Sebacic acid molten atomizing granulating technology and device thereof

A technology of melt granulation and sebacic acid, which is applied in the direction of liquid separation into bead droplets and granulation, can solve the problems of unsatisfactory technical indicators, reduction of energy consumption, and failure to fully consider the particularity of physical indicators of molten sebacic acid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

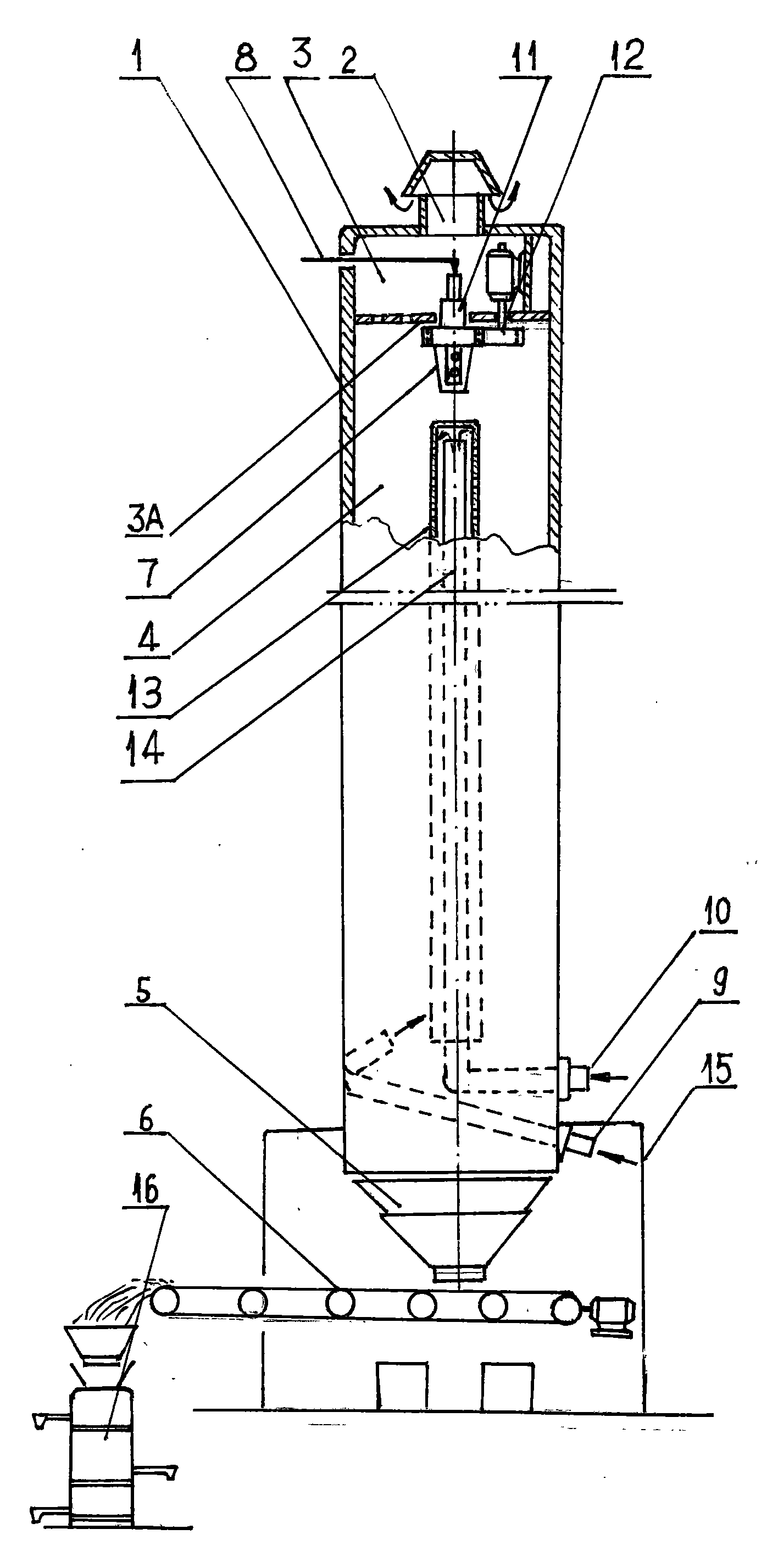

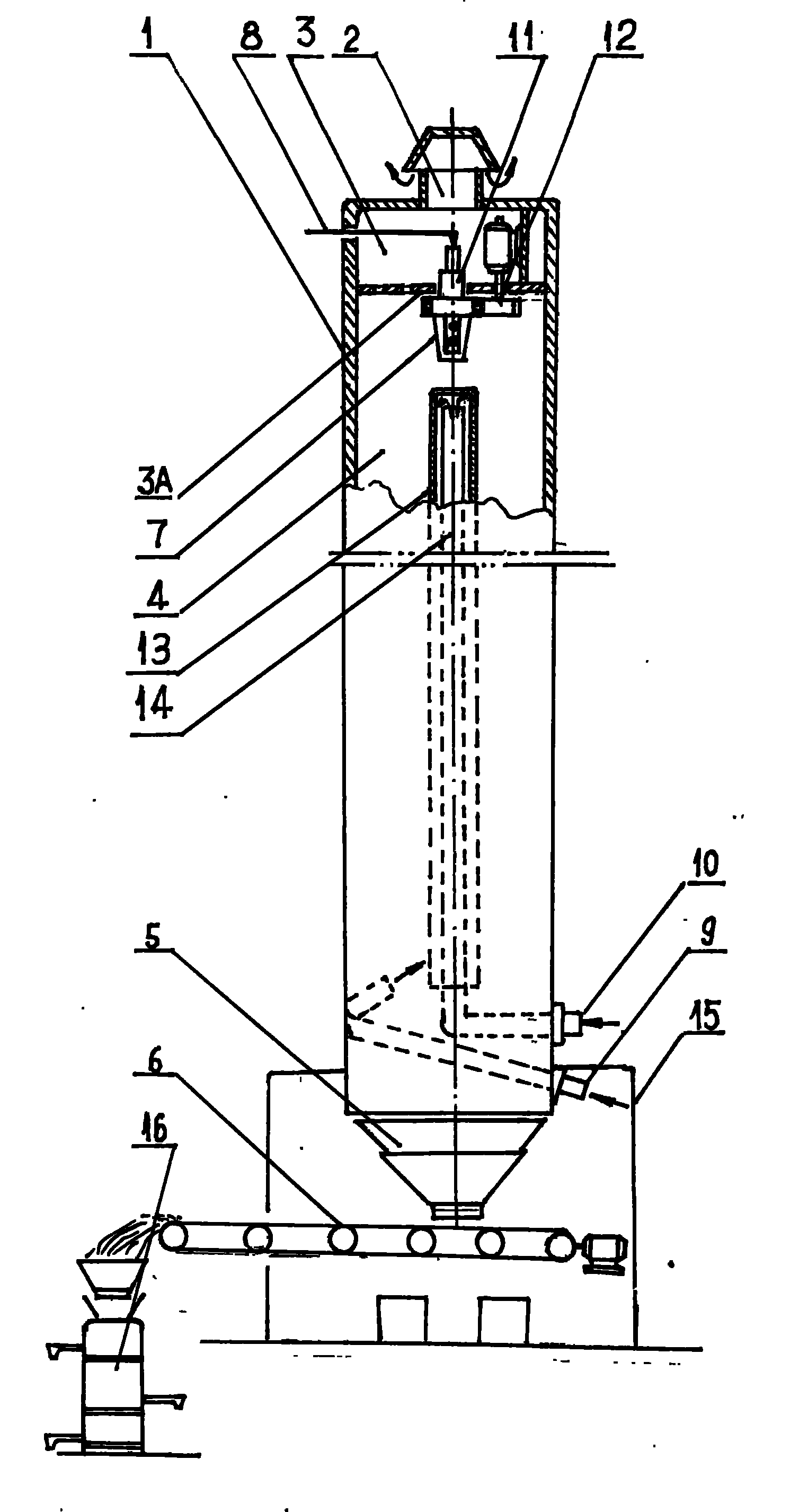

[0018] Can have a further understanding of the process of the present invention with reference to the accompanying drawings. In this process, saturated steam is used as the processing heat source of industrial sebacic acid products, and the redesigned process is realized by the following procedures;

[0019] ①Choose qualified industrial sebacic acid products and add them to a melting tank with stirring, and pass saturated steam into the melting tank to heat and melt sebacic acid,

[0020] ② The sebacic acid that is stirred uniformly after melting is transported to the centrifugal chamber 7 of the centrifugal sprayer by means of the heat preservation pipeline 8,

[0021] ③The molten sebacic acid is atomized and sprayed out by means of the evenly distributed injection holes on the side wall of the centrifugal chamber and the high-speed rotating centrifugal chamber,

[0022] ④Introduce the atomized molten sebacic acid into the countercurrent settling tower, and complete cooling,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com