Device for extracting pure nitrogen from polluted nitrogen high in extraction rate and low in energy consumption and extracting method thereof

A technology of dirty nitrogen and extraction rate, which is applied to the equipment for purifying nitrogen with high extraction rate and low energy consumption of dirty nitrogen and its extraction field, can solve the problems that the nitrogen output cannot meet the production demand, the nitrogen cannot be produced, the investment cost and the operation cost are high, Achieve the effect of reducing exhaust pressure, reducing energy consumption index, and reducing the temperature of evaporation side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it should not be understood that the scope of the above subject of the present invention is limited to the following embodiments.

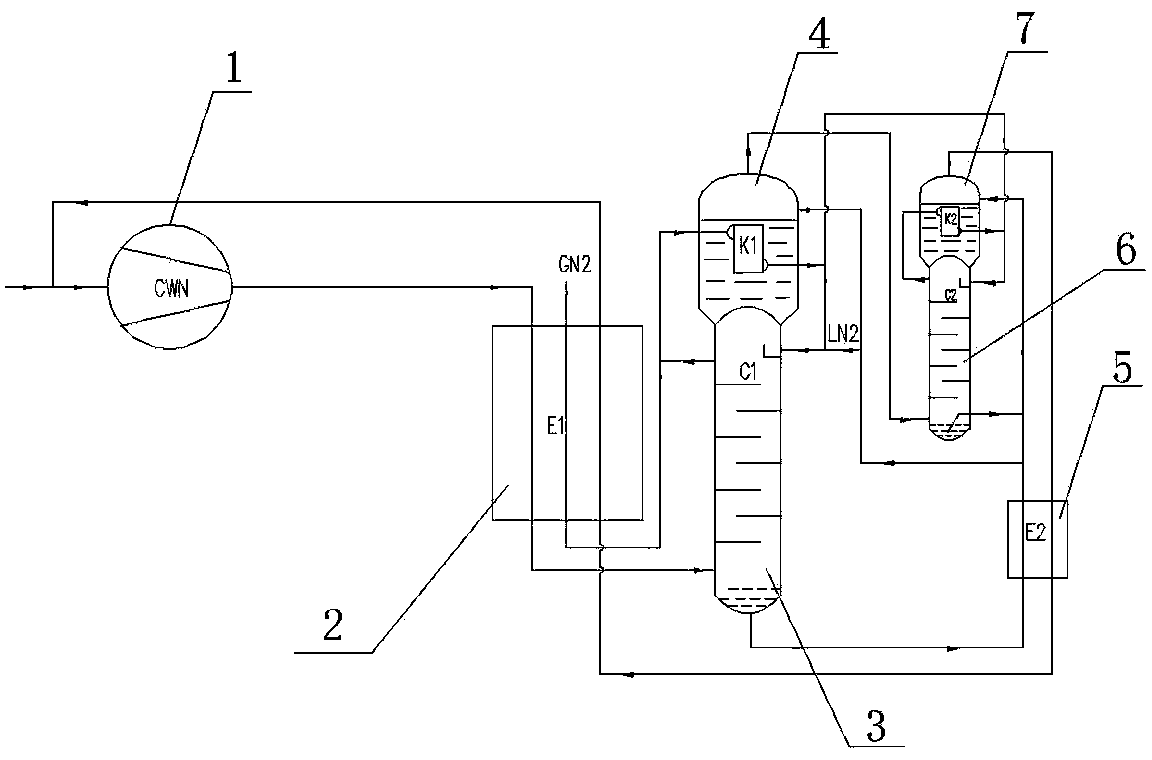

[0019] Such as figure 1 Shown, a kind of equipment of high extraction rate and low energy consumption polluted nitrogen purification nitrogen comprises polluted nitrogen compressor 1, the main heat exchanger 2 that is connected on the polluted nitrogen compressor 1, the main heat exchanger that is connected on the main heat exchanger 2 Tower 3, the auxiliary tower 6 and subcooler 5 that are connected on the main tower 3, the main tower 3 is provided with the main tower condenser 4, the auxiliary tower 6 is provided with the auxiliary tower condenser 7, the sewage of the dirty nitrogen compressor 1 The nitrogen outlet is connected to the dirty nitrogen inlet of the main heat exchanger 2 through a pipeline, the dirty nitrogen out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com