Preparation method of carbon/carbon composite material

A carbon composite material and carbon fiber technology, which is applied in the field of carbon/carbon composite material preparation, can solve the problems of difficulty in popularizing and using carbon/carbon composite materials, high energy consumption of the preparation process, and complicated process, so as to shorten the production cycle and reduce the reaction The effect of temperature and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Put the carbon fiber reinforcement (polyacrylonitrile-based carbon fiber) into the container first, and then put 800g of coal tar and AlCl 3 The catalyst (the mass ratio of catalyst to coal tar is 0.05) is mixed evenly, put into the container and placed in an autoclave, and after vacuuming for 30 minutes, the temperature is raised to 190°C, and then nitrogen is filled into the autoclave, and the nitrogen pressure is 4MPa. After 2 hours, the temperature was further raised to 400° C. and maintained at this temperature for 3 hours. Cool naturally to normal temperature after reaction finishes, open still and obtain carbon / carbon composite material (density is 1.34g / cm 3 );

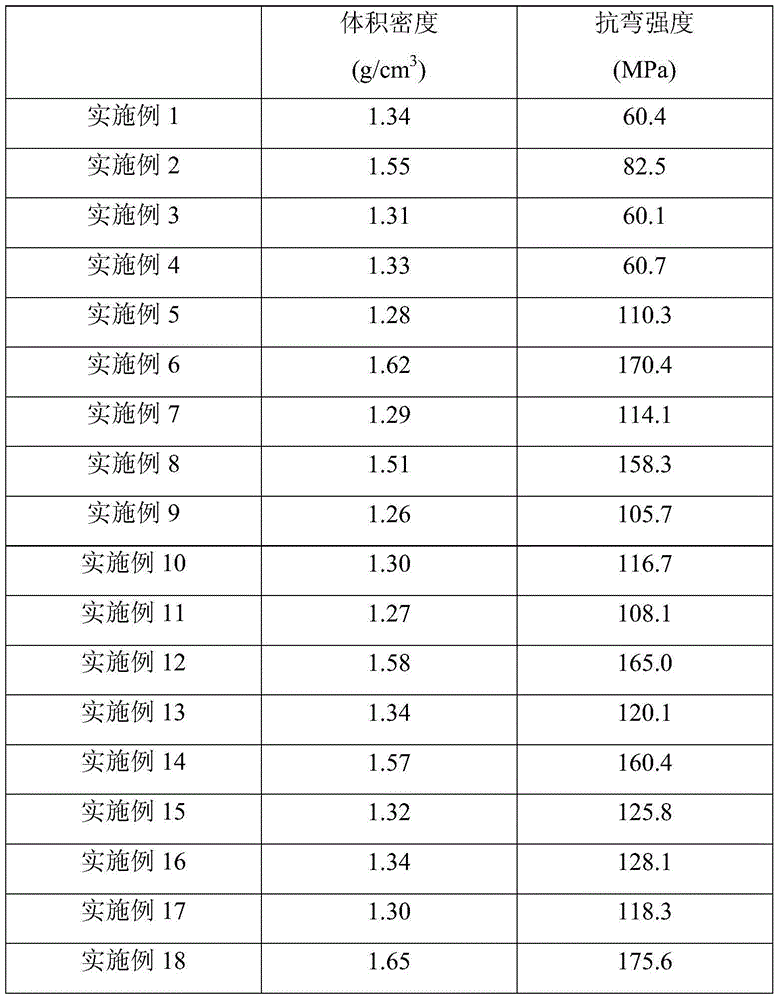

[0020] The specific test data are shown in Table 1.

Embodiment 2

[0022] (1) Put the carbon fiber reinforced body into the container first, then put 800g of coal tar and AlCl 3 The catalyst (the mass ratio of catalyst to coal tar is 0.05) is mixed evenly, put into the container and placed in an autoclave, and after vacuuming for 30 minutes, the temperature is raised to 190°C, and then nitrogen is filled into the autoclave, and the nitrogen pressure is 4MPa. After 2 hours, the temperature was further raised to 400° C. and maintained at this temperature for 3 hours. Cool naturally to normal temperature after reaction finishes, open still and obtain carbon / carbon composite material (density is 1.34g / cm 3 );

[0023] (2) In order to further increase the density of the carbon / carbon composite material, the carbon / carbon composite material obtained in step (1) is densified for the second time according to step (1), and a higher density carbon / carbon composite material can be obtained Material (density 1.55g / cm 3 );

[0024] The specific test d...

Embodiment 3

[0026] (1) Put the carbon fiber reinforced body into the container first, then put 500g of coal tar and AlCl 3 The catalyst (the mass ratio of catalyst to coal tar is 0.02) is mixed evenly, put into the container and placed in an autoclave, and after vacuuming for 30 minutes, the temperature is raised to 190°C, and then nitrogen is filled into the autoclave at a nitrogen pressure of 4 MPa. After 2 hours, the temperature was further raised to 420° C. and maintained at this temperature for 4 hours. Cool naturally to normal temperature after reaction finishes, open still and obtain carbon / carbon composite material (density is 1.31g / cm 3 );

[0027] The specific test data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com