Method for controlling furnace pressure of pulse furnace

A furnace pressure control and pulse furnace technology, which is applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of walking beams affecting the atmosphere in the furnace, poor portability, and occupation of self-learning functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

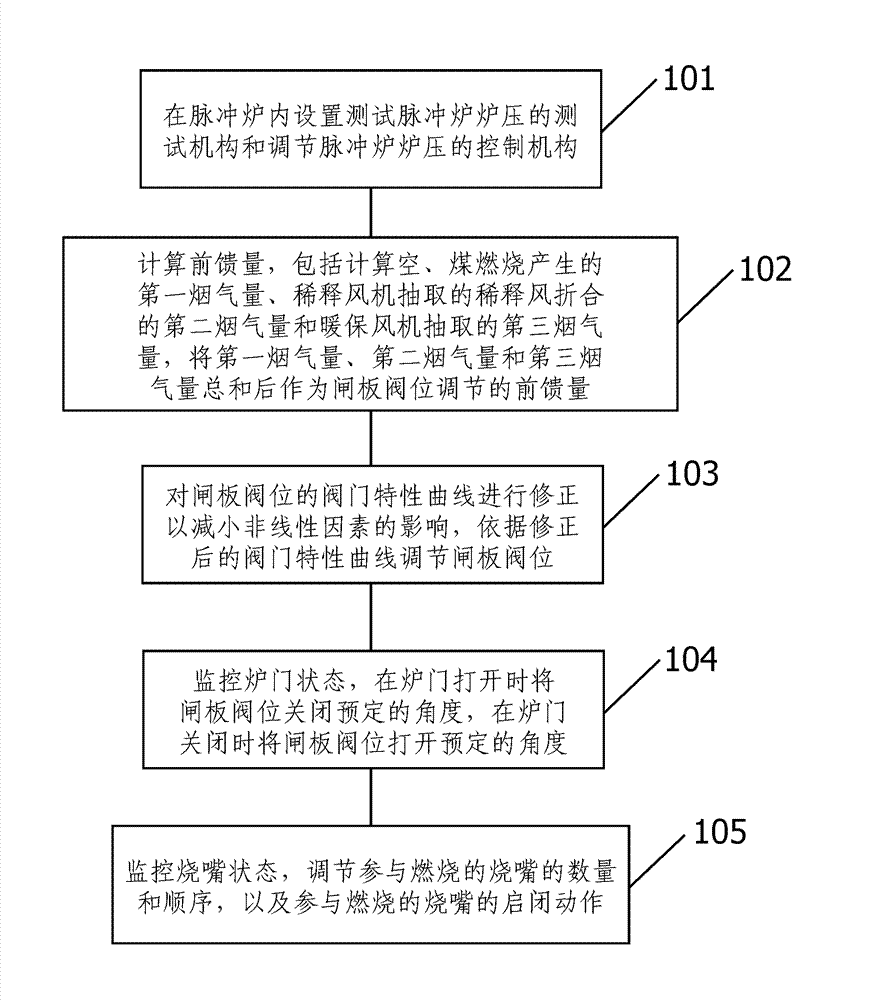

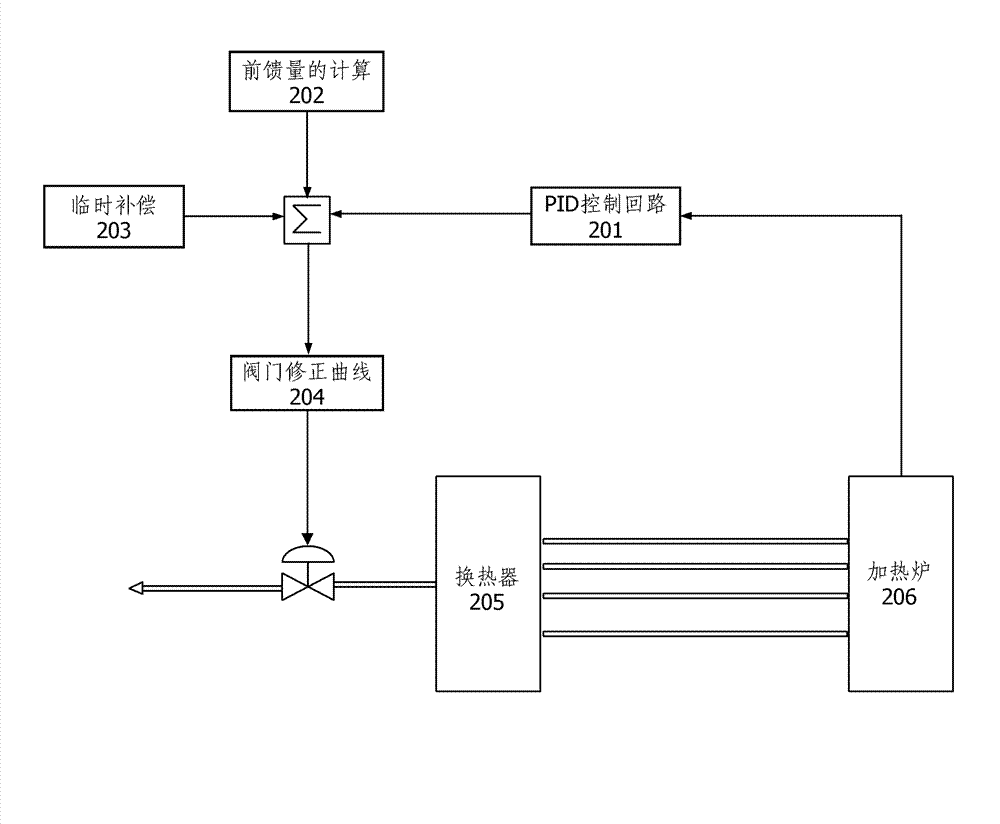

[0036] According to the actual investigation, analysis and test of the working process of the pulse furnace, the present invention finds that the furnace pressure control strategy of PID+feedforward control+temporary compensation can effectively realize the stable control of the furnace pressure. The advantage of this combined control strategy is that it not only retains the accuracy of PID control but also reflects the rapidity of feedforward control. Temporary compensation makes the valve move in advance to reduce the influence of disturbance factors on furnace pressure.

[0037] The root of controlling the furnace pressure of a pulse furnace lies in how to balance the relationship between the flue gas variation in the furnace and the opening of the gate valve position. After analysis, it is found that the disturbance factors affecting the furnace pressure mainly include: burner logarithm, combustion capacity, gate valve Position characteristics, the position of the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com