Method for recovering alumina

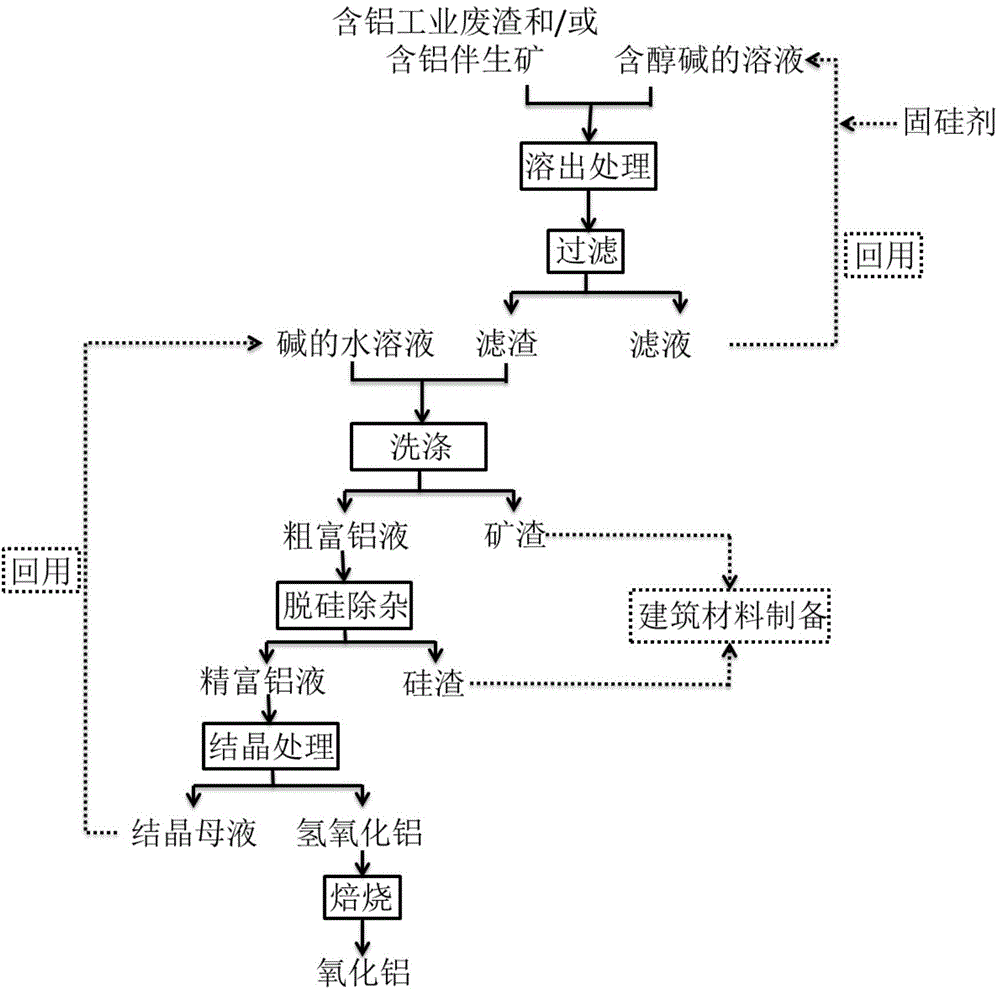

A recovery method and technology of alumina, applied in the direction of alumina/aluminum hydroxide, solid waste removal, etc., can solve the problems of large loss of acid and alkali, high material requirements, corrosion of roasters and wiring pipes, etc. , to achieve the effect of improving recovery rate, high aluminum-silicon separation efficiency, and reducing evaporation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Use ethanol, potassium hydroxide and water to prepare a solution containing alcohol and alkali in a certain proportion, wherein, ethanol and water are configured in a ratio of 9:1 by volume, and potassium hydroxide is used to make the concentration of potassium in the solution containing alcohol and alkali reach 6mol / The amount of L was added.

[0058] Add the fly ash that is crushed and ground to below 80 μm into the prepared alcohol-alkali-containing solution, so that the volume ratio of the alcohol-alkali-containing solution to the mass ratio of the fly ash is 5 liters / kg (liquid-solid ratio). Then the dissolution treatment was carried out at 210° C. for 150 minutes. Filtrate after the dissolution treatment to obtain filtrate and filter residue.

[0059] After the filtrate is added with appropriate amount of potassium hydroxide, ethanol and water to make each parameter consistent with the solution containing alcohol and alkali, it returns to the fly ash dissolution...

