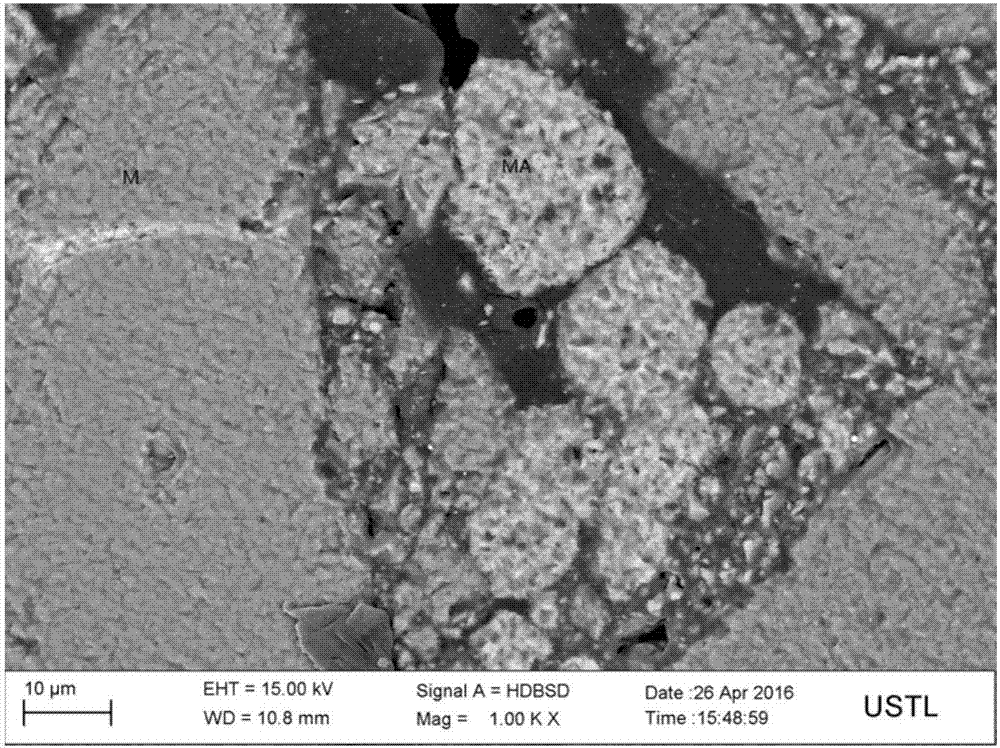

Unburned magnesia-carbon brick and preparation method thereof

A technology of magnesia-carbon bricks and complexed magnesium, which is applied in the field of advanced refractory materials, can solve the problems of mastering the details of the preparation process, high product costs, explosions, etc., and achieve the effects of improving workers' working conditions, saving economic costs, and overcoming high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

