Method for reburning denitration of cement kiln by using alternative fuel

An alternative fuel and reburning technology, applied in the field of combustion, can solve the problems such as difficult to meet the emission targets of nitrogen oxides, and achieve the effect of protecting clean level, low operating cost and good comprehensive environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

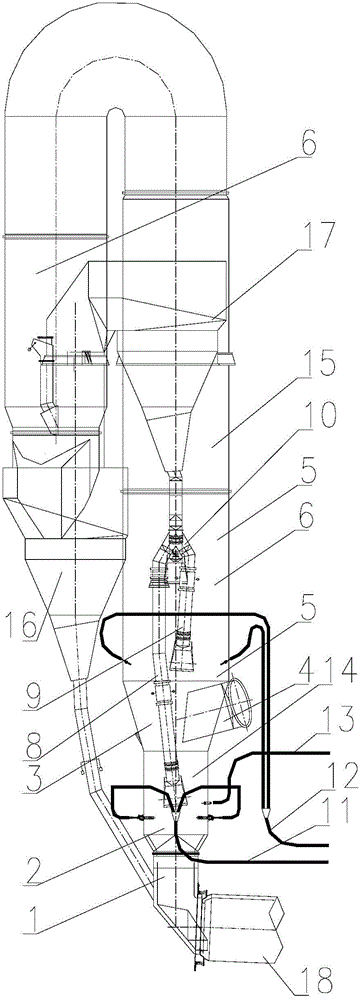

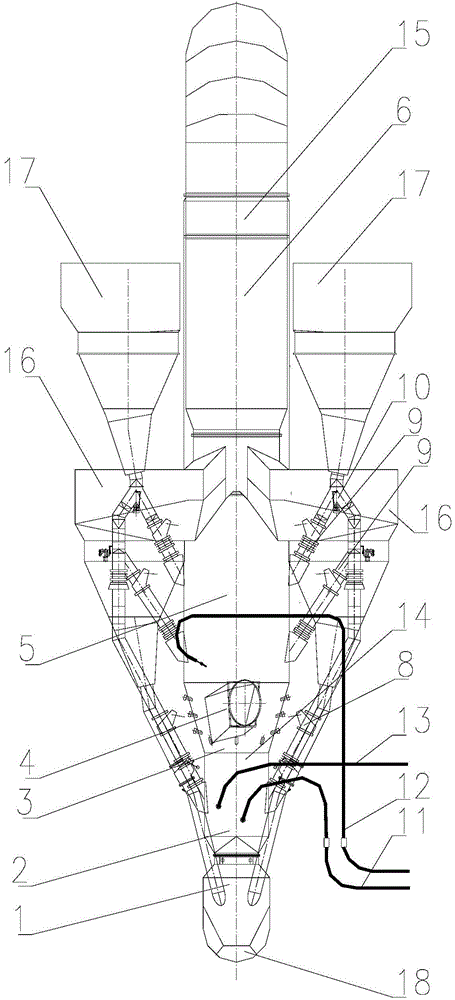

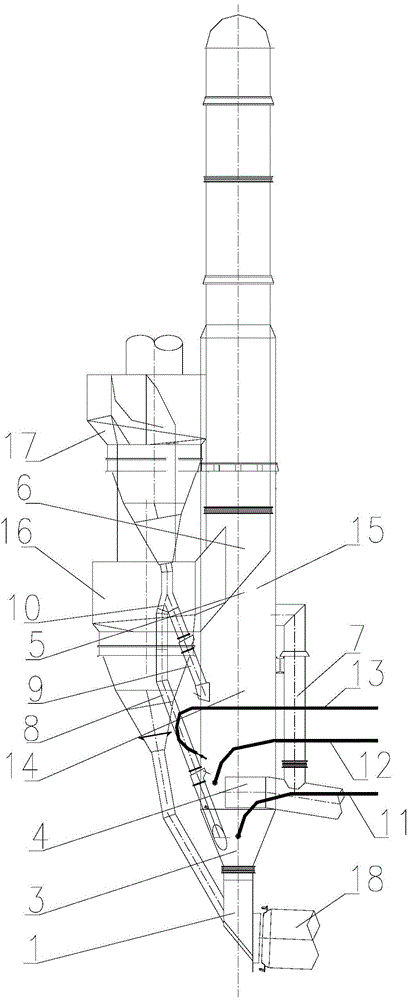

[0037] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0038] See Figure 1 ~ Figure 4Generally, the calciner adopting the staged combustion technology can be divided into two parts, the calciner reduction combustion area 14 and the calciner fuel burnout combustion area 6, according to the combustion and air supply conditions of the fuel in the calciner. The hot flue gas in the kiln from the rotary kiln 18 is depleted of oxygen and gas. In the calciner adopting fuel staged combustion technology, the cone 3 at the bottom of the calciner or the denitrification reduction combustion chamber 2 set above the ascending flue 1 of the kiln tail smoke chamber utilizes the oxygen-depleted gas in the kiln from the rotary kiln 18 as the combustion-supporting air. 0-80% of the fuel in the calciner is reburned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com