Method for growing zinc oxide monocrystalline under hydrothermal condition by utilizing mineralizer

A technology of zinc oxide and conditions, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problems of high requirements and high heating temperature of hydrothermal reactors and their substrates, and achieve low cost and high growth rate. The effect of fast speed and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

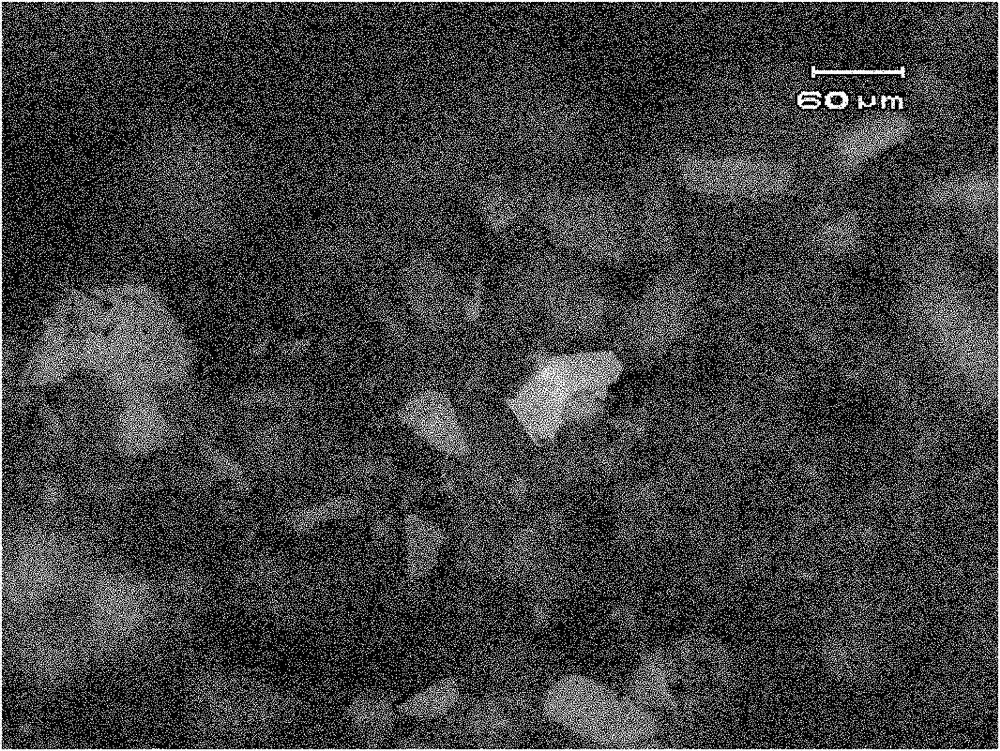

[0030] The zinc hydroxide suspension is used as the growth material, and a high-temperature alloy steel with an inner diameter of Φ4cm and a height of 9cm is used to make a high-pressure reactor. The high-pressure reactor is lined with polytetrafluoroethylene. Fill the reactor with deionized water, use sodium chloride as the mineralizer, and control the chloride ion concentration in the solution to 0.05 mol / L. Add sodium hydroxide solution to adjust the pH value of the hydrothermal solution to 6. At the same time, make the filling degree of the autoclave 60%. Place a zinc wire as a seed crystal in the solution in the upper part of the autoclave, and seal the mouth of the kettle. The autoclave was heated by microwave so that the temperature of the autoclave was kept constant at 90°C. After holding for 1 day, ZnO microcrystals can be grown on the seed crystals. Such as figure 2 Shown.

