Erosion-resistant kaolin honeycomb ceramic heat accumulating body and preparation method thereof

A technology of honeycomb ceramics and corrosion resistance, which is applied to ceramic products, clay products, and other household appliances to achieve high-efficiency heat storage and release, low equipment wear, and improved service life and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

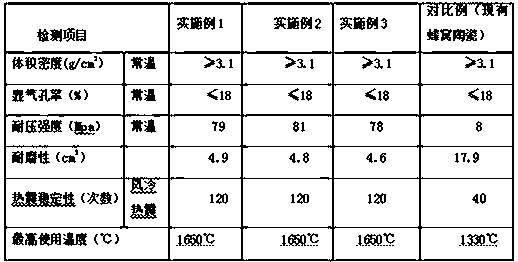

Examples

Embodiment 1

[0022] An erosion-resistant kaolin honeycomb ceramic regenerator mainly consists of the following components: 36 parts of potassium feldspar, 72 parts of kaolin, 6 parts of talc, 10 parts of montmorillonite, 4 parts of glass fiber, and 7 parts of 0.3mm chromium ore powder , 3 parts of aluminate cement, 2 parts of silica powder, 4 parts of chlorinated polyethylene, 3 parts of maleic acid-acrylic acid copolymer, 10 parts of hydroxypropyl methylcellulose, 2 parts of phthalate, mono 2 parts of ethanolamine and 1 part of stearic acid are prepared by kneading mud, stale, extruded, dried and calcined, impregnated with strengthening slurry, dried and calcined again;

[0023] The strengthening slurry is composed of the following components: 7 parts of alumina micropowder, 6 parts of chromium oxide green micropowder, 2 parts of carbon fiber, 5 parts of silicon nitride, 6 parts of cerium nitrate, Al 2 o 3 7 parts, 5 parts of methyl methacrylate-butadiene-styrene terpolymer, 0.8 parts of...

Embodiment 2

[0037] An erosion-resistant kaolin honeycomb ceramic regenerator mainly consists of the following components: 38 parts of potassium feldspar, 75 parts of kaolin, 8 parts of talc, 12 parts of montmorillonite, 5 parts of glass fiber, and 12 parts of 0.7mm chromium ore powder , 3 parts of aluminate cement, 2 parts of silica powder, 4 parts of chlorinated polyethylene, 4 parts of maleic acid-acrylic acid copolymer, 11 parts of hydroxypropyl methylcellulose, 2 parts of phthalate, mono 2 parts of ethanolamine and 2 parts of stearic acid are prepared by kneading mud, aging, extruding, drying and calcining, impregnating the strengthening slurry, drying and calcining again;

[0038] The strengthening slurry is composed of the following components: 8 parts of alumina micropowder, 13 parts of chromium oxide green micropowder, 2 parts of carbon fiber, 5 parts of silicon nitride, 7 parts of cerium nitrate, Al 2 o 3 8 parts, 7 parts of methyl methacrylate-butadiene-styrene terpolymer, 1.5 ...

Embodiment 3

[0052] An erosion-resistant kaolin honeycomb ceramic regenerator mainly consists of the following components: 40 parts of potassium feldspar, 79 parts of kaolin, 9 parts of talc, 15 parts of montmorillonite, 5 parts of glass fiber, 14 parts of 1mm chromium ore powder, 4 parts of aluminate cement, 2 parts of silica powder, 6 parts of chlorinated polyethylene, 4 parts of maleic acid-acrylic acid copolymer, 11 parts of hydroxypropyl methylcellulose, 3 parts of phthalate, monoethanolamine 3 parts and 2 parts of stearic acid are prepared by kneading mud, aging, extruding, drying and calcining, impregnating the strengthening slurry, drying and calcining again;

[0053] The strengthening slurry is composed of the following components: 10 parts of alumina micropowder, 15 parts of chromium oxide green micropowder, 2 parts of carbon fiber, 6 parts of silicon nitride, 7 parts of cerium nitrate, Al 2 o 3 9 parts, 10 parts of methyl methacrylate-butadiene-styrene terpolymer, 2 parts of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com