High-property spraying paint for slag pot and preparation method of high-property spraying paint

A high-performance coating technology, applied in the field of refractory unshaped refractory products, can solve the problems of manual cleaning, adhesion, high cost, etc., and achieve the effect of increased tank return rate, small rebound rate, and improved tank life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

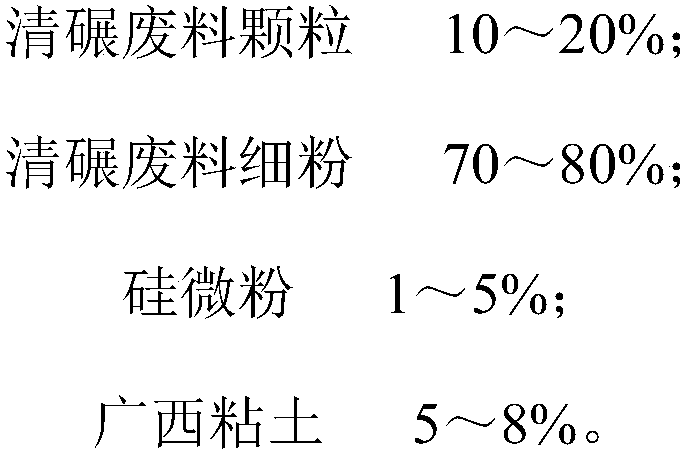

[0030] A high-performance slag tank spray paint, including main ingredients and additives. The raw materials and weight percentages of the main ingredients are shown in Table 2. The admixtures include carboxymethyl cellulose, sodium tripolyphosphate and bentonite, and the percentages by weight of the main ingredients are respectively 0.3% of carboxymethyl cellulose, 0.2% of sodium tripolyphosphate and 0.5% of bentonite.

[0031] Table 2

[0032] raw material name

Cleaning waste pellets

Cleaning waste fine powder

Silica powder

Guangxi clay

0.5-0mm

180 mesh

180 mesh

weight percentage (%)

20

70

3

7

al 2 o 3 +MgO≥80%, graphite≥9%

al 2 o 3 +MgO≥80%, graphite≥9%

SiO 2 ≥90%

al 2 o 3 ≥32%

[0033] The preparation method of the high-performance slag tank spray coating is:

[0034] (1) Mix milling waste fine powder, silicon m...

Embodiment 2

[0042] A high-performance slag tank spray paint, including main ingredients and additives. The raw materials and weight percentages of the main ingredients are shown in Table 4. The admixture comprises methyl cellulose, sodium hexametaphosphate, and lignosulfonate, and the percentages by weight of the main ingredients are respectively 0.5% of methyl cellulose, 0.5% of sodium hexametaphosphate, and 1.0% of lignosulfonate.

[0043] Table 4

[0044] raw material name

Cleaning waste pellets

Cleaning waste fine powder

Silica powder

Guangxi clay

0.5-0mm

180 mesh

180 mesh

weight percentage (%)

10

80

5

5

Al 2 o 3 +MgO≥80%, graphite≥9%

al 2 o 3 +MgO≥80%, graphite≥9%

SiO 2 ≥90%

al 2 o 3 ≥32%

[0045] The preparation method of the high-performance slag tank spray coating is:

[0046] (1) Mix milling waste fine powder, silicon ...

Embodiment 3

[0054] A high-performance slag tank spray paint, including main ingredients and additives. The raw materials and weight percentages of the main ingredients are shown in Table 6. The admixture comprises carboxymethyl cellulose, sodium tripolyphosphate, sodium hexametaphosphate, lignosulfonate, bentonite, and its weight percentages of main ingredients are respectively 0.1 of carboxymethyl cellulose, 0.2 of sodium tripolyphosphate, Sodium hexametaphosphate 0.1, lignosulfonate 0.4, bentonite 0.1.

[0055] Table 6

[0056] raw material name

Cleaning waste pellets

Cleaning waste fine powder

Silica powder

Guangxi clay

0.5-0mm

180 mesh

180 mesh

weight percentage (%)

15

75

4

6

al 2 o 3 +MgO≥80%, graphite≥9%

Al 2 o 3 +MgO≥80%, graphite≥9%

SiO 2 ≥90%

Al 2 o 3 ≥32%

[0057] The preparation method of the high-performance slag ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com