A symmetrical bubbling plate heat transfer element

A heat transfer element and bubbling technology, applied in the direction of laminated elements, fixed plate conduit assemblies, indirect heat exchangers, etc. Cleaning process, good comprehensive performance, and the effect of enhancing pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

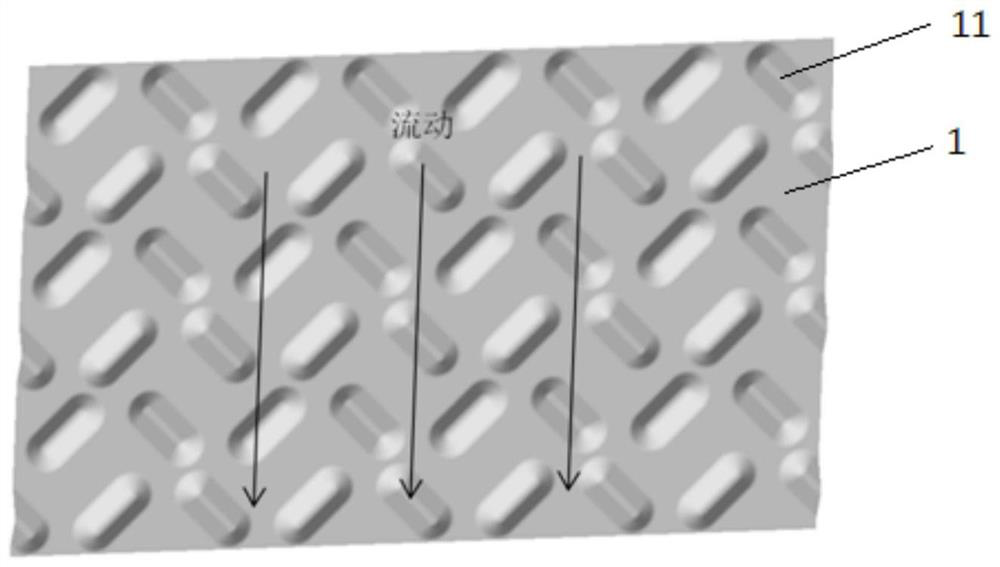

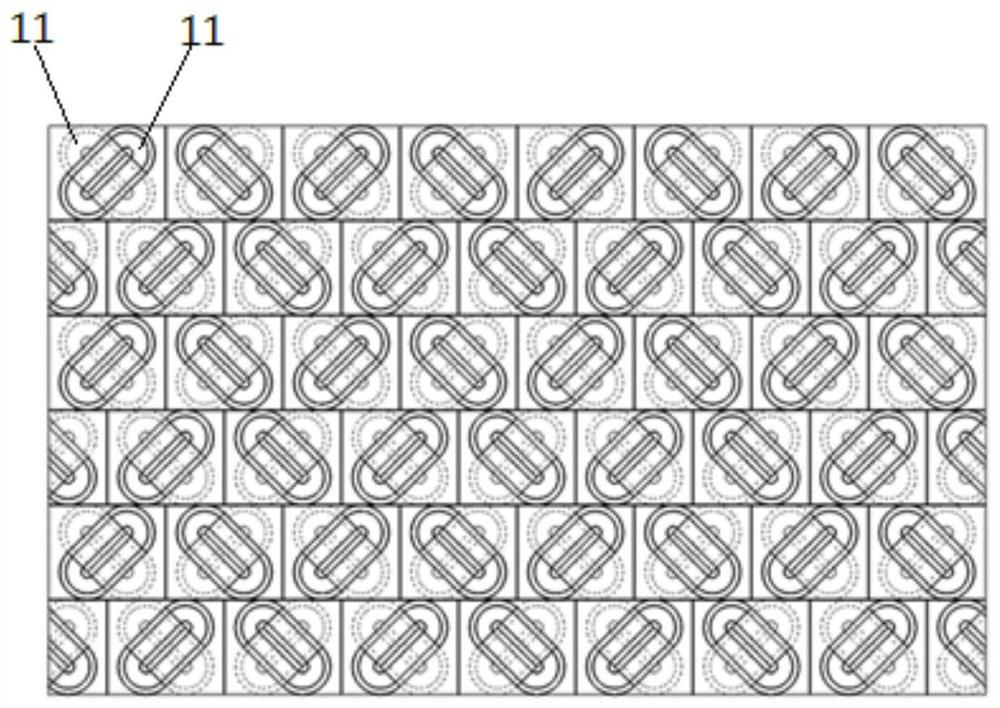

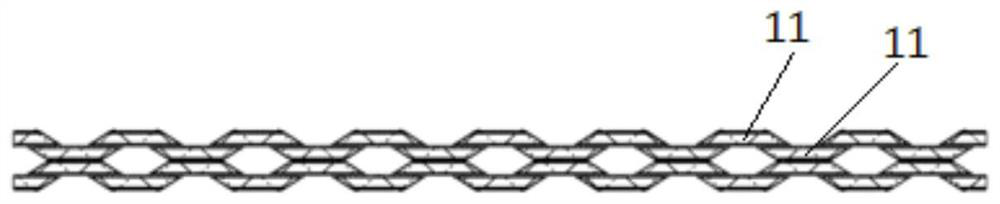

[0029]Seefigure 1 withfigure 2 , A symmetrical bubbling plate heat transfer element, comprising two or more heat exchange plates 1 superimposed on each other. Both sides of the heat exchange plate 1 are pressed with bubbling convex bodies 11, the convex bodies and The angle of the main flow direction of the fluid is 45°, and the adjacent convex bodies on one side of the heat exchange plate are symmetrical. The convex bodies 11 on the adjacent heat exchange plates 1 contact and support each other to form a plate-shaped corrugated channel. The arrangement directions of the mutually contacting convex bodies are perpendicular to each other. The adjacent convex bodies 11 on one side of the same heat exchange plate 1 form a direct fluid flow. Area. . Further, the protrusions 11 have the same size.

[0030]Further, the length of the convex body 11 is 10-30 mm, the width of the convex body 11 is 5-20 mm, and the height of the convex body 11 is 1-5 mm.

[0031]Further, the distance between adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com