Method for low-energy consumption condensation of waste liquid produced by alkaline peroxide mechanical pulping

A technology of hydrogen peroxide and mechanical pulping, which is applied in chemical instruments and methods, processing process wastewater treatment, energy wastewater treatment, etc., can solve the secondary pollution of tertiary chemical sludge, high energy consumption of alkali recovery technology, and discharge up to standard to achieve the effects of low operating costs, zero emissions, and reduced evaporation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

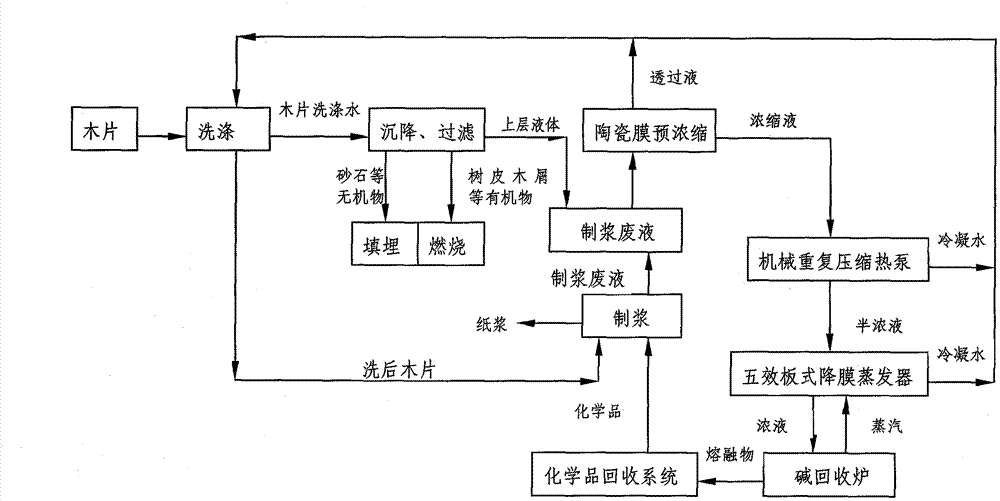

Method used

Image

Examples

Embodiment 1

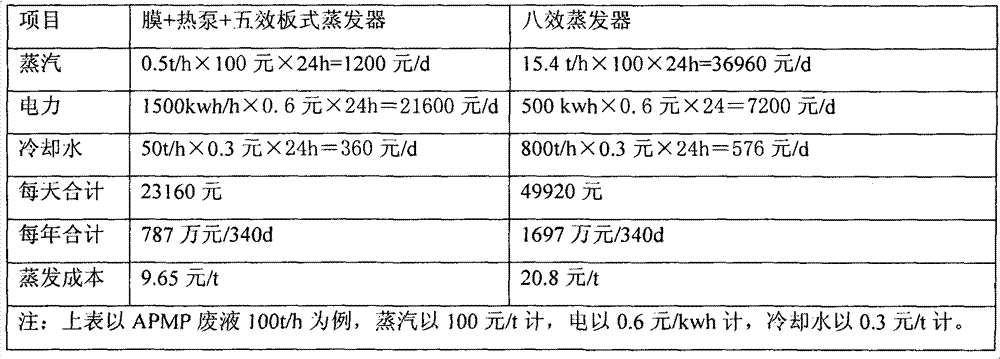

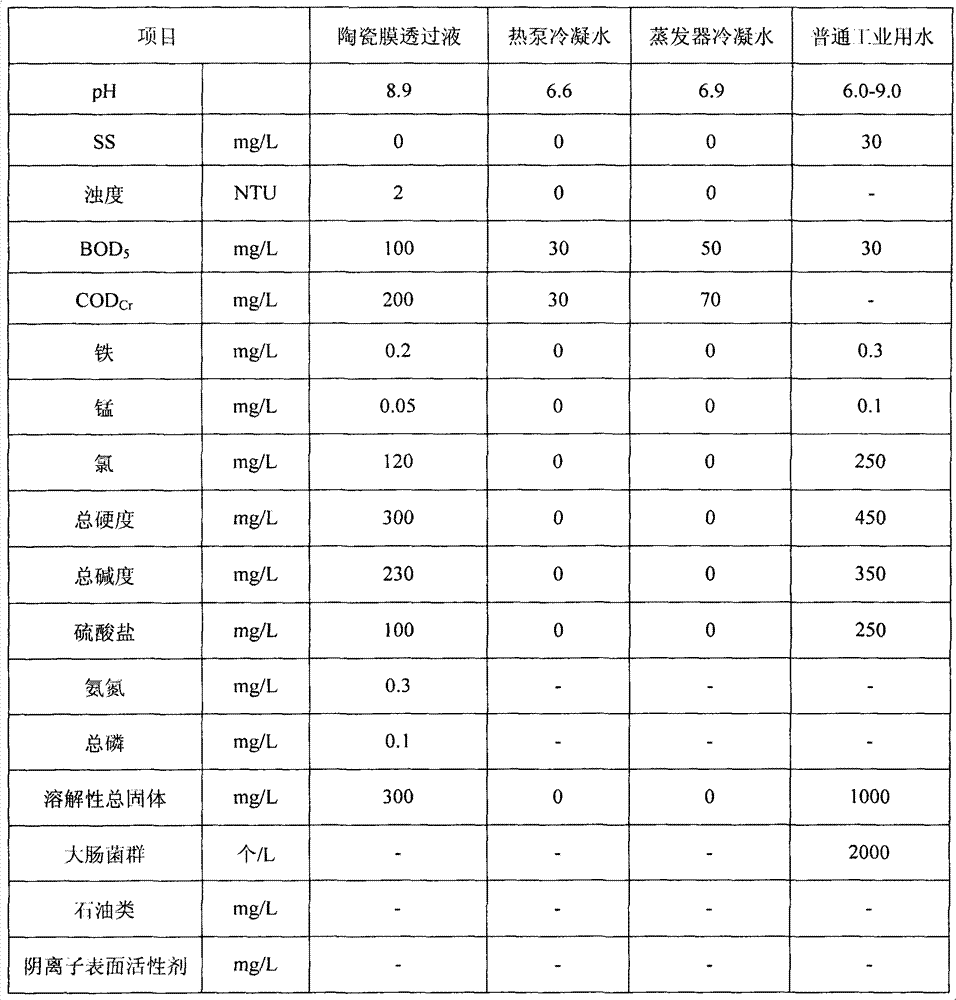

[0022] A wood pulping plant uses purchased wood chips for pulping. The concentration of wood chips in the washing machine is 5%, and the corresponding water consumption is about 19m 3 / t wood chips, COD of wastewater Cr The concentration is 1800mg / L, BOD 5 The concentration is 500mg / L, the SS concentration is 1100mg / L, the pH is 6.4, the color is 660 times, and the water temperature is 80-90°C.

[0023] The waste liquid generated in the process of alkaline hydrogen peroxide mechanical pulping includes: squeeze tearer waste liquid, bleached screw press waste liquid, and slurry cone cleaner / pressure screen treatment waste liquid. The waste liquid of the chemical pulp squeezing and tearing machine contains a large amount of wood chips. After being treated by a cylindrical fine-grid sieve, the COD is about 13000mg / L. After the sieve, the waste liquid flows to the waste liquid intermediate tank, and then passes through the 0.10mm sieve. The pressure filter screen performs fine filtrati...

Embodiment 2

[0035] A wood pulping plant uses purchased wood chips for pulping. The concentration of wood chips in the washing machine is 5%, and the corresponding water consumption is about 19m 3 / t wood chips, COD of wastewater Cr The concentration is 1800mg / L, BOD 5 The concentration is 500mg / L, the SS concentration is 1100mg / L, the pH is 6.4, the color is 660 times, and the water temperature is 80-90°C.

[0036] The waste liquid generated in the process of alkaline hydrogen peroxide mechanical pulping includes: squeeze tearer waste liquid, bleached screw press waste liquid, and slurry cone cleaner / pressure screen treatment waste liquid. The waste liquid of the chemical pulp squeezing and tearing machine contains a large amount of wood chips. After being treated by a cylindrical fine-grid sieve, the COD is about 13000mg / L. After the sieve, the waste liquid flows to the waste liquid intermediate tank, and then passes through the 0.10mm sieve. The pressure filter screen performs fine filtrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com