Method for producing fireproof black cotton by using red mud

A technology of red mud and black cotton, applied in the field of comprehensive utilization of solid waste resources, can solve problems affecting the sustainable development of the aluminum industry, multi-yard construction and maintenance costs, dust flying with the wind, etc., to achieve small high-temperature line shrinkage, high Effect of melting point, hygroscopicity and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

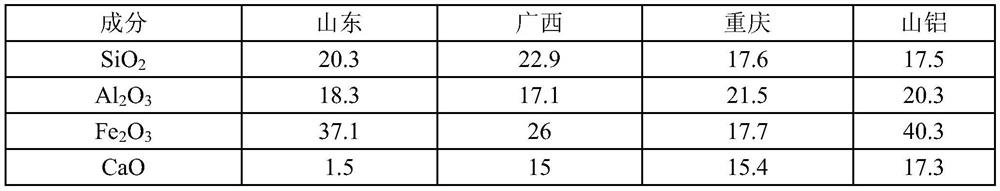

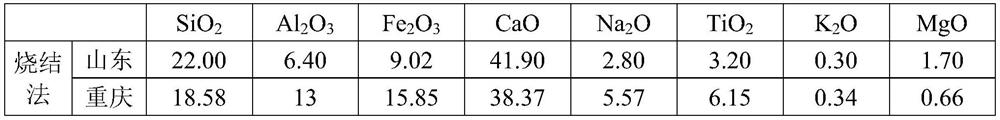

[0031] Taking the high iron red mud generated after using the Bayer method to prepare alumina in Table 1 Shandong region as a raw material to produce fire-resistant black cotton, the concrete method is as follows:

[0032] (1) Ingredients

[0033] After calculation, 70 parts of red mud are used, and other ingredients are as follows: 3 parts of silica sand, 4 parts of reducing agent C (reducing agent is not included in the content of red mud ingredients balls), and 27 parts of limestone. The acidity coefficient of the mixed red mud ingredient balls is 1.9, and the viscosity coefficient is 1.

[0034] (2)Mixing balls

[0035] After the red mud and ingredients are uniformly mixed, a ball-shaped charge with a diameter of 3.5 cm is made to obtain red mud ingredients balls. The red mud batching pellets are naturally dried by storage, and the mechanical strength requires that the free fall damage rate is less than 1% at a height of 1m.

[0036] (3) Drying, preheating and dehydrati...

Embodiment 2

[0047] Take the high-speed iron red mud of table 1 Chongqing Bayer method as raw material ingredient to produce fire-resistant black cotton fiber, and the concrete method is as follows:

[0048] (1) Ingredients

[0049] After calculation, 87 parts of red mud are used, and other ingredients are as follows: Other ingredients are as follows: 3 parts of silica sand, 10 parts of dolomite sand. The acidity coefficient of the mixed red mud ingredient pellets is 2.0, and the viscosity coefficient is 1.1.

[0050] (2)Mixing balls

[0051] After the red mud and ingredients are uniformly mixed, a ball-shaped charge with a diameter of 3.5 cm is made to obtain red mud ingredients balls. The red mud batching pellets are naturally dried by storage, and the mechanical strength requires that the free fall damage rate is less than 1% at a height of 1m.

[0052] (3) Drying, preheating and dehydration

[0053]It is produced in an electric melting furnace. The red mud batching balls are dried ...

Embodiment 3

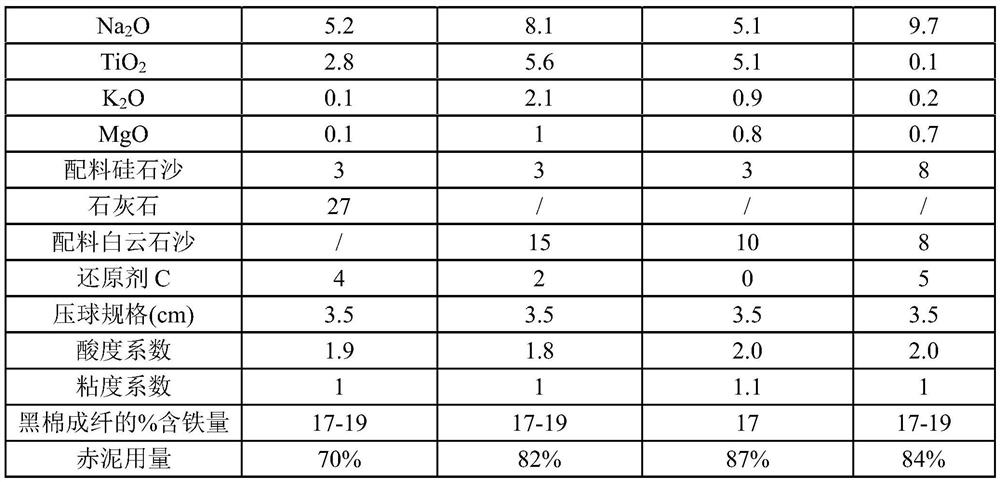

[0064] Produce red mud black cotton fiber with table 3-Chongqing Bayer method, sintering method red mud mixed ingredients, concrete method is as follows:

[0065] (1) Ingredients

[0066] After calculation, 90 parts of mixed red mud (including 70 parts of Bayer process red mud and 30 parts of sintering process red mud) were used. The other ingredients are as follows: 10 parts of silica sand. The acidity coefficient of the mixed red mud ingredient pellets is 2.0, and the viscosity coefficient is 1.0.

[0067] (2)Mixing balls

[0068] After the red mud and ingredients are uniformly mixed, a ball-shaped charge with a diameter of 3.5 cm is made to obtain red mud ingredients balls. The red mud batching pellets are naturally dried by storage, and the mechanical strength requires that the free fall damage rate is less than 1% at a height of 1m.

[0069] (3) Drying, preheating and dehydration

[0070] It is produced in an electric melting furnace. The red mud batching balls are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com