Black liquor treatment method combining lignin extraction and synthesis gas production

A treatment method and synthesis gas technology, applied in fiber raw material treatment, lye regeneration, textile and papermaking, etc., can solve the problems of large evaporation of dilute black liquor, large concentration of dilute black liquor, and inability to recover lignin, etc. Achieve the effect of reducing energy consumption and reducing evaporation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

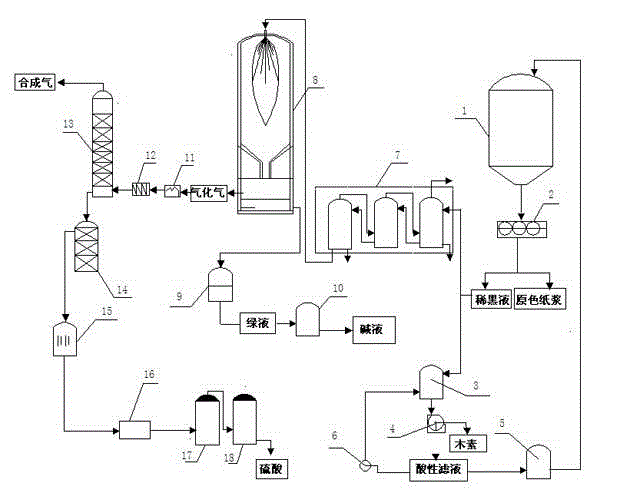

[0044] Such as figure 1 , a kind of black liquor processing method that lignin extraction combines syngas production, comprises the following steps:

[0045] a. Lignin extraction: extract and separate the slurry produced by cooking in the cooking pot 1 with the black liquor extractor 2 to obtain dilute black liquor and primary color pulp, and import the dilute black liquor with 50% by weight into the black liquor acidification pool 3. Add sulfuric acid to adjust the pH value to 4, precipitate the lignin, and filter it with a vacuum filter 4 to obtain lignin and acidic filtrate;

[0046] b. Acidic filtrate recycling: a part of the acidic filtrate is introduced into the filtrate alkalization pool 5, and its volume is equal to that of the dilute black liquor entering the black liquor acidification pool 3. After alkalization with alkali (pH is 10), the circulation Put it into cooking pot 1 for cooking, add wood chips, water, recovered lye and anthraquinone and other chemical add...

Embodiment 2

[0054] Such as figure 1 , a kind of black liquor processing method that lignin extraction combines syngas production, comprises the following steps:

[0055] a. Lignin extraction: extract and separate the slurry produced by cooking in the cooking pot 1 with the black liquor extractor 2 to obtain dilute black liquor and primary color pulp, and import the dilute black liquor with a weight percentage of 30% into the black liquor acidification pool 3. Adding sulfuric acid to adjust the pH value to 3, causing the lignin to precipitate, and filtering with a vacuum filter 4 to obtain the lignin and the acidic filtrate;

[0056] b. Acidic filtrate recycling: a part of the acidic filtrate is introduced into the filtrate alkalization pool 5, and its volume is equal to the dilute black liquor entering the black liquor acidification pool 3. Put it into cooking pot 1 for cooking, add wood chips, water, recovered lye and anthraquinone and other chemical additives, feed water steam for coo...

Embodiment 3

[0064] Such as figure 1 , a kind of black liquor processing method that lignin extraction combines syngas production, comprises the following steps:

[0065] a. Lignin extraction: the slurry produced by cooking in the cooking pot 1 is extracted and separated by the black liquor extractor 2 to obtain dilute black liquor and primary color pulp, and the dilute black liquor with a weight percentage of 40% is introduced into the black liquor acidification pool 3. Adding sulfuric acid to adjust the pH value to 2, causing lignin to precipitate out, and filtering with vacuum filter 4 to obtain lignin and acidic filtrate;

[0066] b. Acidic filtrate recycling: a part of the acidic filtrate is introduced into the filtrate alkalization pool 5, and its volume is equal to that of the dilute black liquor entering the black liquor acidification pool 3. Put it into cooking pot 1 for cooking, add wood chips, water, recycled lye and green oxygen and other chemical additives, feed water steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com