Embodiment 2

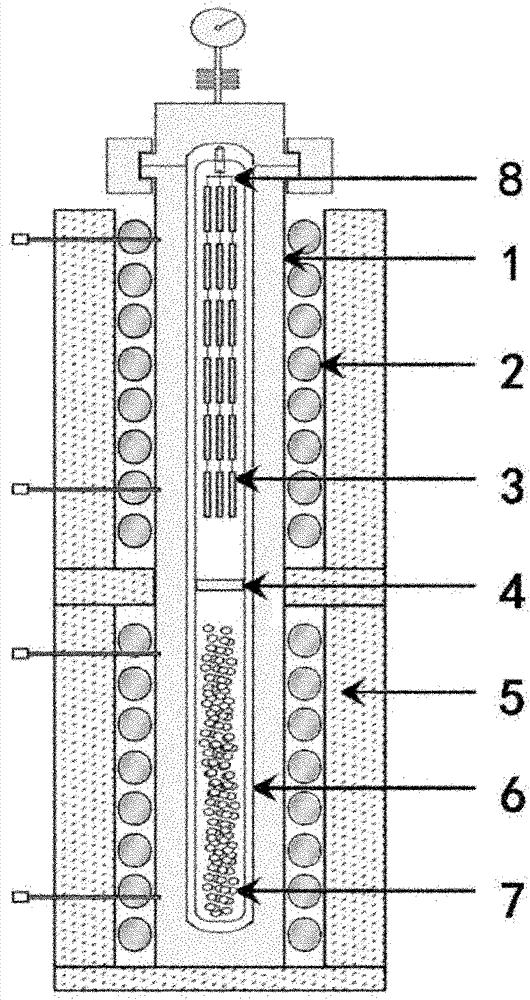

[0032] Take 1 kg of zinc hydroxide compact pieces as the growth material 7, and place them on the bottom of the high-pressure reactor 1 made of high-temperature alloy steel with an inner diameter of Φ8cm and a height of 0.5m. The inner lining 6 is polytetrafluoroethylene, and an insulation layer 5 is provided outside the high-pressure reactor. Fill the reaction kettle with deionized water, use a mixture of zinc chloride and sodium chloride (0.25mol / lZnCl2+0.5mol / l NaCl) as the mineralizer, add a certain amount of sodium hydroxide to The pH value is adjusted to 9, and the chloride ion concentration in the solution is controlled to 1mol / L. At the same time, the filling degree of the autoclave is made 80%. After placing (0001)-oriented ZnO seed crystals 3 in the solution in the upper part of the autoclave, the seed crystal holder 8 is used to seal the mouth of the autoclave. Use nickel-chromium resistance wires to heat the autoclave in two upper and lower sections; a set of resi...

Embodiment 3

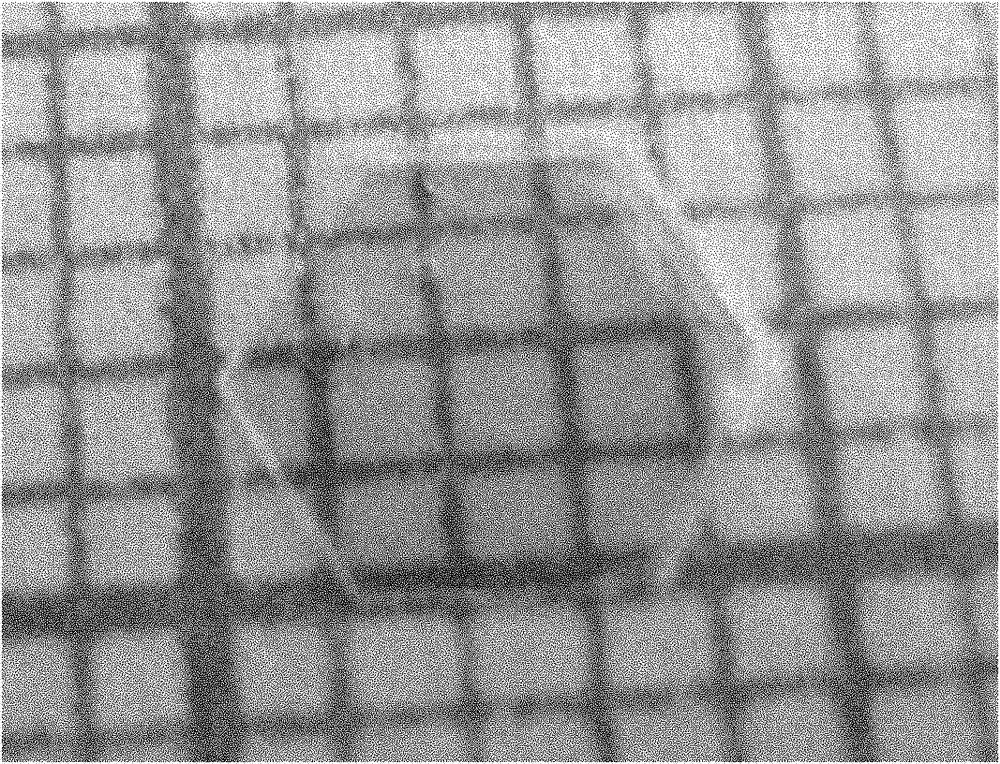

[0034] 1 kg of zinc oxide compacts were used as growth materials, placed in high temperature alloy steel with an inner diameter of Φ8cm and height of 0.5m to make the bottom of the autoclave, a partition was added above the zinc oxide growth materials, and the high pressure reactor was lined with metallic silver. Fill the autoclave with deionized water, use a mixture of lithium chloride and sodium chloride (0.25mol / l LiCl+0.75mol / l NaCl) as a mineralizer, add sodium hydroxide solution to adjust the pH to 10. The concentration of chloride ion in the control solution is 1mol / L. At the same time, make the filling degree of the autoclave 90% (volume). After placing (0001) oriented ZnO seed crystals in the upper solution of the autoclave, the mouth of the autoclave was sealed. Use nickel-chromium-aluminum resistance wire to heat the autoclave in two sections, the upper and lower sections; the temperature of a group of resistance wires at the bottom of the kettle is raised to 280℃; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com