Rotary water film air treatment equipment

An air treatment device and rotating water technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve problems such as inconvenient installation and use, large floor space, and large water consumption. Achieve the effects of less water consumption, compact device structure and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

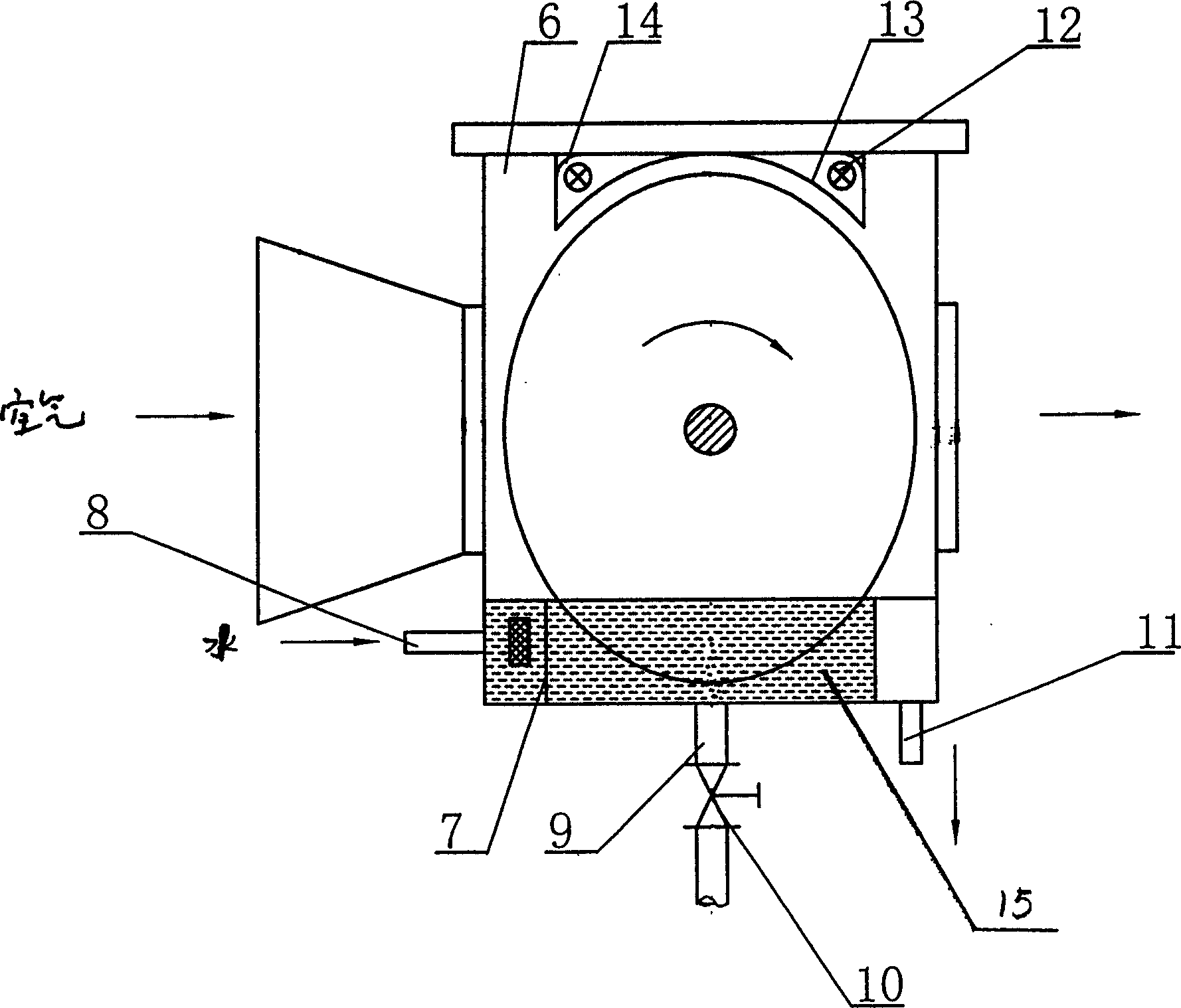

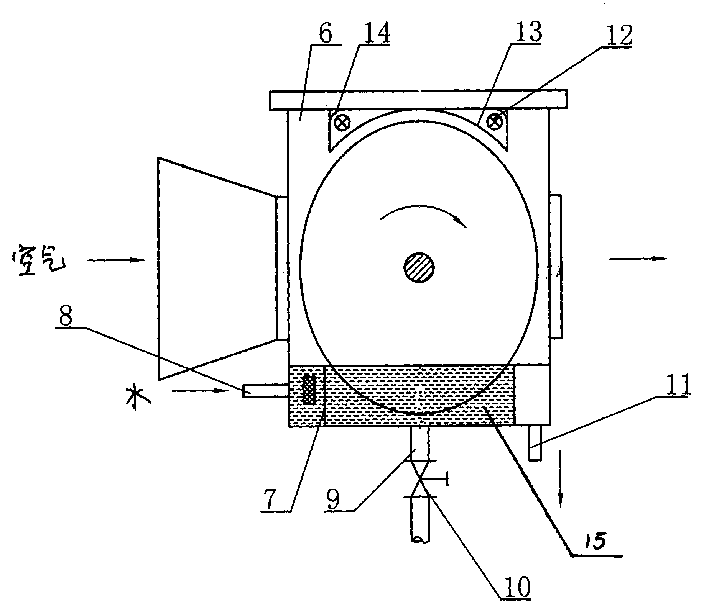

[0008] Accompanying drawing is the specific embodiment of the present invention;

