Anti-erosion gunning mix

A gunning material and anti-erosion technology, which is applied in the field of unshaped refractory materials, can solve the problems of low high-temperature strength, gunning accumulation and shedding, and poor corrosion resistance of gunning materials, and achieve strong bonding strength, reduce fluidity, increase Effect of Drying and Burnt Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

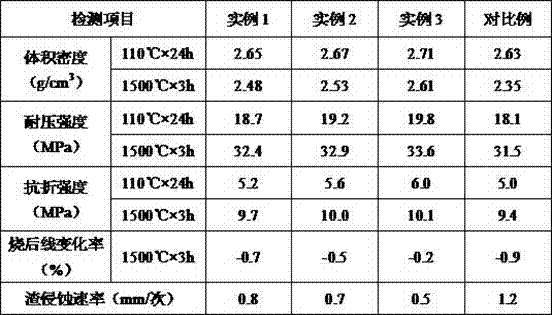

Examples

example 1

[0024] In parts by weight, take 70 parts of clay, 10 parts of glass fiber, 20 parts of sericite, 40 parts of quartz stone and 40 parts of attapulgite, add them into a grinder and grind them, and pass through a 220 mesh sieve to obtain a mixed powder. 1:5, add acrylic acid dropwise to 5% sodium hydroxide solution by mass fraction, stir and mix to obtain a neutralizing liquid, and mix the mixed powder and neutralizing liquid at a mass ratio of 1:10, then add 1% neutralizing liquid Sodium dodecylbenzenesulfonate, and transferred to a high-speed disperser, stirred and mixed at a speed of 2000r / min for 15min, after stirring, an emulsified mixed solution was obtained, and the emulsified mixed solution was added to the reactor, and added to the reactor in turn The mass of the emulsified mixed liquid is 0.3% Tween-80, the mass of the emulsified mixed liquid is 0.8% ammonium persulfate, and the mass of the emulsified mixed liquid is 1% N,N-methylenebisacrylamide, heated to 60°C, stirred...

example 2

[0026] In parts by weight, take 75 parts of clay, 13 parts of glass fiber, 30 parts of sericite, 45 parts of quartz stone and 50 parts of attapulgite, add them into a grinder and grind them, and pass through a 230-mesh sieve to obtain a mixed powder. 1:5, add acrylic acid dropwise to 5% sodium hydroxide solution by mass fraction, stir and mix to obtain a neutralizing liquid, and mix the mixed powder and neutralizing liquid at a mass ratio of 1:10, then add 2% neutralizing liquid Sodium dodecylbenzenesulfonate, and transferred to a high-speed disperser, stirred and mixed at a speed of 2250r / min for 18min, after stirring, an emulsified mixed solution was obtained, and the emulsified mixed solution was added to the reactor, and added to the reactor in turn The mass of the emulsified mixed liquid is 0.4% Tween-80, the mass of the emulsified mixed liquid is 0.9% ammonium persulfate, and the mass of the emulsified mixed liquid is 1% N,N-methylenebisacrylamide, heated to 65°C, stirred...

example 3

[0028]In parts by weight, take 80 parts of clay, 15 parts of glass fiber, 40 parts of sericite, 50 parts of quartz stone and 60 parts of attapulgite, add them into a grinder and grind them, and pass through a 240-mesh sieve to obtain a mixed powder. 1:5, add acrylic acid dropwise to 5% sodium hydroxide solution by mass fraction, stir and mix to obtain a neutralizing liquid, and mix the mixed powder and neutralizing liquid at a mass ratio of 1:10, then add 3% neutralizing liquid Sodium dodecylbenzenesulfonate, and transferred to a high-speed disperser, stirred and mixed at a speed of 2500r / min for 20min, after stirring, an emulsified mixed solution was obtained, and the emulsified mixed solution was added to the reactor, and added to the reactor in turn The mass of the emulsified mixed liquid is 0.5% Tween-80, the mass of the emulsified mixed liquid is 1.0% ammonium persulfate, and the mass of the emulsified mixed liquid is 2% N,N-methylenebisacrylamide, heated to 70°C, stirred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com