Sterilizing technology used for sterile filling production line

An aseptic filling and production line technology, applied in packaging, bottling machines, bottle filling, etc., can solve the problems of high consumption of pure water and energy, poor cooling effect, etc., to reduce operating input costs, and achieve good heat recovery and cooling ability. , the effect of low operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

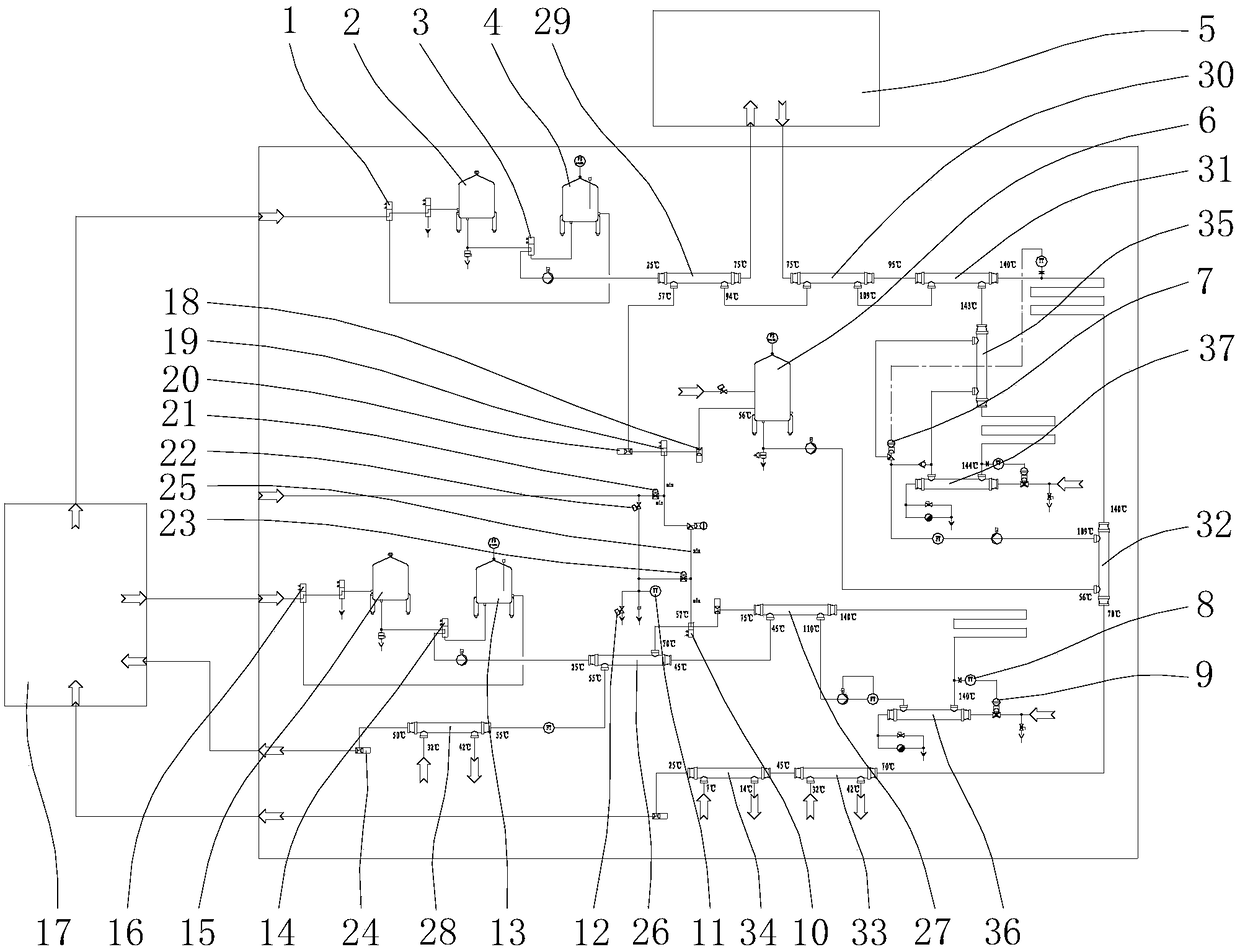

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] see figure 1 As shown, in order to combine the material sterilizer and the sterile water sterilizer into an integrated machine, a first pipeline 25 is added between the high-temperature hot water circulation system and the sterile water circulation system.

[0026] Before work:

[0027] First, perform SIP cleaning on the aseptic water circulation system, the water supply is provided by the aseptic water SIP tank 13, and the aseptic water passes through the first heat exchanger 26, the second heat exchanger 27, the first steam heat exchanger 36, and then flows back through The second heat exchanger 27 , the first heat exchanger 26 , the third heat exchanger 28 , and the aseptic filling machine 17 return to the aseptic water SIP tank 13 . The first heat exchanger 26 and the second heat exchanger 27 are used to exchange heat between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com