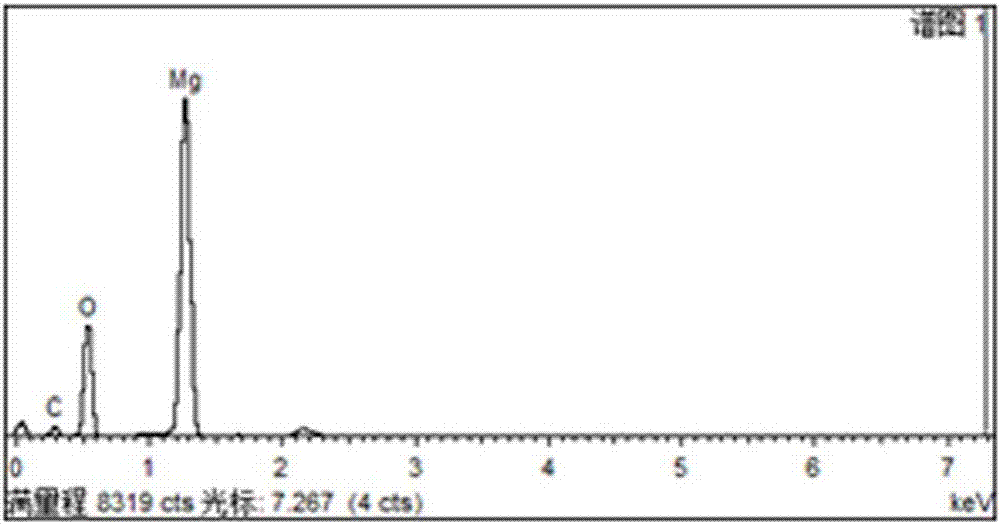

Method used

Image

Examples

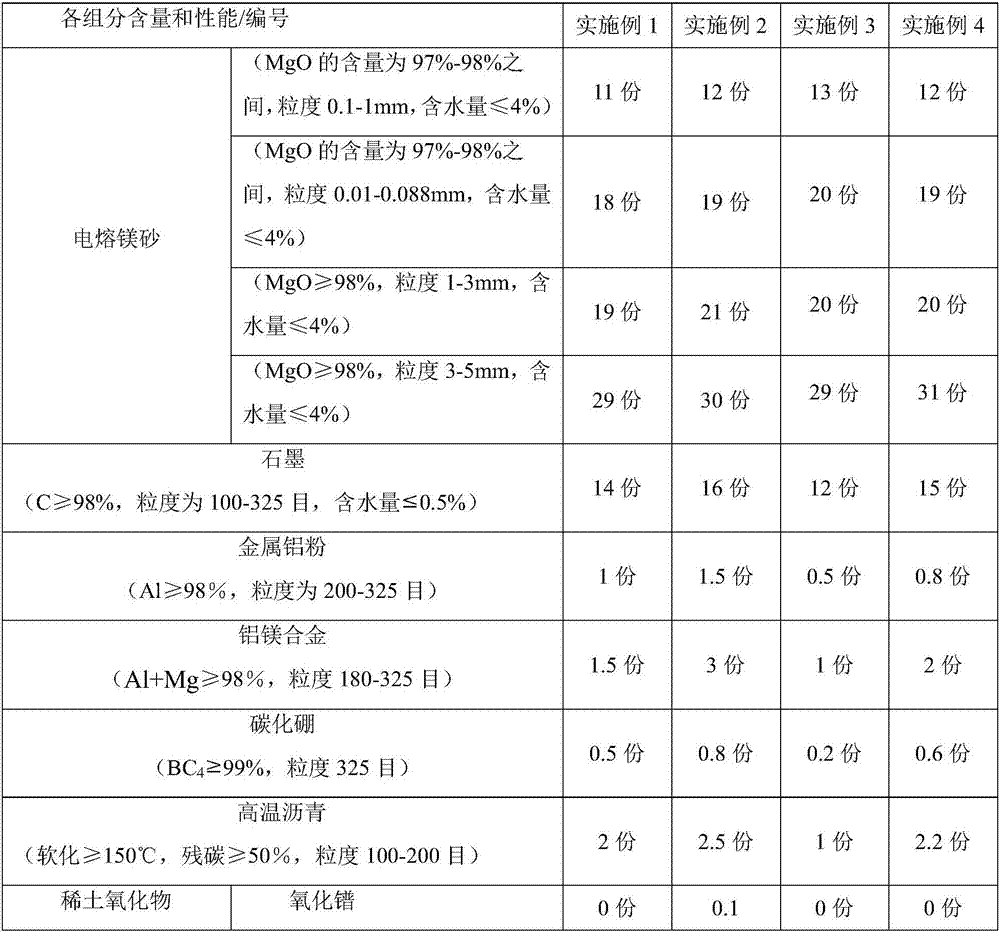

Embodiment 1

[0030] The raw materials were weighed according to the components specified in Table 1 below, and the preparation method was as follows.

[0031] (1) Raw material processing: Weigh the fused magnesia according to the weight and put it into the jaw crusher for crushing. After crushing into large particles, it will be crushed by double rollers, and then the aggregate with a particle size of 0.1-5mm will be screened out with a vibrating screen. , and then according to the proportion of the formula according to the weight of particle size 0.1-1mm, particle size 0.01-0.088mm, particle size 1-3mm, and particle size 3-5mm, the corresponding parts are screened out, and then reasonably distributed for the next step of crushing, it will take two times Put the pulverized fused magnesia into the Raymond mill for preparation, weigh high-temperature asphalt, metal aluminum powder, magnesium-aluminum alloy, boron carbide, rare earth oxides and ceramic binders to the above materials, and crush...

Embodiment 2

[0044] The method of Example 1 was repeated at the contents of each component specified in Table 1 below, and the test results are listed in Table 3.

Embodiment 3

[0046] The method of Example 1 was repeated at the contents of each component specified in Table 1 below, and the test results are listed in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com