Fast evaporation system and method used for high-salt wastewater

A high-salt wastewater, rapid evaporation technology, applied in evaporation, spray evaporation, separation methods, etc., can solve the problems of easy scaling and poor fluidity, and achieve the effects of eliminating hazards, low energy consumption for evaporation, and overcoming easy scaling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

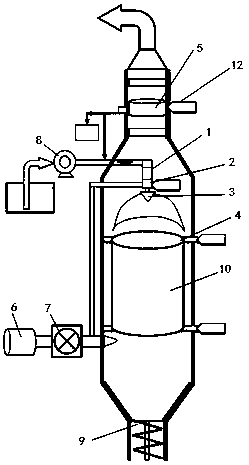

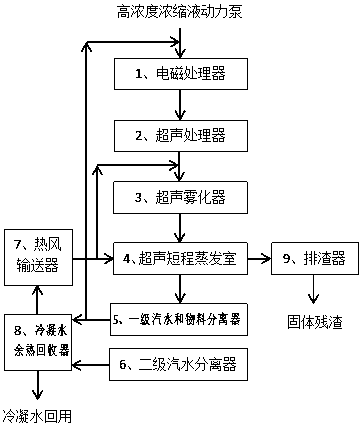

[0025] see figure 1 and 2 , the present invention discloses a rapid evaporation system for high-salt wastewater, which includes a feed pump 8, an electromagnetic processor 1, an ultrasonic processor 2, an ultrasonic atomizer 3, an ultrasonic short-range evaporation chamber 4, and the separation of soda and material. 5, an air dehumidifier 6, a dry air conveyor 7, an ultrasonic spiral deflector 10 and a slag discharger 9; the ultrasonic spiral deflector 10 includes a spiral deflector and a first ultrasonic transducer. The deflector is arranged in the middle of the ultrasonic short-path evaporation chamber 4, and the first ultrasonic transducer is arranged on the outer wall of the ultrasonic short-path evaporation chamber and is connected with the spiral deflector; the electromagnetic processor 1 is arranged on the spiral deflector Above, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com