Dolomite calcination heat-recovering method and system

A waste heat recovery and dolomite technology, applied in the field of dolomite calcination, can solve the problems of high energy consumption, environmental pollution, waste heat of dolomite in the calcining rotary kiln combustion system, avoid natural loss, improve working environment, and reduce fuel consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

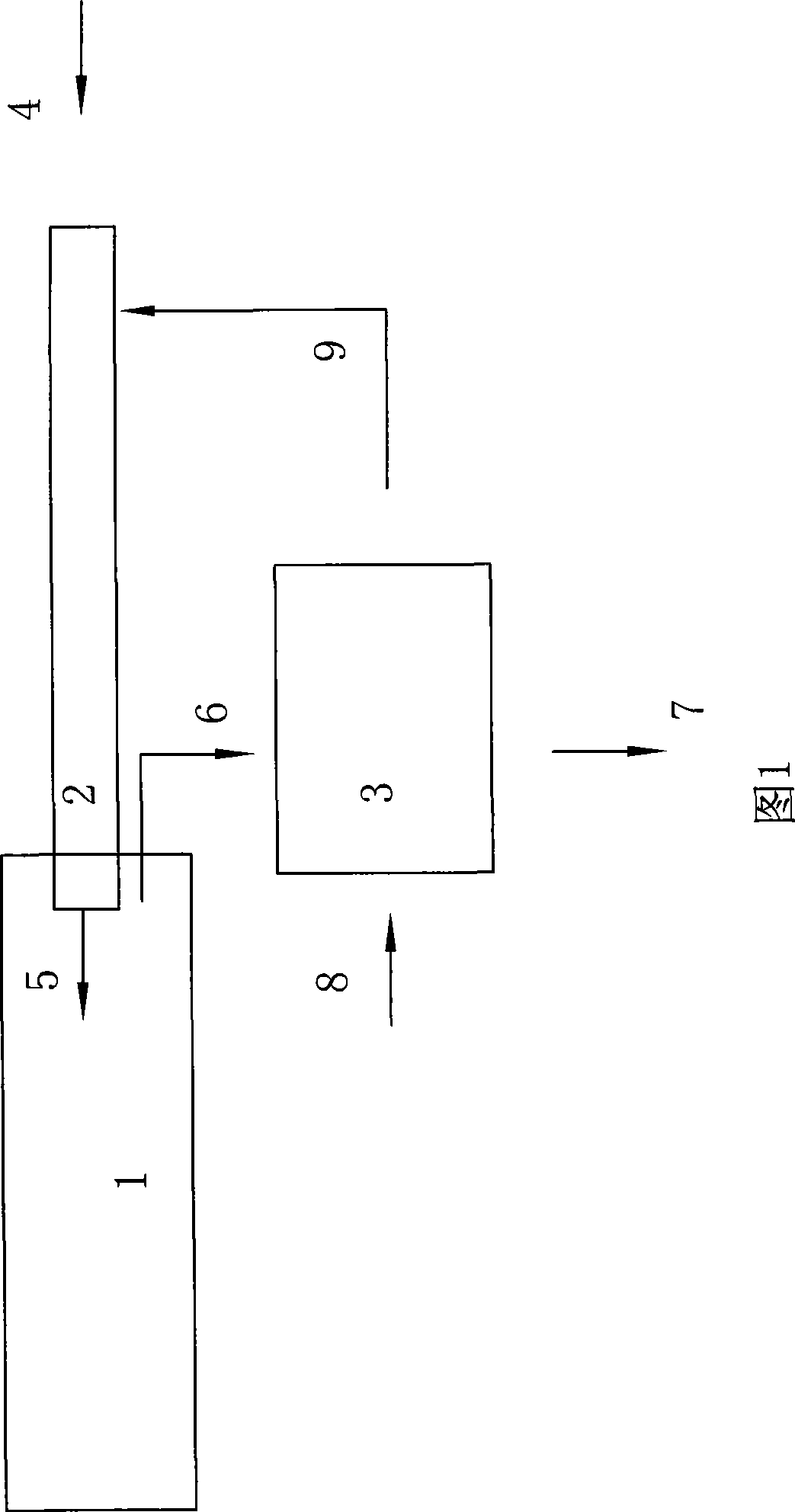

[0021] A dolomite calcining waste heat recovery method of the present invention comprises the following steps: making the material in the dolomite rotary kiln 1 rotate with the kiln body, and sending the high-temperature combustion gas 5 produced by the combustion system 2 of the rotary kiln combustion fuel 4 into the dolomite rotary kiln In the kiln 1, the high-temperature combustion gas 5 is sent into the dolomite rotary kiln 1 against the direction of material movement; the calcined dolomite 6 enters the heat exchange equipment 3 through the kiln head launder, and at the same time, the cold air 8 passes through the general fan during the heat exchange process. Continuously sent to the heat exchange equipment 3, the cold air 8 is evenly passed through the gap of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com