Dry material for continuous casting tundish working lining and preparation method of dry material

A continuous casting tundish and working lining technology, applied in casting equipment, metal processing equipment, manufacturing tools, etc., can solve unfavorable clean steelmaking and environmental protection requirements, can not meet the use requirements for a long time, compact structure and poor thermal insulation performance, etc. problems, to achieve excellent corrosion resistance to molten steel and slag, good environmental compatibility, and good performance in slag corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A dry material for continuous casting tundish working lining, the preparation method of which comprises the following steps:

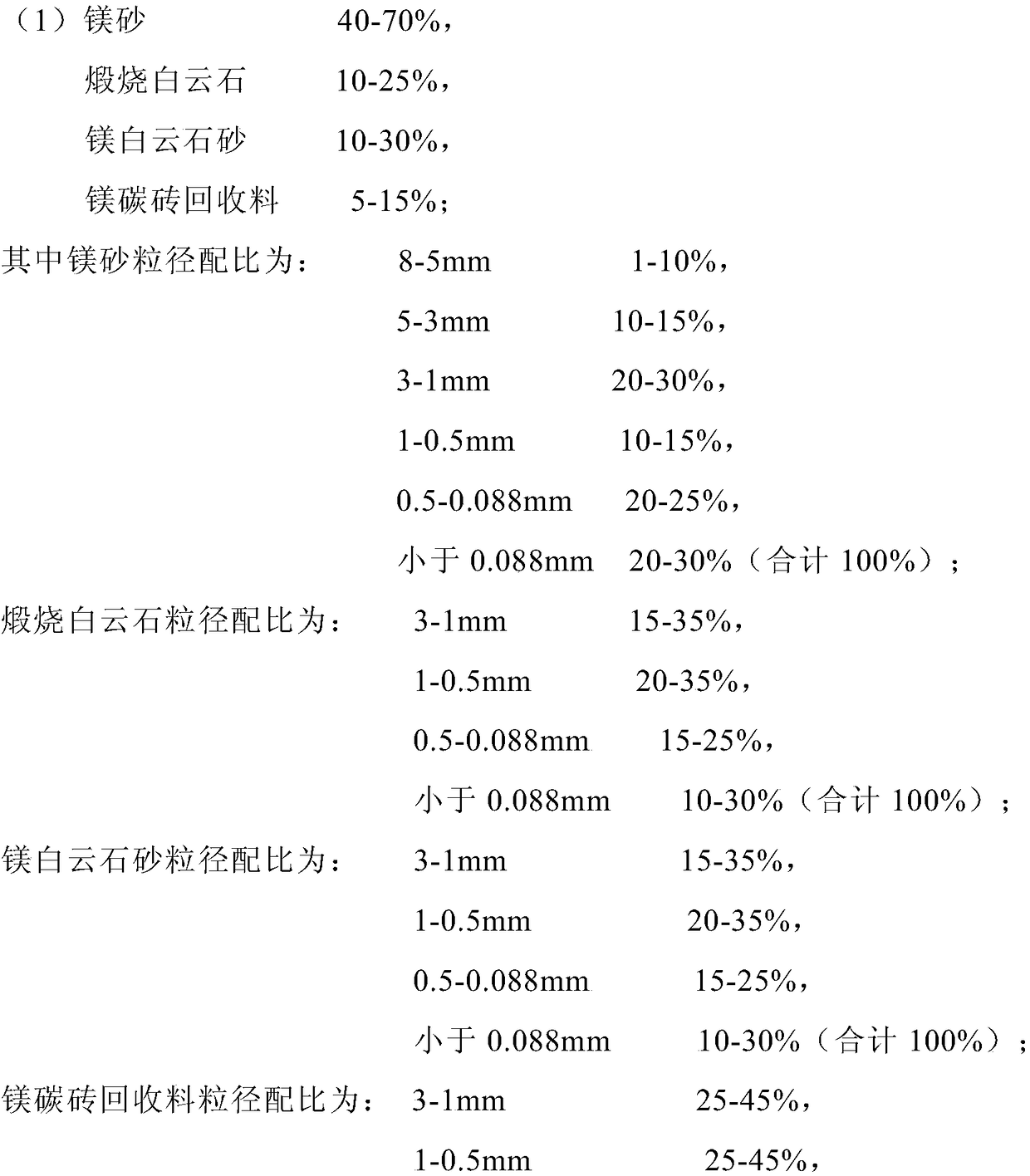

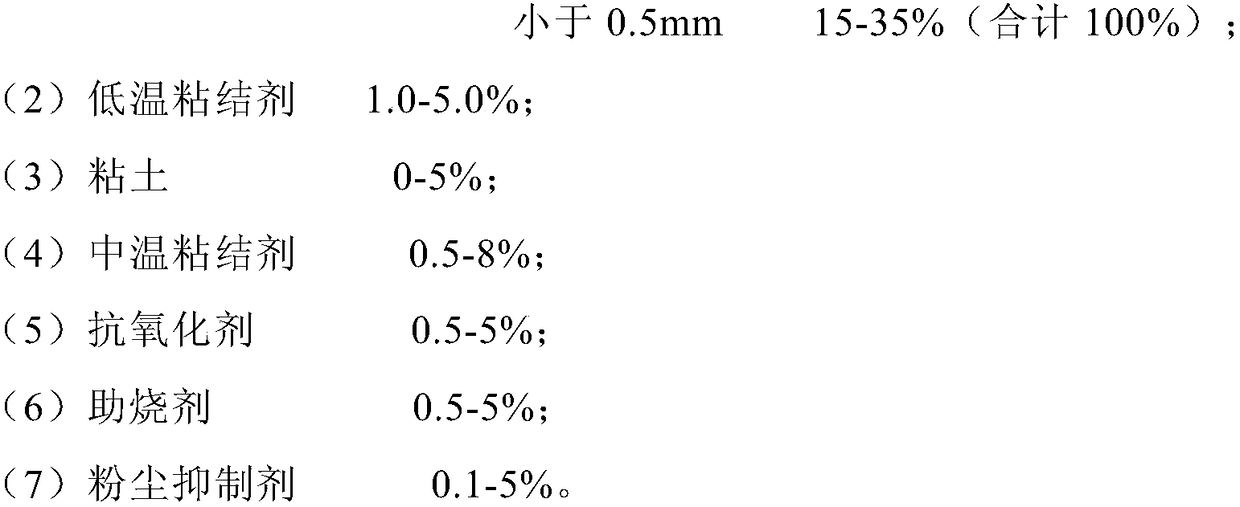

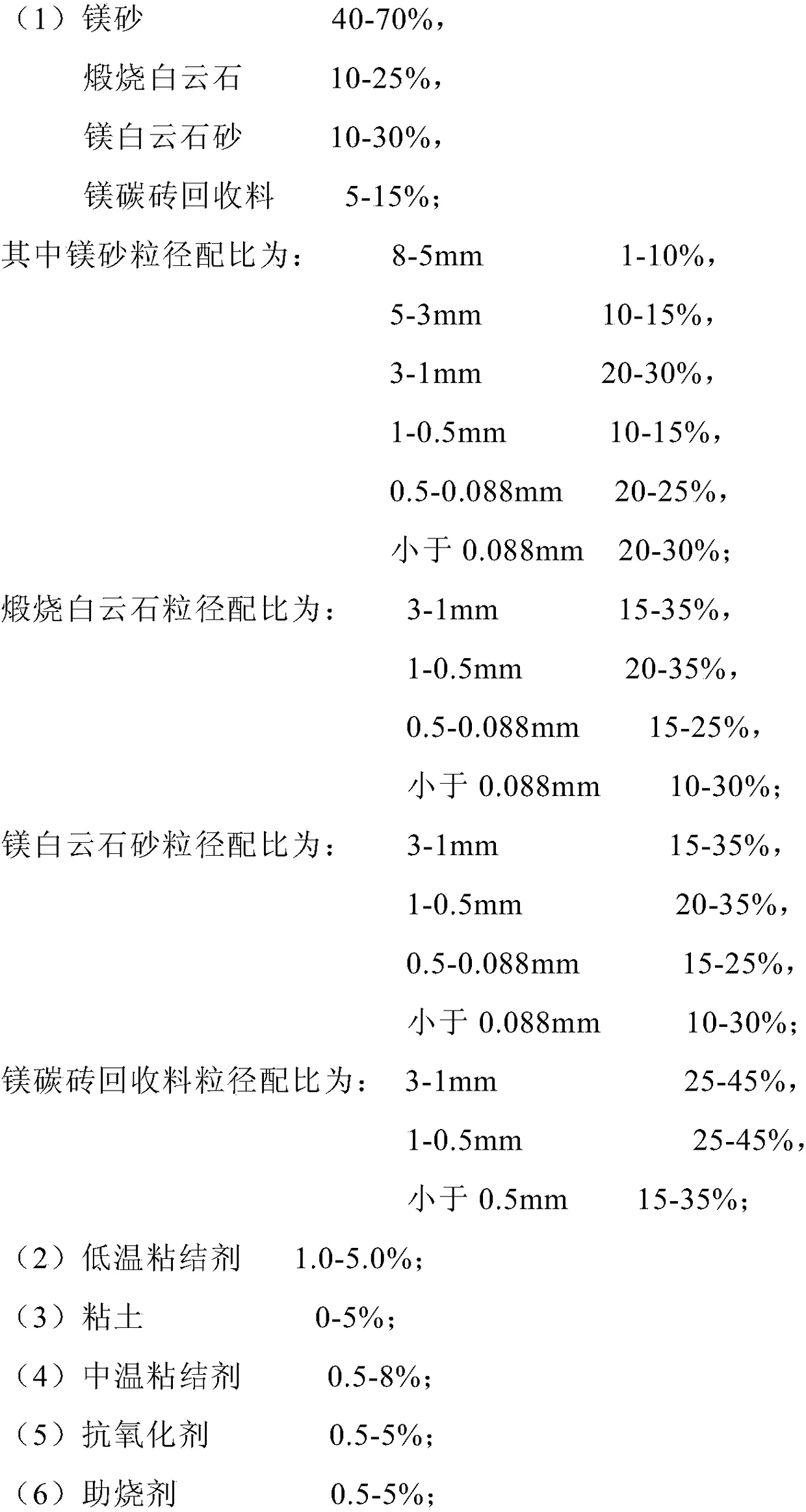

[0030] 1) select raw materials by the following mass percentages:

[0031] (1) Main raw materials: magnesia 55%, calcined dolomite 20%, magnesia dolomite sand 10% (of which MgO content is 65%), magnesia carbon brick recycled material 5%;