[0009] Below in conjunction with accompanying drawing, technical content of the present invention will be further described:

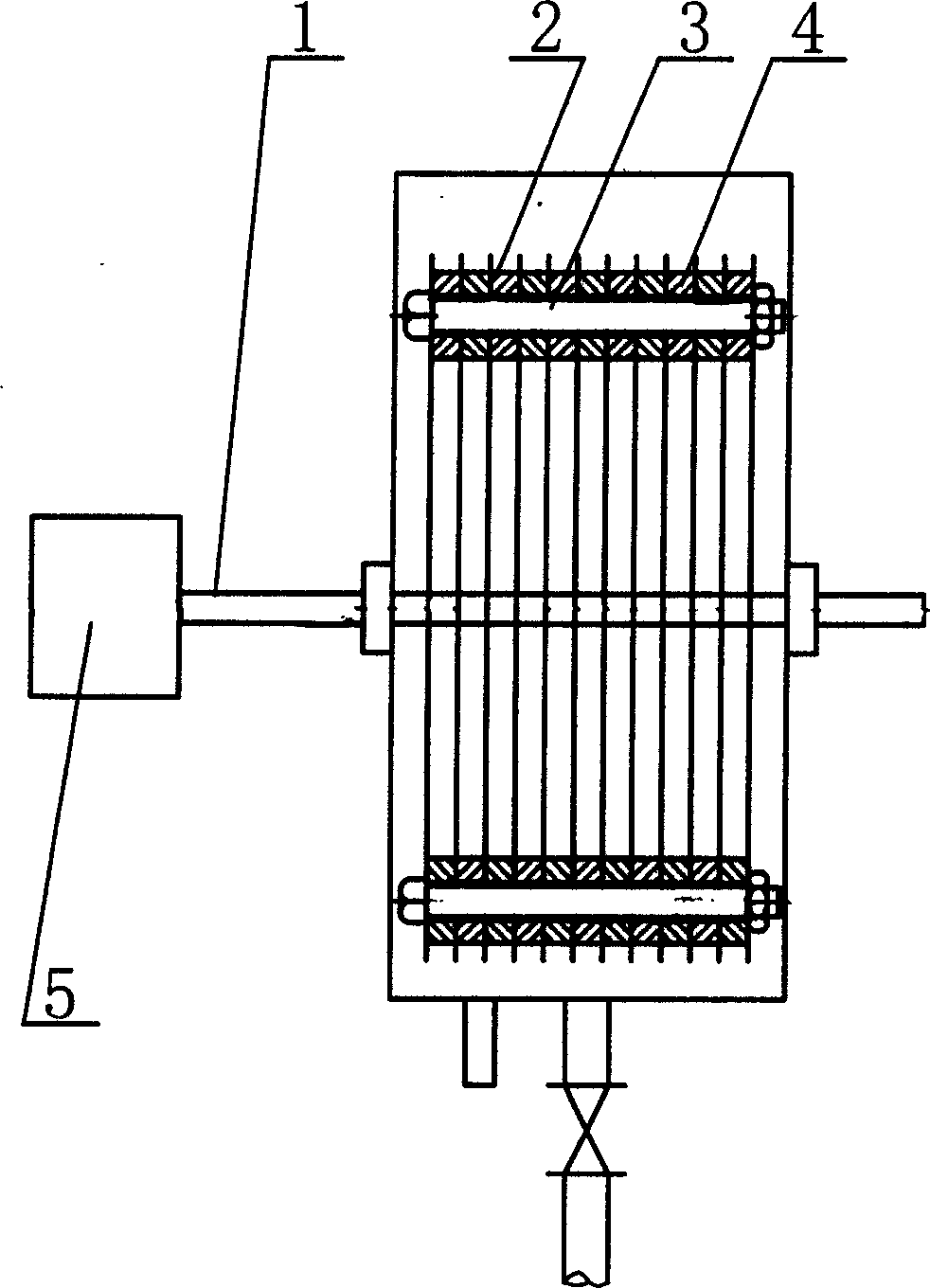

[0010] refer to figure 1 , figure 2 As shown, a rotating water film air treatment device includes a housing 6, a rotatable shaft 1 and a driving device 5, the rotating shaft 1 is directly connected with the driving device 5, and a disc 2 is arranged in the housing 6, Several thin discs 2 whose surfaces are parallel to each other are installed on the rotating shaft 1, and are fixed together with the rotating shaft 1 to form a disc group. A certain gap is maintained between the discs 2 and they are fixed to each other. Ultraviolet lamps 12 are respectively arranged on the top, and the lower part of the housing 6 is also used as a water tank 15. Two partitions 7 are arranged at both ends of the water tank 15, a water inlet 8 is arranged at one end of the water tank 15, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com