Embodiment 2

[0063] Use sodium methoxide and methanol to prepare a solution containing alcohol and alkali, and add sodium methoxide in such an amount that the concentration of sodium in the solution containing alcohol and alkali reaches 2 mol / L.

[0064] Add the fly ash that is crushed and ground to below 80 μm into the prepared alcohol-alkali-containing solution, so that the volume ratio of the alcohol-alkali-containing solution to the mass ratio of the fly ash is 8 liters / kg (liquid-solid ratio). Then, the dissolution treatment was carried out at 260° C. for 90 minutes. Filtrate after the dissolution treatment to obtain filtrate and filter residue.

[0065] The filtrate is added with an appropriate amount of sodium methoxide and methanol to make each parameter consistent with the solution containing alcohol and alkali, and then returns to the fly ash dissolution treatment. The filter residue is washed with an aqueous alkali solution, which is an aqueous sodium hydroxide solution with a ...

Embodiment 3

[0069] Prepare an alcohol-alkali-containing solution with methanol, sodium hydroxide and water, wherein methanol and water are configured in a ratio of 7:3 by volume, and sodium hydroxide is used to make the concentration of sodium in the alcohol-alkali-containing solution reach 12mol / L adding; and adding a silicon-fixing agent, calcium oxide, into the alcohol-alkali-containing solution, and the amount of the silicon-fixing agent added is 1% by mass of the amount of subsequent red mud added.

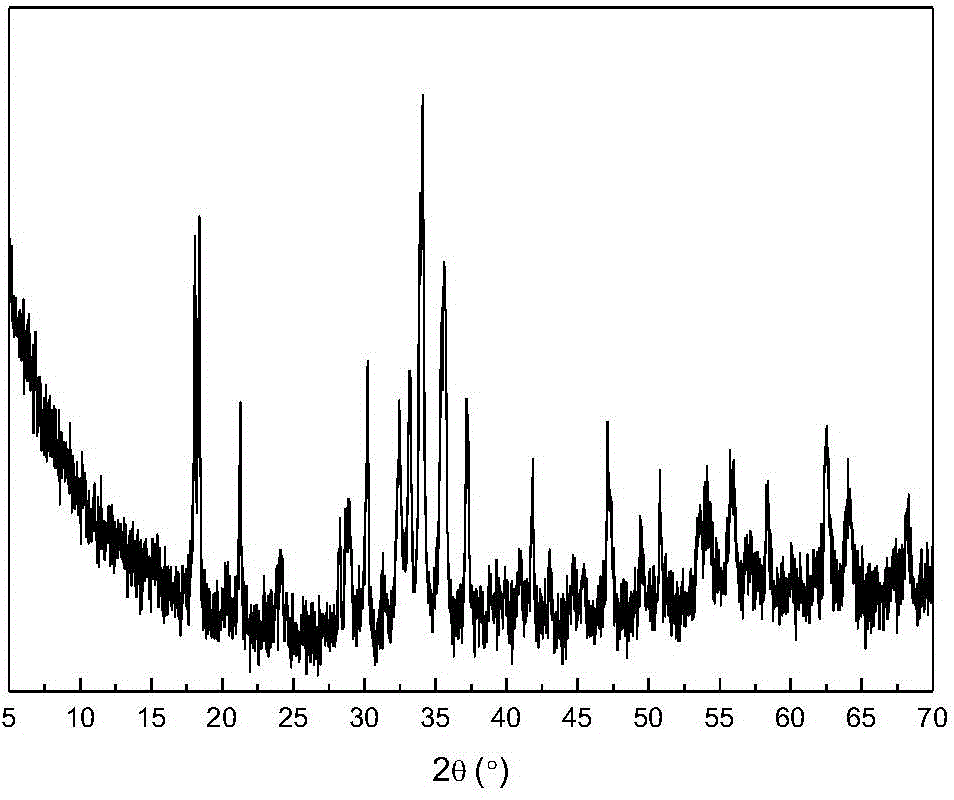

[0070] Add the red mud that is crushed and ground to less than 80 μm into the prepared alcohol-alkali-containing solution, so that the volume ratio of the alcohol-alkali-containing solution to the mass ratio of red mud is 7 liters / kg (liquid-solid ratio). Dissolution treatment was then carried out at 240° C. for 15 minutes. Filtrate after the dissolution treatment to obtain filtrate and filter residue. Filter residue XRD pattern image 3 shown.

[0071] The filtrate is added with appr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com