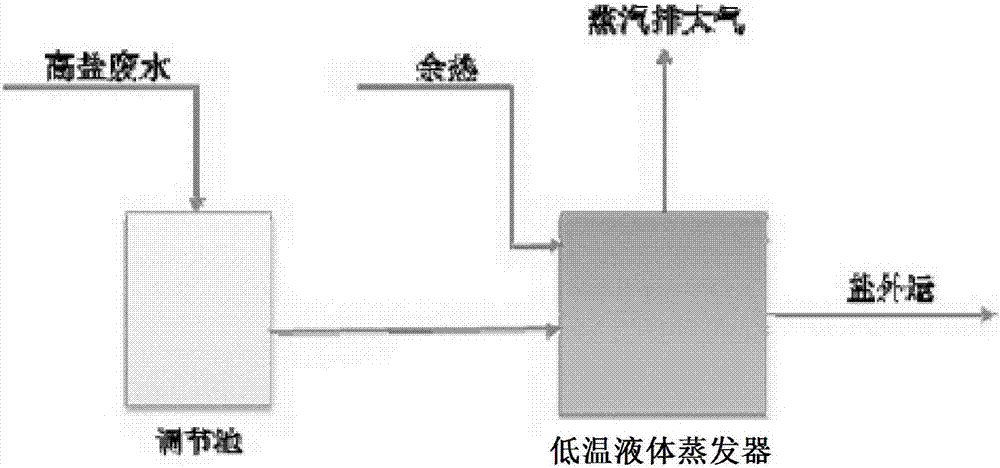

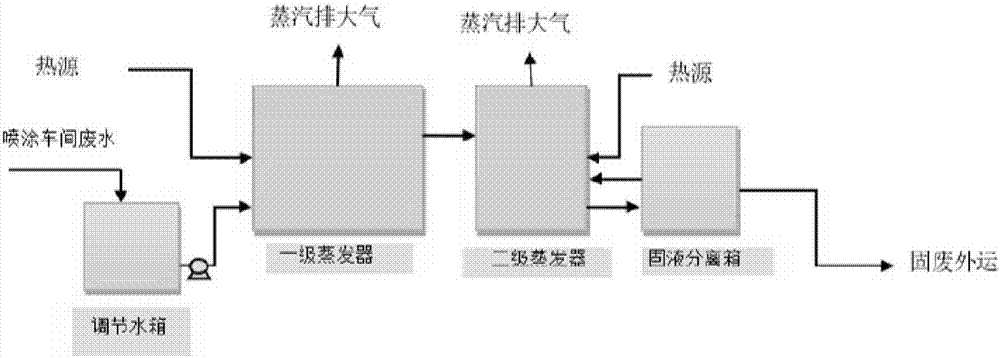

Low-temperature liquid evaporator

A low-temperature liquid and evaporator technology, applied in evaporator accessories, forced circulation evaporators, evaporation, etc., can solve the problems of inaccurate control of furnace temperature, volatilization of harmful organic substances, loss of heat energy transfer, etc., and achieve the goal of reducing gas pollution risk, reduce evaporation energy consumption, and increase the effect of evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

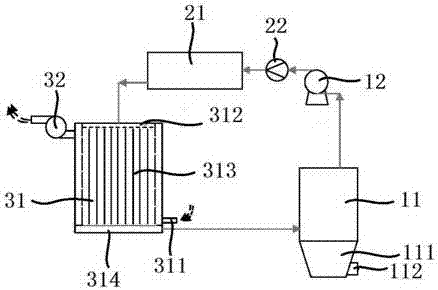

[0026] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0027] As principle of the present invention is described as follows:

[0028] At a certain temperature, the pressure generated by the water vapor part in the humid air is called the water vapor partial pressure, and the total pressure of the wet air is the sum of the dry air pressure and the water vapor partial pressure. Under certain conditions of temperature and pressure, there is a limit to the amount of water vapor that a certain volume of dry air can hold. When the water vapor content in humid air does not reach this limit, it is called unsaturated humid air, and when it reaches the limit, it is called saturated humidity. For air, the corresponding water vapor partial pressure is called saturated water vapor partial pressure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com