Multi-stage intensifying auxiliary sintering type ignition holding furnace and use method of same

An ignition holding furnace and auxiliary sintering technology, which is applied in the sintering field and can solve problems such as increased maintenance costs, finished sintered ore transfer strength, negative effects of reduction degree and low-temperature reduction pulverization rate, and low sintering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

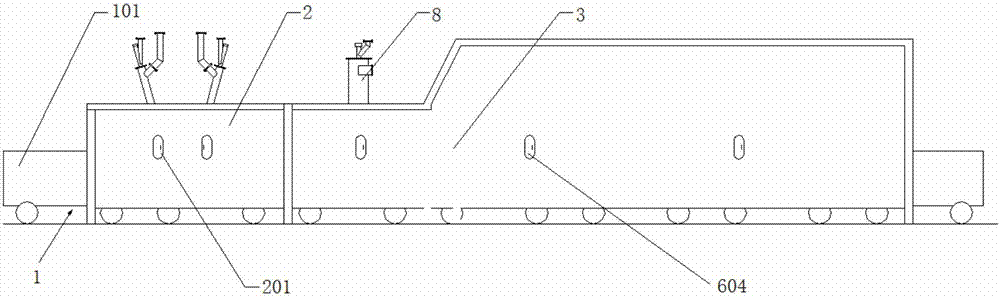

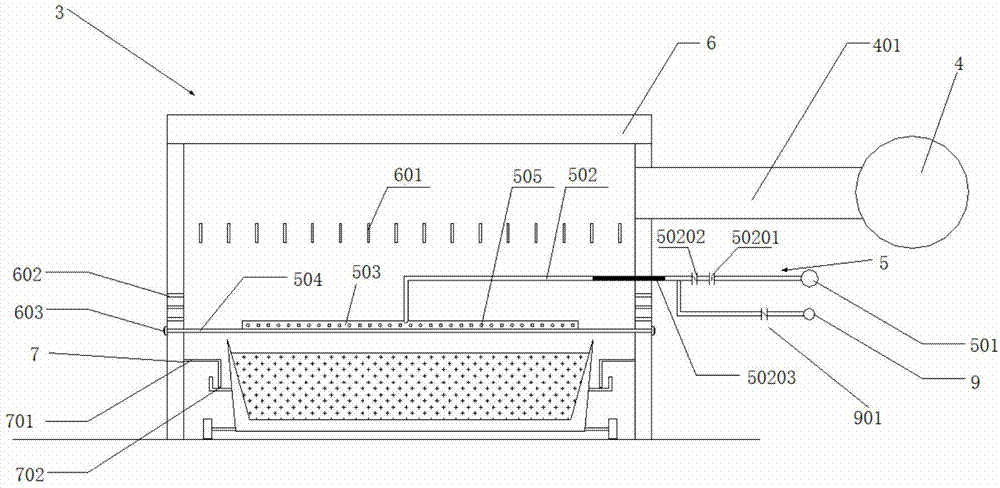

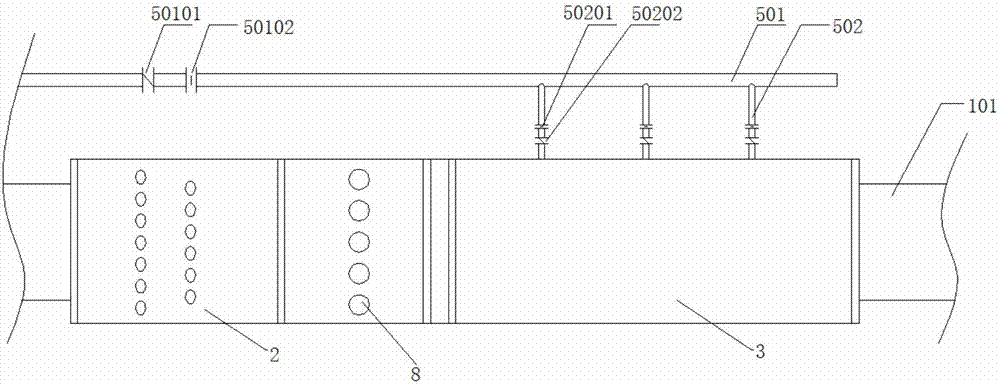

[0090] According to the first embodiment provided by the present invention, a multi-stage enhanced auxiliary sintering type ignition and holding furnace is provided:

[0091] A multi-stage enhanced auxiliary sintering type ignition and holding furnace device includes a sintering machine 1, an ignition device 2 and an auxiliary combustion device 3. The sintering machine 1 includes a trolley 101 , and along the running direction of the trolley 101 , the ignition device 2 and the auxiliary combustion device 3 are sequentially arranged above the trolley 101 . The auxiliary combustion device 3 includes a hot air device 4 , an injection device 5 and an auxiliary combustion cover 6 . The hot air device 4 and the blowing device 5 are arranged on the auxiliary combustion cover 6 . The hot air device 4 includes a hot air duct 401 . The hot blast duct 401 stretches into or leads into the auxiliary combustion cover 6 . The blowing device 5 includes a gas main pipe 501 , a gas branch pi...

Embodiment 1

[0128] A multi-stage enhanced auxiliary sintering type ignition and holding furnace device includes a sintering machine 1, an ignition device 2 and an auxiliary combustion device 3. The sintering machine 1 includes a trolley 101 , and along the running direction of the trolley 101 , the ignition device 2 and the auxiliary combustion device 3 are sequentially arranged above the trolley 101 . The auxiliary combustion device 3 includes a hot air device 4 , an injection device 5 and an auxiliary combustion cover 6 . The hot air device 4 and the blowing device 5 are arranged on the auxiliary combustion cover 6 . The hot air device 4 includes a hot air duct 401 . The hot blast duct 401 stretches into or leads into the auxiliary combustion cover 6 . The blowing device 5 includes a gas main pipe 501 , a gas branch pipe 502 , a blowing pipe 503 and a bracket 504 . The gas main pipe 501 is arranged outside the auxiliary combustion cover 6 . One end of the gas branch pipe 502 is conn...

Embodiment 2

[0130] Embodiment 1 is repeated, except that the inner space of the auxiliary combustion cover 6 is also provided with a rectifying device 601 . The rectifying device 601 is located above the blowing pipe 503 of the blowing device 5 but below the air outlet of the hot blast duct 401 of the hot blast device 4 . The rectifying device 601 is a rectifying plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com