comprises:

[0042] (1) take quicklime as neutralizing agent, quicklime and water are configured into the slurry of 200g / L concentration;

[0043] (2) Add 2m into the reaction tank 3 The high-concentration salt-containing waste sulfuric acid, the measured pH value of the high-concentration salt-containing waste sulfuric acid is 1.1, the sulfate ion concentration is 58.5g / L, and the chloride ion concentration is 18.3g / L. Add 15kg of induced agent, stir evenly;

[0044] (3) Gradually add the slurry to the reaction tank, keep stirring during the reaction, the stirring speed is 100r / min, measure the pH value of the material liquid in real time, when the pH value is 3, stop adding the slurry, and continue stirring to 1 Hour;

[0045] (4) Add the calcium chloride powder of 2.0kg in the reaction tank, stir evenly, the stirring speed is 100r / min, and the stirring time is 1 hour; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com