Producing process of battery-level lithium hydroxide

A lithium hydroxide and production process technology, applied in the direction of lithium oxide;/hydroxide, battery electrodes, circuits, etc., can solve the problems of complex process flow, large amount of by-products, difficult to filter, etc., and achieve high product purity, The effect of fewer by-products and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

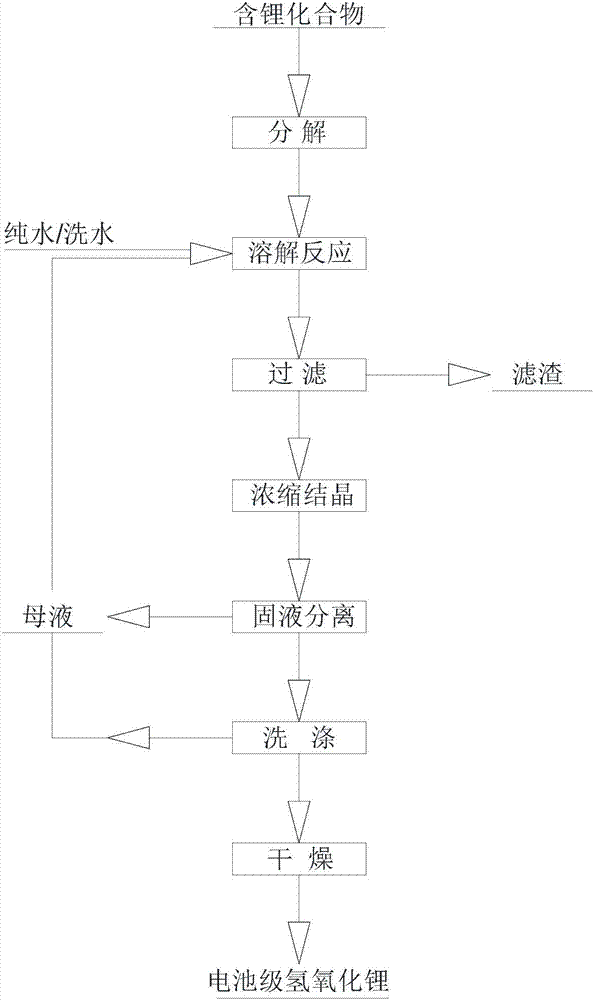

Method used

Image

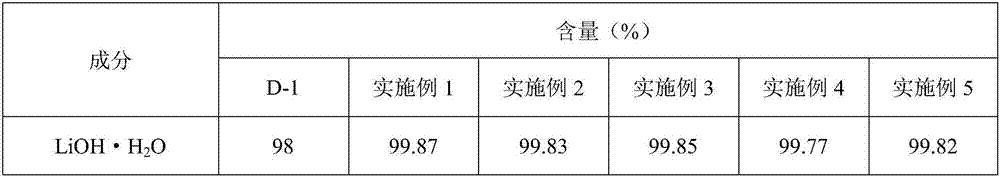

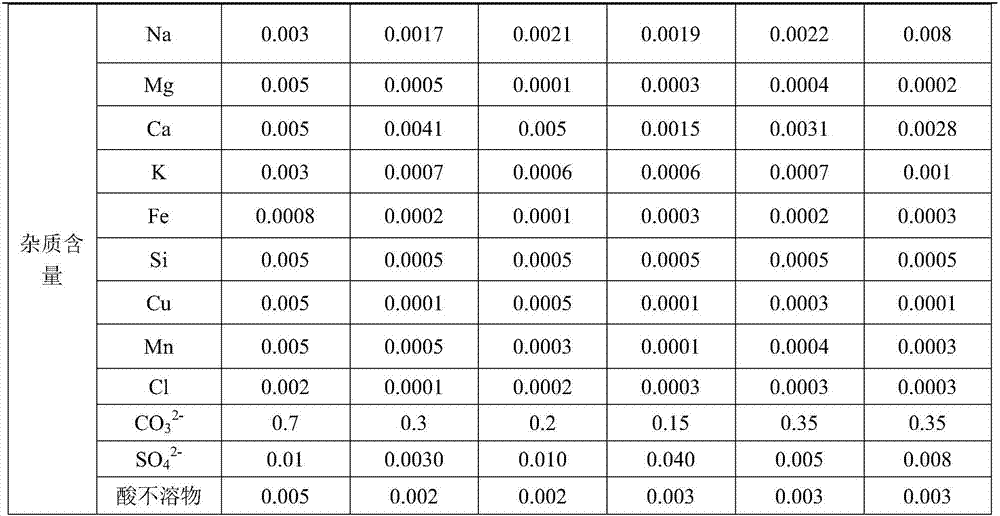

Examples

Embodiment 1

[0073] Put 2kg of industrial-grade lithium carbonate with a particle size of 5-7μm into a plasma decomposition furnace with a temperature of 1600°C and a pressure of 2000Pa in the furnace through nitrogen atomization for decomposition. The residence time is 0.005h, and 1kg of decomposition products are obtained. The lithium content is 74.5%, and the decomposition rate is 92%.

[0074] Dissolve the above decomposition products in pure water at 30°C while stirring at a solid-to-liquid mass ratio of 1:10, react for 0.5 hours, and the temperature of the solution rises to 85°C.

[0075] The solution obtained by dissolving is filtered while it is hot, and the filter residue is washed with a small amount of pure water to obtain filtered and refined lithium hydroxide solution and filter residue.

[0076] Evaporate and crystallize the lithium hydroxide solution obtained by filtration, control the solid content of the evaporated magma to 5%, then cool to 35°C, centrifuge, and rinse with...

Embodiment 2

[0079] 3 kg of industrial-grade lithium carbonate with a particle size of 90-100 μm was loaded into a plasma decomposition furnace with a temperature of 1500 ° C and a pressure of 1500 Pa in the furnace through nitrogen atomization for decomposition. The residence time was 0.01 h, and 1.46 kg of decomposition products were obtained. The lithium oxide content in the product is 66.5%, and the decomposition rate is 80%.

[0080] The above decomposition products were dissolved in pure water at 40°C while stirring at a solid-to-liquid mass ratio of 0.8:10, and reacted for 1.0 hour, and the temperature of the solution rose to 95°C.

[0081] The solution obtained by dissolving is filtered while it is hot, and the filter residue is washed with a small amount of pure water to obtain the filtered lithium hydroxide solution and filter residue.

[0082] Evaporate and crystallize the lithium hydroxide solution obtained by filtration, the solid content of the crystal slurry is 7%, stop the ...

Embodiment 3

[0085] 2kg of industrial-grade lithium sulfate with a particle size of 45-100μm was decomposed by nitrogen atomization into a plasma decomposition furnace with a loading temperature of 1600°C and a furnace pressure of 1000Pa. The residence time was 0.02h, and 0.6kg of decomposition products were obtained. The content of lithium oxide in the product was 80% %, the decomposition rate is 88%.

[0086]The above decomposition products were dissolved in pure water at 30°C while stirring at a solid-to-liquid mass ratio of 0.8:10, and reacted for 1.0 hour, and the temperature of the solution rose to 86°C.

[0087] The solution obtained by dissolving is filtered while it is hot, and the filter residue is washed with a small amount of pure water to obtain pure lithium hydroxide solution and filter residue.

[0088] Evaporate and crystallize the filtered lithium hydroxide solution, stop concentrating the magma with a solid content of 5%, cool to 40°C, centrifuge, and rinse with pure wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com