Method for preparing porous ceramic green body by combining microemulsion with freeze drying

A technology of porous ceramics and microemulsions, which is applied in the field of preparation of porous ceramics by combining oil-in-water emulsions with freeze-drying, and microemulsions combined with freeze-drying to prepare porous ceramic bodies. Problems such as the mechanical properties of ceramic products, to achieve the effect of microstructure and mechanical properties regulation, inhibition of ice crystal growth, effective microstructure and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

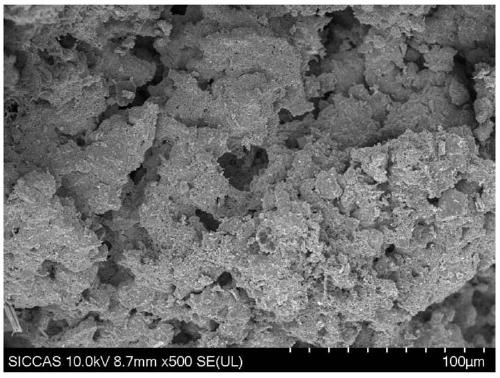

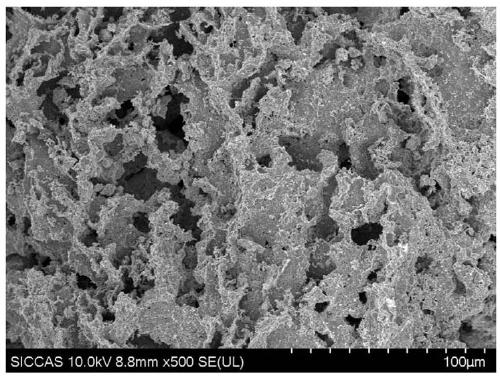

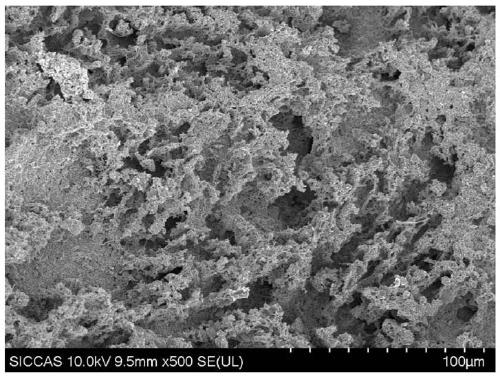

Image

Examples

preparation example Construction

[0036] Preparation of oil-in-water emulsions. Water, cyclohexane, and Tween 80 were stirred to form an oil-in-water emulsion. Among them, cyclohexane exists as an oil phase, but it can also be selected from n-octane, diphenylmethane, cyclopentane and the like. Tween 80 exists as a surfactant, but it can also be selected from sodium dodecylbenzene sulfate, polyoxyethylene sorbitan stearate, polyoxyethylene sorbitan monolaurate, and the like. Wherein, the volume ratio of water and oil phase may be 1:(0.05-0.8), more preferably 1:(0.05-0.5), more preferably 1:(0.05-0.4). If the oil phase is excessive, the ceramic green body is prone to microcracks.

[0037] The ceramic powder and the sintering aid for the ceramic powder are added into the oil-in-water emulsion, and a uniformly mixed ceramic slurry is obtained after ball milling. In the slurry, the recommended amount of the oil phase (for example, cyclohexane) can be 5-40 wt% of the ceramic powder. The amount of water added is...

Embodiment 1

[0048] (1) The water of 56.4g is stirred and mixed with the water-soluble polyvinyl alcohol of 3.6g to form an aqueous solution;

[0049] (2) Transfer the above aqueous solution to a ball mill jar, then add 170g of zirconia balls, 7.7g cyclohexane (density 0.78g / ml), 2.3g Tween 80, 1g ammonium polyacrylate and 100g yttrium oxide to the ball mill jar Stabilized zirconia powder (YSZ, yttrium oxide content is 8mol%), ball mill speed is 300r / min, after ball milling for 2.5 hours, a uniformly mixed water-based slurry is obtained;

[0050] (3) The slurry is vacuum degassed, then injected into a metal mold, and then the mold is transferred to a cold source at -18°C, and frozen for 6 hours to obtain a solidified green body;

[0051] (4) Transfer the molded ceramic body to a freeze dryer, the freeze drying conditions are vacuum degree 5Pa, condensation chamber -68°C, heating plate 60°C, and dry for 48 hours;

[0052] (5) Raise the ceramic body to 600°C at 2°C / min under air conditions,...

Embodiment 2

[0056] (1) The water of 56.4g is stirred and mixed with the water-soluble polyvinyl alcohol of 3.6g to form an aqueous solution;

[0057] (2) Transfer the above-mentioned aqueous solution to a ball mill jar, then add 180g of zirconia balls, 15.4g of cyclohexane, 4.6g of Tween 80, 1g of ammonium polyacrylate and 100g of yttria stabilized zirconia powder (YSZ) to the ball mill , the rotating speed of the ball mill is 300r / min, and the uniformly mixed water-based slurry is obtained after ball milling for 2.5 hours;

[0058] (3) The slurry is vacuum degassed, then injected into a metal mold, and then the mold is transferred to a cold source at -18°C, and frozen for 6 hours to obtain a solidified green body;

[0059] (4) Transfer the molded ceramic body to a freeze dryer, the freeze drying conditions are vacuum degree 5Pa, condensation chamber -68°C, heating plate 60°C, and dry for 48 hours;

[0060] (5) Raise the ceramic body to 600°C at 2°C / min under air conditions, keep it warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com