[0032] The particle size ratio of magnesia used is: 8-5mm accounts for 10%, 5-3mm accounts for 10%, 3-1mm accounts for 25%, 1-0.5mm accounts for 10%, 0.5-0.088mm accounts for 20%, and less than 0.088mm accounts for 20%. 25%; the particle size ratio of calcined dolomite used is: 3-1mm accounts for 20%, 1-0.5mm accounts for 30%, 0.5-0.088mm accounts for 25%, and less than 0.088mm accounts for 25%; the particle size of magnesium dolomite sand used The proportion is: 3-1mm accounts for 20%, 1-0.5mm accounts for 25%, 0.5-0.088mm accounts for 25%, less than 0.088mm accounts for 30%; 35%, 1-0.5mm accounted for 35%,...

Embodiment 2

[0044] A dry material for continuous casting tundish working lining, the preparation method of which comprises the following steps:

[0045] 1) select raw materials by the following mass percentages:

[0046] (1) Main raw materials: magnesia 70%, calcined dolomite 10%, magnesia dolomite sand 10% (of which MgO content is 50%), magnesia carbon brick recycled material 5%;

[0047] The particle size ratio of magnesia used is: 8-5mm accounts for 5%, 5-3mm accounts for 10%, 3-1mm accounts for 20%, 1-0.5mm accounts for 10%, 0.5-0.088mm accounts for 25%, and less than 0.088mm accounts for 25%. 