Production process of unfired alumina-magnesia carbon brick for electric furnace steel ladle

An aluminum-magnesium-carbon brick and production process technology, applied in the field of refractory materials, can solve the problems of reduced service life of ladles, affecting the smooth progress of continuous casting, and harsh conditions of use of ladles, so as to reduce usage, maintain volume stability, and reduce production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Aluminum-magnesium-carbon recycled material 20%, fused corundum 51.2%, fused magnesia-aluminum spinel 10%, fused magnesia 7%, flake graphite 7%, activated alumina micropowder 1%, metal aluminum powder 1%, phenolic Resin 2.8%;

[0027] The recycled alumina-magnesia-carbon bricks are sorted, crushed, magnetically separated to remove iron and cleaned, hydrated and fake particles are processed, and finally made into feed particles;

[0028] Add aluminum-magnesium-carbon brick particles, corundum, fused magnesia, aluminum-magnesium spinel, aluminum powder, flake graphite and phenolic resin into the sand mixer according to the weight ratio for mixing;

[0029] PLC electric program-controlled screw press is used to press and shape the kneaded material, and then send it to a drying furnace at a temperature of 180-220°C for 10-12 hours to obtain finished alumina-magnesia-carbon bricks.

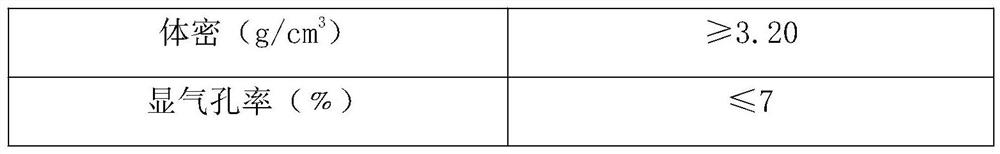

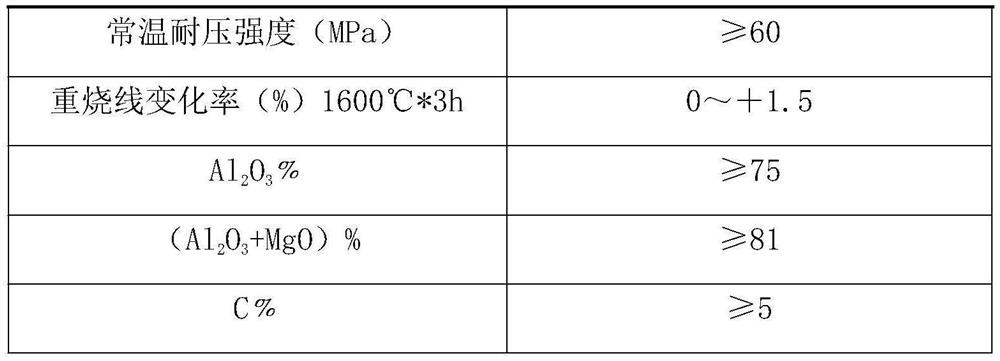

[0030] After testing, the physical and chemical indicators of the finished unfired alumina-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com