Method for extracting high-purity sodium thiocyanate and sodium thiosulfate in gas desulfurization waste salt

A technology of sodium thiosulfate and sodium thiocyanate, applied in the directions of thiocyanic acid, thiosulfate/dithionite/polythionite, etc., can solve the problem of high production cost, achieve low production cost, Low energy consumption and controllable average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

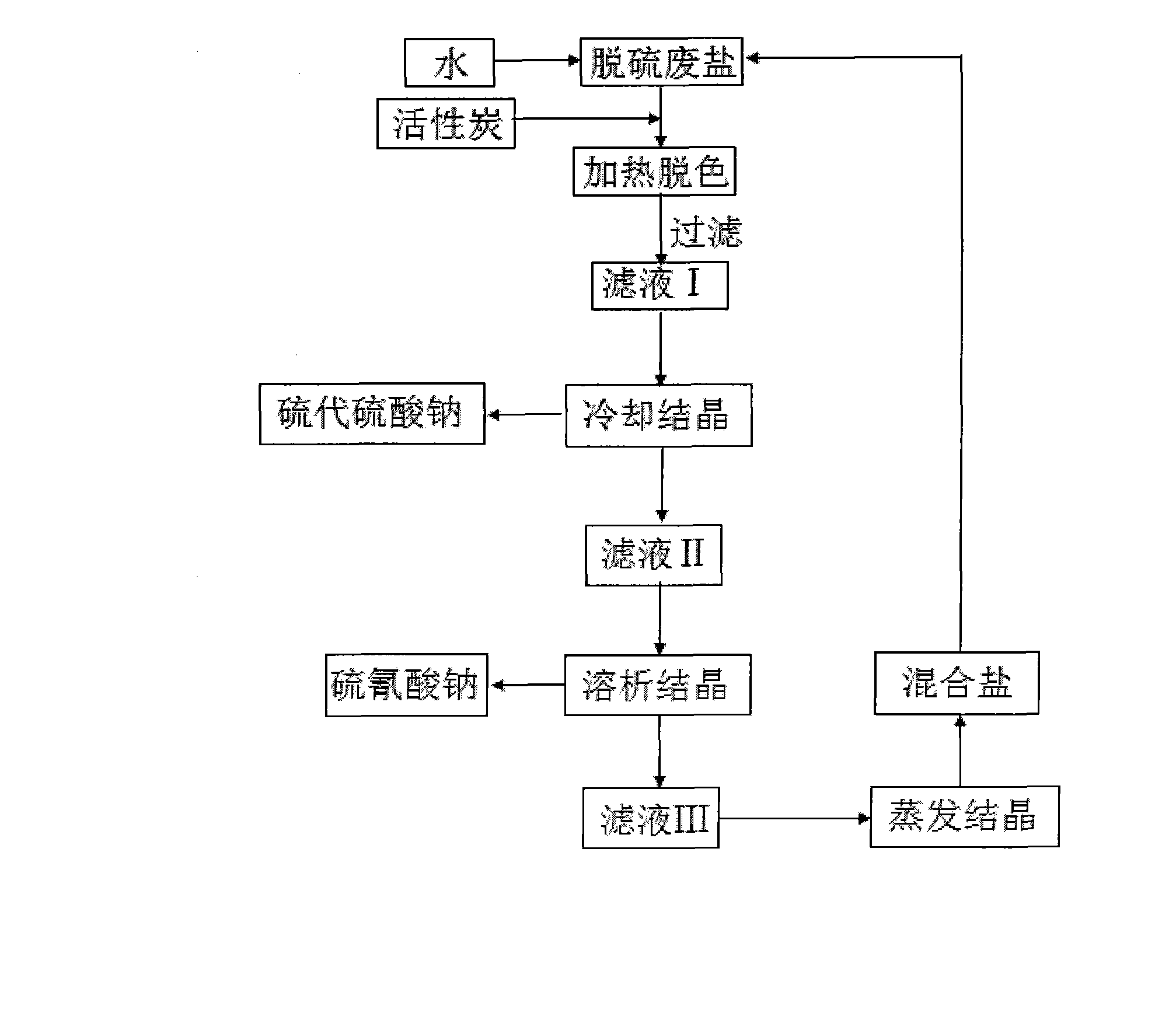

Image

Examples

Embodiment 1

[0022] A method for extracting high-purity sodium thiocyanate and sodium thiosulfate from gas desulfurization waste salt, the specific steps are:

[0023] Step 1, first prepare desulfurization waste salt, water and crystal mixed salt into a solution, wherein the concentration of sodium thiocyanate is 30-40wt%, and the concentration of sodium thiosulfate is 55-65wt%; Under the conditions of 50°C and 300-500r / min rotation speed, add activated carbon accounting for 3-4wt% of desulfurization waste salt while stirring, keep stirring and decolorize for 0.5-0.7h; then filter at 40-50°C and use 10-30 ℃ of water washing 1 to 2 times, the resulting filtrate I is the primary crystallization mother liquor;

[0024] Step 2: Add sodium thiosulfate seed crystals accounting for 0.5-1.0 wt% of desulfurization waste salt to the primary crystallization mother liquor prepared in step 1 under the conditions of normal pressure, 40-50°C and a rotating speed of 300-500r / min, Insulate and stir the cr...

Embodiment 2

[0029] A method for extracting high-purity sodium thiocyanate and sodium thiosulfate from gas desulfurization waste salt, the specific steps are:

[0030] Step 1, first prepare desulfurization waste salt, water and crystal mixed salt into a solution, wherein the concentration of sodium thiocyanate is 35-45wt%, and the concentration of sodium thiosulfate is 50-60wt%; Under the conditions of 55°C and 300-500r / min rotation speed, add activated carbon accounting for 3.5-4.5wt% of desulfurization waste salt while stirring, keep stirring and decolorize for 0.7-0.9h; then filter at 45-55°C, use 10- Washing with water at 30°C for 1 to 2 times, the resulting filtrate I is the primary crystallization mother liquor;

[0031]Step 2: Add sodium thiosulfate seed crystals accounting for 0.8-1.3 wt% of desulfurization waste salt to the primary crystallization mother liquor prepared in step 1 under normal pressure, 45-55°C and a rotating speed of 300-500r / min, Insulate and stir the crystal fo...

Embodiment 3

[0036] A method for extracting high-purity sodium thiocyanate and sodium thiosulfate from gas desulfurization waste salt, the specific steps are:

[0037] Step 1, first prepare desulfurization waste salt, water and crystal mixed salt into a solution, wherein the concentration of sodium thiocyanate is 40-50wt%, and the concentration of sodium thiosulfate is 45-55wt%; Under the conditions of 60°C and 300-500r / min rotation speed, add activated carbon accounting for 4-5wt% of desulfurization waste salt while stirring, keep stirring and decolorize for 0.8-1.0h; then filter at 50-60°C and use 10-30 ℃ of water washing 1 to 2 times, the resulting filtrate I is the primary crystallization mother liquor;

[0038] Step 2: Add sodium thiosulfate seed crystals accounting for 1.0-1.5 wt% of desulfurization waste salt to the primary crystallization mother liquor prepared in step 1 under the conditions of normal pressure, 50-60°C and a rotating speed of 300-500r / min, Insulate and stir the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com