Carbon fiber tooling arm for robot

A carbon fiber and end picker technology, applied in the field of transmission parts for robots, can solve the problems of restricting the flexibility, accuracy, energy consumption index and service life of robots, insufficient rigidity of aluminum alloy materials, and fatigue resistance, etc., and achieves a small specific gravity. , strong rigidity, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

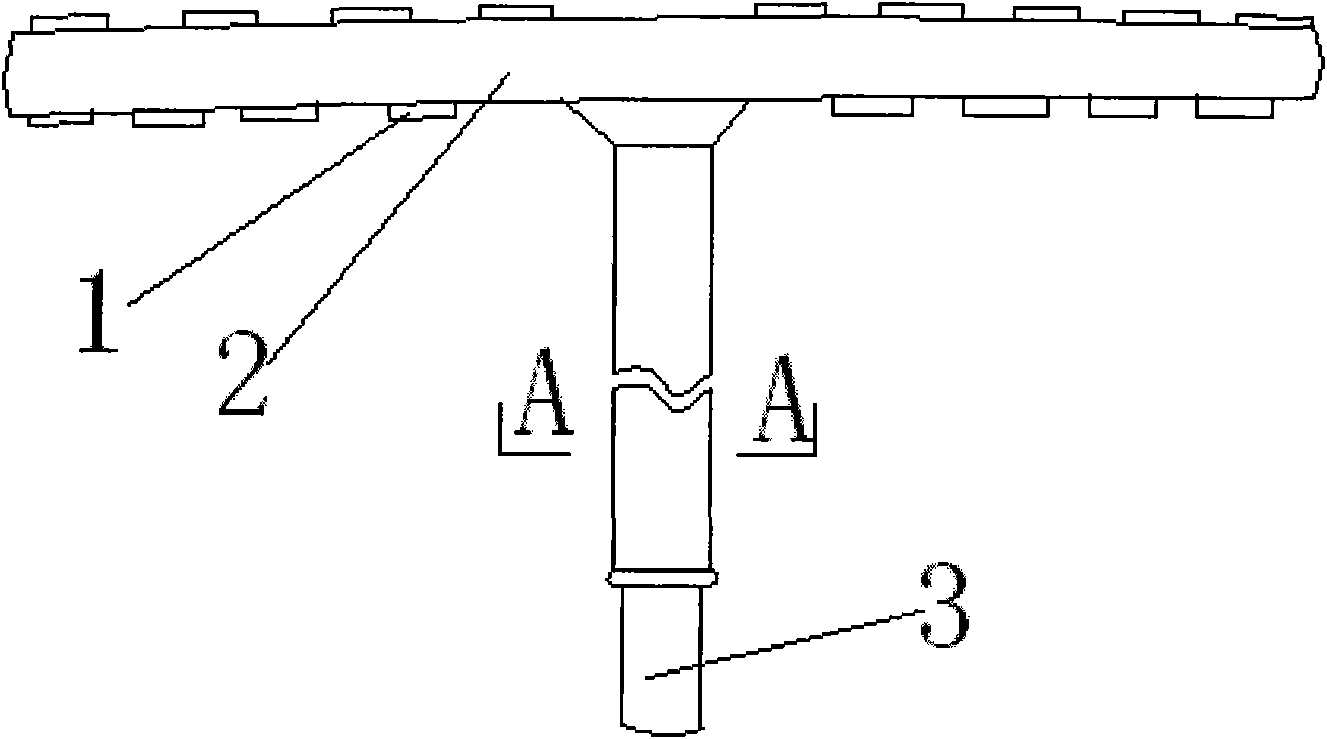

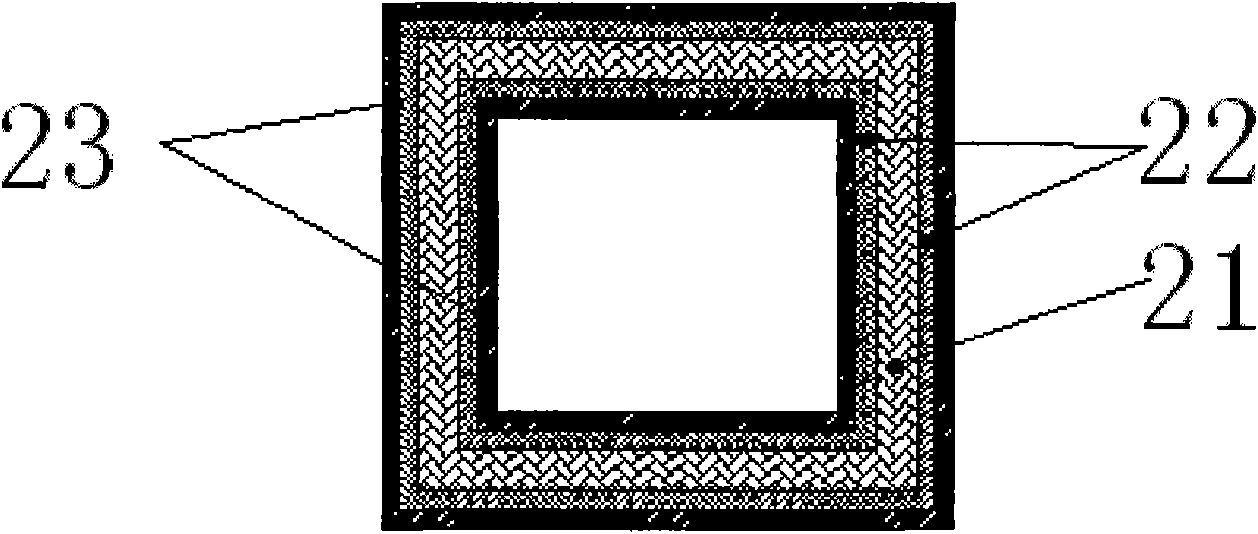

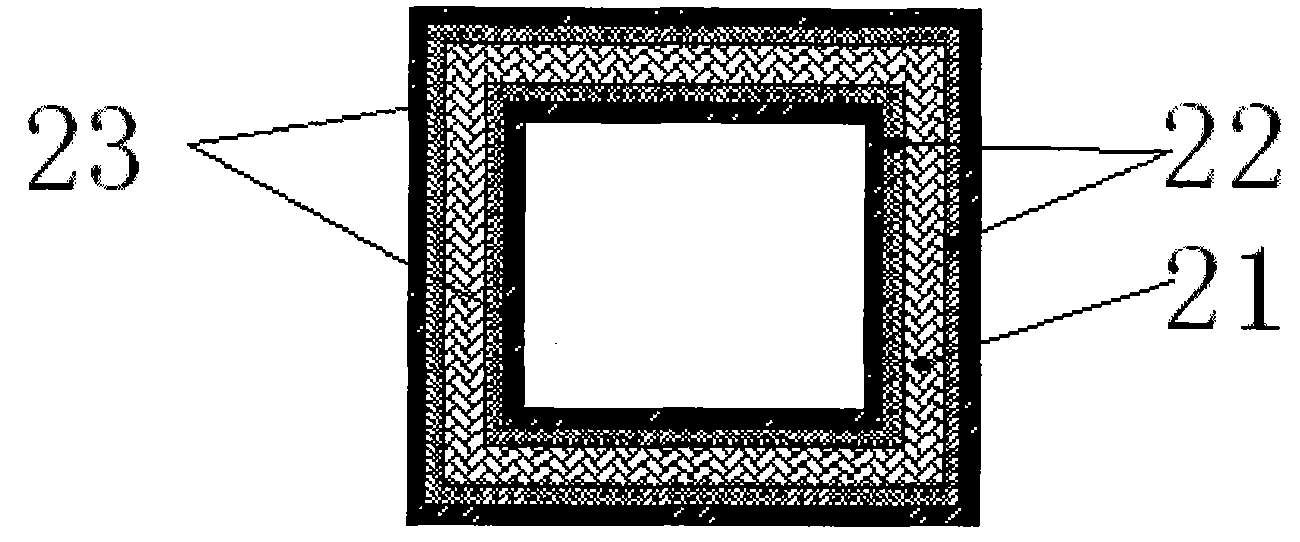

[0010] Referring to the accompanying drawings, the present invention includes a 'T'-shaped body 2, a mounting piece 1, a fixed end 3, the mounting piece 1 is installed on the cross bar of the 'T'-shaped body 2, and the vertical bar end of the 'T'-shaped body is mounted. There is a fixed end 3, which is characterized in that: the 'T'-shaped body 2 is a hollow square column, the inner layer of the column wall is carbon fiber woven cloth 21, the outer layer is continuous carbon fiber 22, and the whole is impregnated and cured by epoxy resin 23.

[0011] The so-called hollow square column shape means that its cross-sectional shape is square outside, the four walls are solid, and the inside is hollow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com