A precise gas concentration control device for injection-assisted sintering method and its control method

A technology of injection device and control device, which is applied to furnace control device, furnace, lighting and heating equipment, etc., can solve problems such as energy waste, explosion production accident, increase of gas burning point, etc., to improve the degree of freedom and adjustability , The effect of improving the adaptability of the device and reducing the energy consumption index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

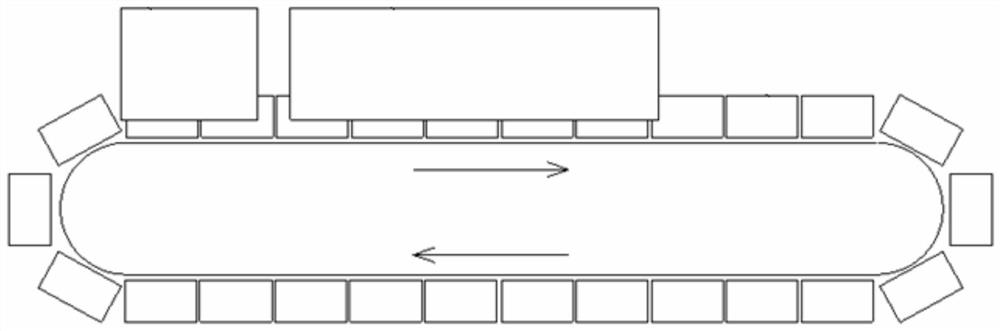

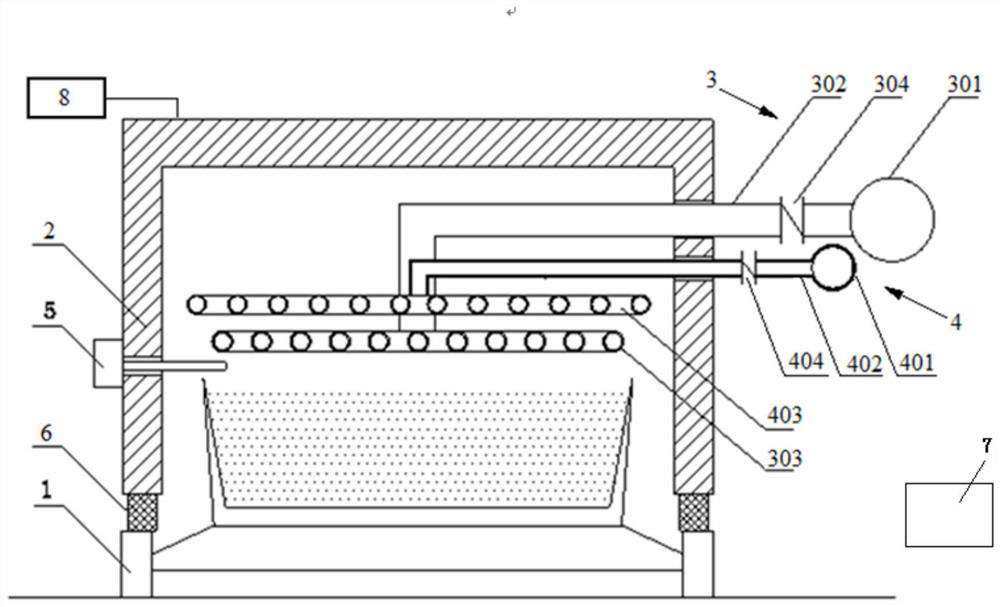

[0080] A precise gas concentration control device for injection-assisted sintering, comprising a sintering machine trolley 1 and an injection hood 2 . The blowing cover 2 is located on the upper part of the sintering machine trolley 1 and forms a sealed body with the sintering machine trolley 1 . The device also includes a gas injection device 3 and a material level CO detection device 5 arranged on the injection hood 2 . The gas injection device 3 includes a gas injection main pipe 301, 6 gas injection branch pipes 302 and a gas injection pipe row connected with each gas injection branch pipe 302 by 12 gas injection pipes 303 arranged in parallel. The gas injection main pipe 301 is arranged on the outside of the blowing hood 2. One end of the gas injection branch pipe 302 is connected to the gas injection main pipe 301 and the other end is connected to 12 gas injection pipes 303. The gas injection branch pipe 302 extends into the blowing cover 2. The material level CO detect...

Embodiment 2

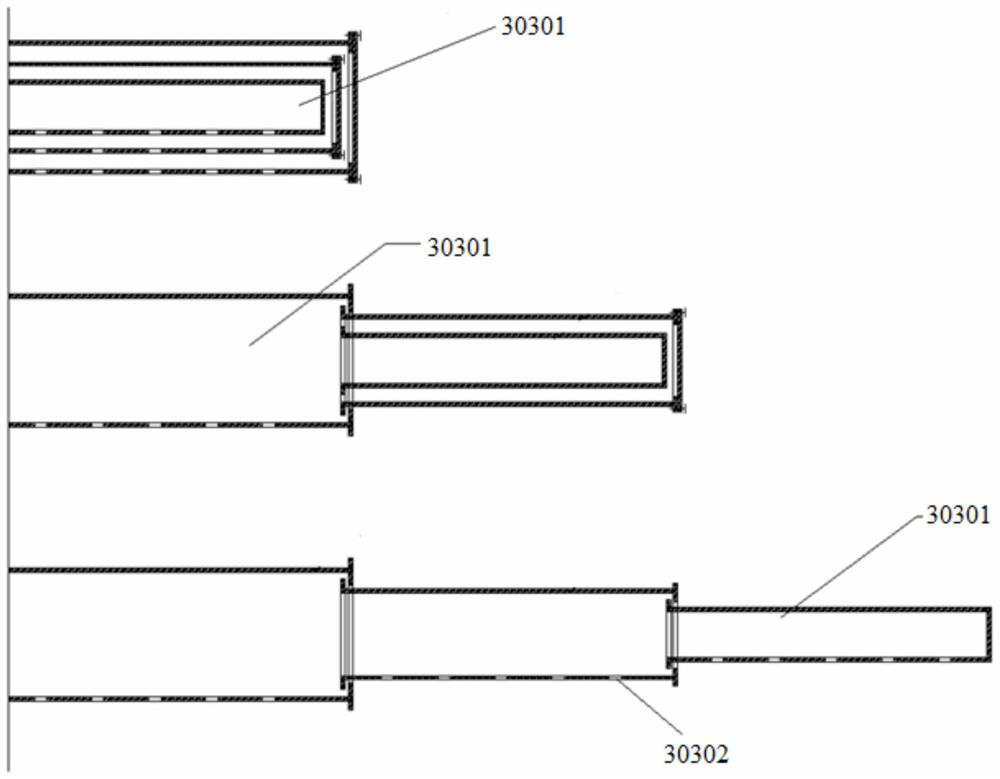

[0082] Repeat Example 1, except that the gas injection pipe 303 is a 3-section gas injection sleeve 30301. The air blowing pipe 403 is a 3-section air blowing sleeve 40301.

Embodiment 3

[0084] Embodiment 1 is repeated, except that the gas injection main pipe 301 is provided with eight gas injection branch pipes 302 . Eight gas injection pipes 303 are arranged on one side of each gas injection branch pipe 302 . The main air blowing pipe 401 is provided with eight air blowing branch pipes 402 . Eight air blowing pipes 403 are arranged on one side of each air blowing branch pipe 402 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com