Ramming material for iron notch of smelting reduction furnace

A technology of ramming material and taphole, which is applied in the field of refractory materials, can solve the problems of large outflow of molten iron, easy shallowing of the taphole area, and affecting the service life of the taphole, so as to achieve good plasticity and construction performance, and improve strength and corrosion resistance, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

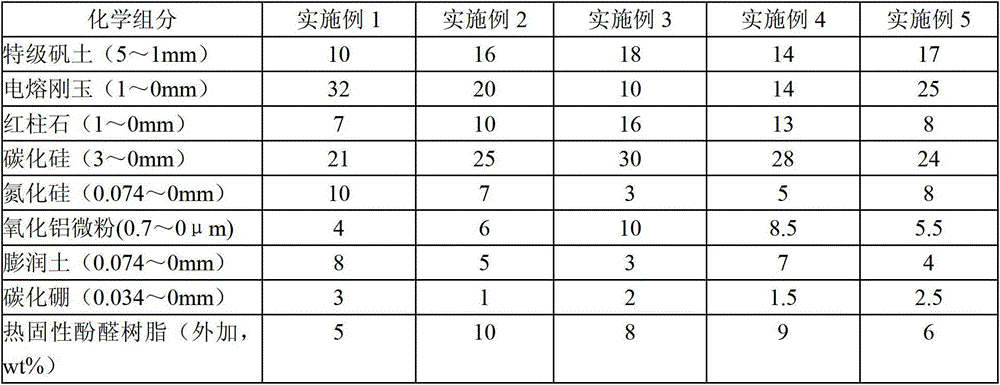

[0038] Dosing according to the ingredient distribution ratio shown in Table 1; after mixing uniformly for 10 minutes, add thermosetting phenolic resin as an anhydrous binder to combine the chemical components together; stir and roll for 15 minutes; seal and pack in blocks.

[0039] Table 1

[0040]

[0041] After firing the ramming material for the taphole of the smelting reduction furnace in Examples 1-5 at 1450° C. for 3 hours, the technical parameters were measured, and the test method was referred to the corresponding national standard or industry standard for refractory materials. Table 2 lists the technical parameters of the physical properties of the ramming material for the taphole of the smelting reduction furnace in Examples 1-5 after testing.

[0042] Table 2

[0043]

comparative example

Example 1

Example 2

Example 3

Example 4

Example 5

Compressive strength, MPa

32.8

63.6

57.4

60.9

61.1

59.6

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com