30%; the particle size ratio of calcined dolomite used is: 3-1mm accounts for 35%, 1-0.5mm accounts for 20%, 0.5-0.088mm accounts for 15%, less than 0.088mm accounts for 30%; the particle size of magnesium dolomite sand used The proportion is: 3-1mm accounts for 25%, 1-0.5mm accounts for 35%, 0.5-0.088mm accounts for 25%, less than 0.088mm accounts for 15%; 40%, 1-0.5mm accounted for 40%, less...

Embodiment 3

[0060] A dry material for continuous casting tundish working lining, the preparation method of which comprises the following steps:

[0061] 1) select raw materials by the following mass percentages:

[0062] (1) Main raw materials: magnesia 40%, calcined dolomite 25%, magnesia dolomite sand 10% (including MgO content of 70%), magnesia carbon brick recycled material 15%;

[0063] The particle size ratio of magnesia used is: 8-5mm accounts for 10%, 5-3mm accounts for 15%, 3-1mm accounts for 20%, 1-0.5mm accounts for 12%, 0.5-0.088mm accounts for 20%, and less than 0.088mm accounts for 20%. 23%; the particle size ratio of calcined dolomite used is: 3-1mm accounts for 30%, 1-0.5mm accounts for 25%, 0.5-0.088mm accounts for 20%, less than 0.088mm accounts for 25%; the particle size of magnesium dolomite sand used The proportion is: 3-1mm accounts for 20%, 1-0.5mm accounts for 30%, 0.5-0.088mm accounts for 20%, less than 0.088mm accounts for 30%; 40%, 1-0.5mm accounted for 45%, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com