Device and method of recycling C2 from refinery dry gas

A refinery dry gas and concentrated gas technology, applied in chemical instruments and methods, separation methods, and gas mixture processing, etc. The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

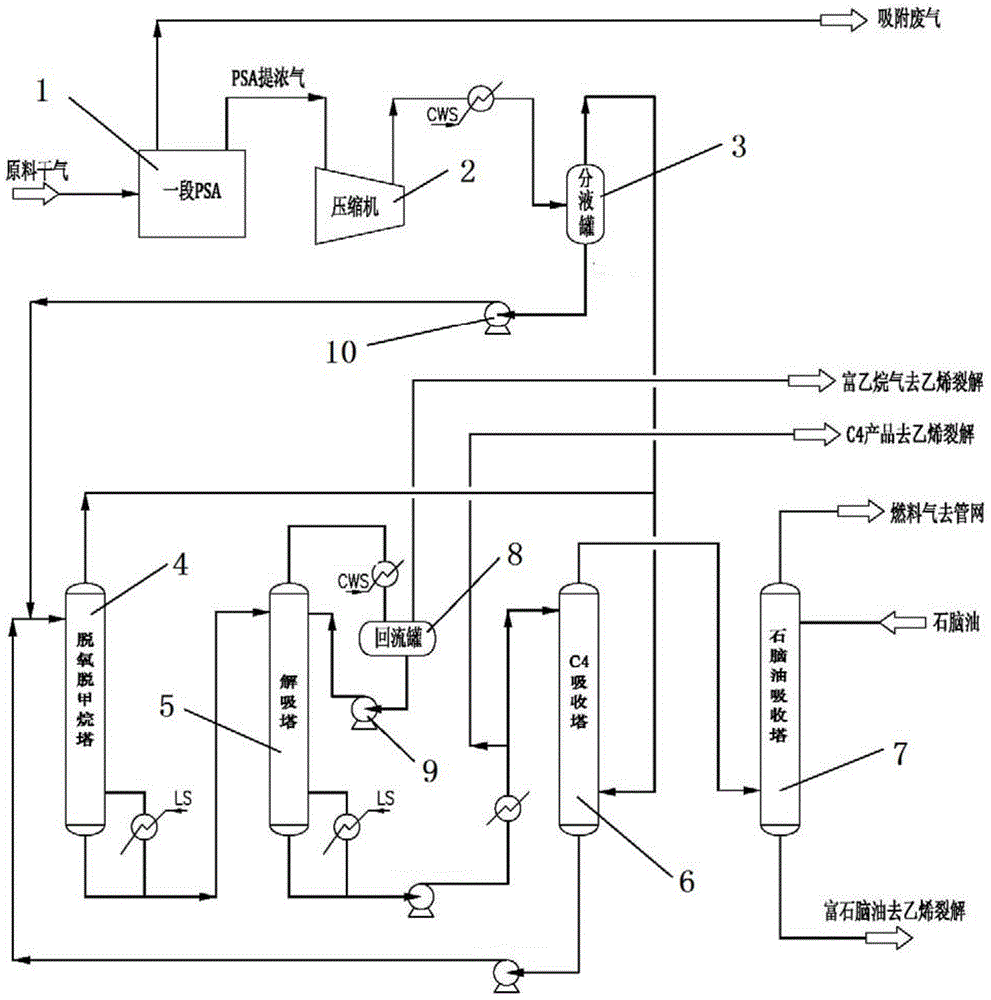

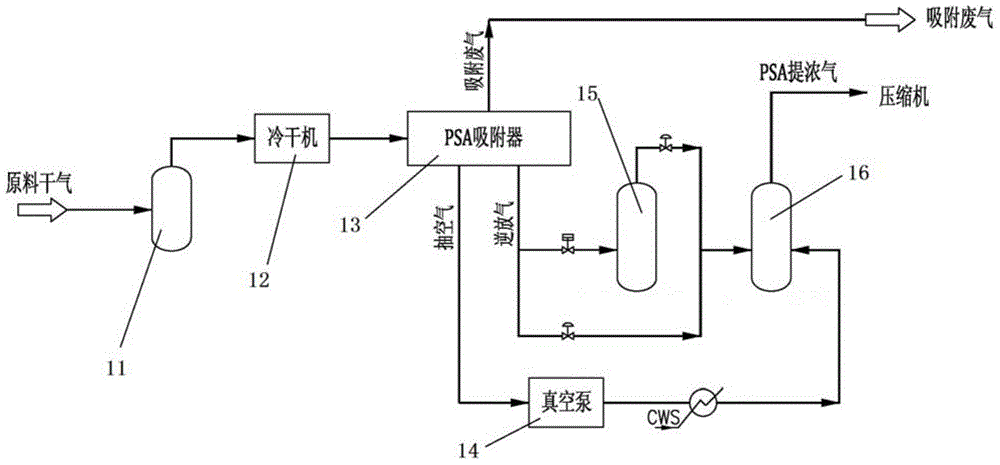

[0033] Such as Figure 1-2 As shown, in this embodiment, a device for recovering C2 in refinery dry gas includes a PSA unit, a compression unit and an oil absorption unit;

[0034] The PSA unit includes a section of PSA device 1, including a raw gas buffer tank 11, a cold dryer 12, a group of PSA adsorbers 13, a vacuum pump 14, a reverse deflation buffer tank 15, a concentrated gas buffer tank 16, and a raw gas buffer tank 11 is connected to the inlet of the cold dryer 12 through a pipeline, and the outlet of the cold dryer 12 is connected to the PSA adsorber 13, and the outlet of the PSA adsorber 13 is connected to the concentrated gas buffer tank 16 through the vacuum pump 14, and the PSA adsorption The reverse deflation branch of the device 13 is connected with the reverse deflation buffer tank 15 and the concentrated gas buffer tank 16 respectively, the outlet of the reverse deflated buffer tank 15 is connected with the concentrated gas buffer tank 16, and the concentrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com