Vibrating material and preparation method thereof

A technology of vibration material and preparation steps, which is applied in the field of vibration material and its preparation, can solve the problems of poor slag erosion resistance, short service life, and low sintering strength, and achieve the effects of reducing pollution, increasing service life, and improving sintering strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

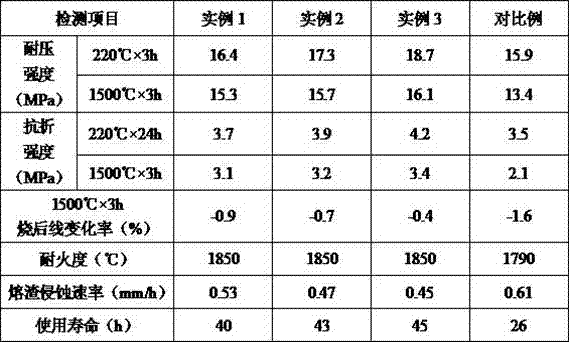

Examples

example 1

[0027] According to the mass ratio of 5:1:100, respectively weigh carob bean gum, sodium carboxymethyl starch and water and mix them, stir and mix for 10 minutes, then add 1% carob bean gum mass fraction 5% ammonium persulfate solution, and then heat to 80°C , stirred and reacted for 1 hour, cooled to room temperature after the reaction, and discharged to obtain the carob gum reactant, then weighed sodium alginate and added it to water at a mass ratio of 1:10, stirred for 20 minutes and then heated to 40°C to obtain sodium alginate solution, followed by adding sodium alginate solution quality 5% carob gum reactant, sodium alginate solution quality 15% hydroxyethyl methacrylate, sodium alginate solution quality 2% vinyl acetate and sodium alginate solution quality 1% Ammonium persulfate is discharged after stirring and reacting to obtain viscous matter, then in parts by weight, get 60 parts of viscous matter, 5 parts of silicon dioxide, 5 parts of lime powder and 2 parts of verm...

example 2

[0029]According to the mass ratio of 5:1:100, weigh carob bean gum, sodium carboxymethyl starch and water to mix, stir and mix for 15 minutes, add carob bean gum mass fraction 5% ammonium persulfate solution, and then heat to 83°C , stirred and reacted for 2 hours, cooled to room temperature after the reaction, and discharged to obtain the carob gum reactant, then weighed sodium alginate and added it to water at a mass ratio of 1:10, stirred for 25 minutes and then heated to 45°C to obtain sodium alginate solution, followed by adding sodium alginate solution quality 8% carob gum reactant, sodium alginate solution quality 18% hydroxyethyl methacrylate, sodium alginate solution quality 3% vinyl acetate and sodium alginate solution quality 2% Ammonium persulfate is discharged after stirring and reacting to obtain viscous matter, and then in parts by weight, 65 parts of viscous matter, 8 parts of silicon dioxide, 6 parts of lime powder and 3 parts of kaolinite are obtained after st...

example 3

[0031] According to the mass ratio of 5:1:100, weigh carob bean gum, sodium carboxymethyl starch and water to mix, stir and mix for 20 minutes, add carob bean gum mass fraction 5% ammonium persulfate solution, and then heat to 85°C , stirred and reacted for 3 hours, cooled to room temperature after the reaction, and discharged to obtain the carob gum reactant, then weighed sodium alginate and added it to water at a mass ratio of 1:10, stirred for 30 minutes and then heated to 50°C to obtain sodium alginate solution, followed by adding sodium alginate solution quality 10% carob gum reactant, sodium alginate solution quality 20% hydroxyethyl methacrylate, sodium alginate solution quality 4% vinyl acetate and sodium alginate solution quality 3% Ammonium persulfate is discharged after stirring and reacting to obtain viscous matter, and then in parts by weight, 70 parts of viscous matter, 10 parts of silicon dioxide, 7 parts of lime powder and 4 parts of montmorillonite are obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com