Ansa-metallocene compound and method for preparing supported catalyst using same

A metallocene compound, compound technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as unsatisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] In addition, in addition to the above-mentioned steps, any generally performed steps in the art may be further included before or after each step, and the production method of the present invention is not limited to the above-mentioned steps.

[0074] Meanwhile, according to another embodiment of the present invention, an olefin polymerization catalyst including the ansa-metallocene compound is provided.

[0075] The ansa-metallocene compound according to the present invention can be used as an olefin polymerization catalyst by itself, or can be used as a catalyst precursor together with a cocatalyst as an olefin polymerization catalyst.

[0076] The olefin polymerization catalyst may be a catalyst supported on a carrier.

[0077] As the support, those generally used in the art can be used without particular limitation, and preferably, at least one selected from silica, silica-alumina, silica-magnesia can be used kind. When the catalyst is supported on a silica carrie...

Embodiment 1

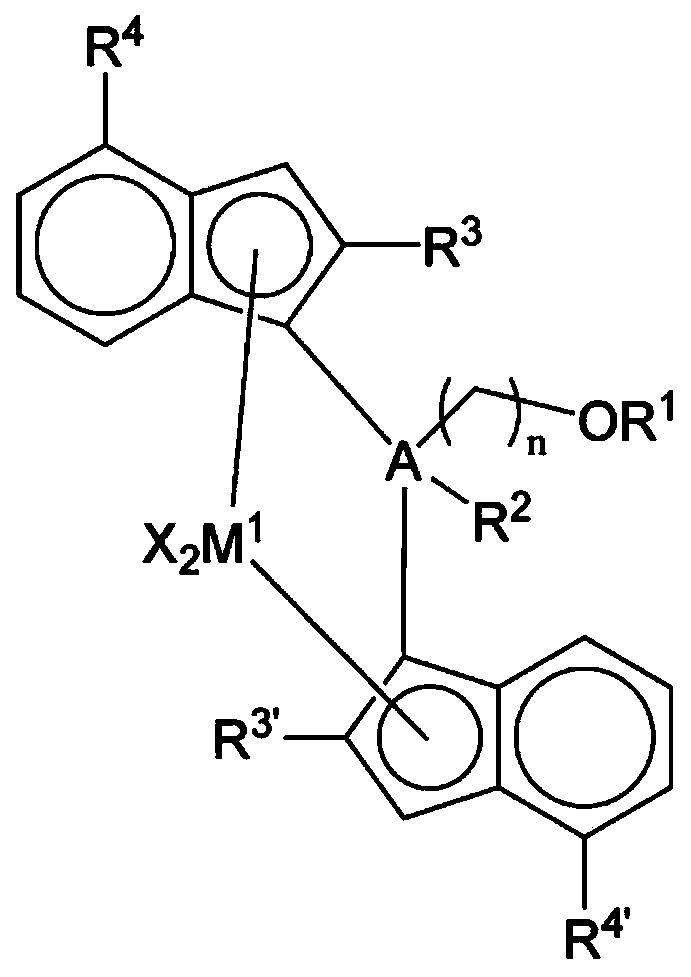

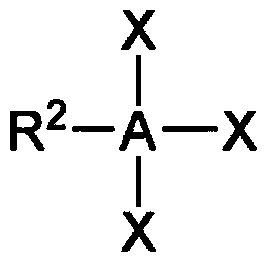

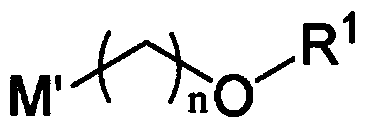

[0111]The ansa-metallocene compound of Chemical Formula 2 and the olefin polymerization supported catalyst including the ansa-metallocene compound were prepared under the conditions described in Table 1 below.

[0112] [chemical formula 2]

[0113]

[0114] Synthesis of metallocenes

[0115] Step 1: Synthesis of (6-tert-butoxyhexyl)methyldichlorosilane

[0116] Slowly drop 100 mL of tert-butoxy into 100 mL of methyltrichlorosilane solution (about 0.21 mol, hexane) at -100 base Hexylmagnesium chloride solution (approximately 0.14 mol, diethyl ether) for 3 hours, followed by stirring at room temperature for 3 hours.

[0117] After separation of the clear organic layer from the solution mixture, the clear organic layer thus formed was vacuum dried and excess methyltrichlorosilane was removed to obtain (6-tert-butoxyhexyl)methyldichlorosilane as a clear liquid (Yield 84%).

[0118] 1 H NMR (500MHz, CDCl 3 ,7.24ppm):0.76(3H,s),1.11(2H,t),1.18(9H,s),1.32~1.55(8H,m),3.33...

preparation Embodiment 1~2 and comparative preparation Embodiment 1~4

[0181] Polypropylene polymers were prepared using the metallocene catalysts prepared in Example 1 and Comparative Examples 1 to 4, respectively, as follows.

[0182] Propylene polymerization

[0183] First, a 2 L stainless steel reactor was dried and cooled at 65° C., 1.5 mmol of triethylaluminum was added thereto at room temperature, and then 0.37 L of hydrogen and 1.5 L of propylene were sequentially added. Thereafter, the mixture was stirred for 10 minutes, and then 0.019 g of each metallocene catalyst prepared in Example 1 and Comparative Examples 1 to 3 was added to the reactor under a nitrogen atmosphere. At this point, hydrogen was added simultaneously with the metallocene catalyst. Subsequently, the temperature of the reactor was slowly raised to 70° C., at which temperature polymerization was performed for 1 hour. After the reaction is completed, unreacted propylene monomer is discharged.

[0184] The content and activity of the catalyst and the properties of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| process yield | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com