Al-Mg-C brick for steel ladle lining

A technology of aluminum magnesia carbon bricks and ladle furnaces, which is applied to casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of high carbon content, which is unfavorable for ultra-clean steel production, difficult to meet the requirements of refining processes, etc., and achieves volume maintenance. Stability, good social and economic benefits, and the effect of improving slag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

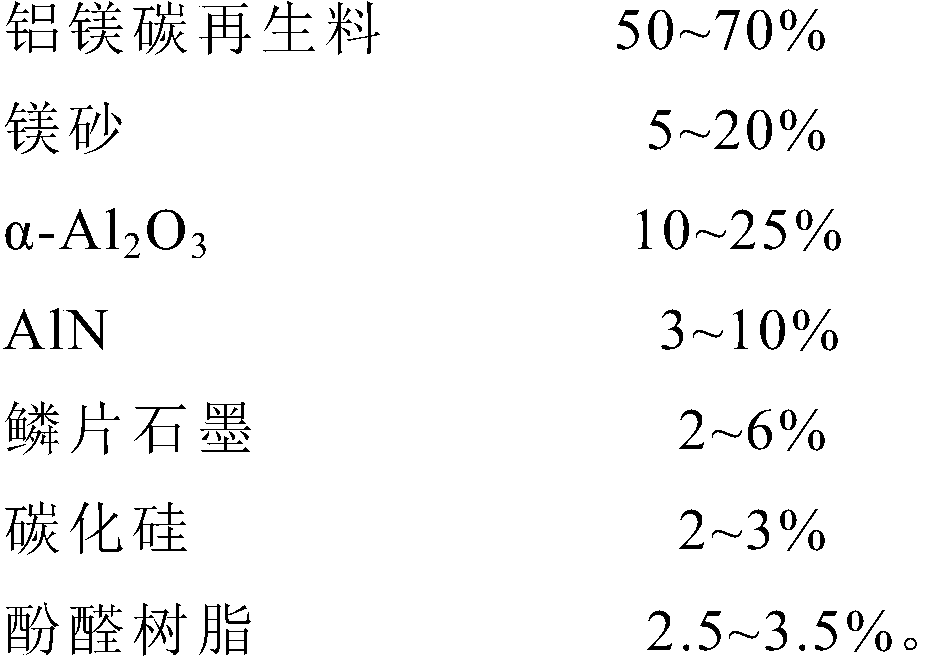

[0024] Alumina-magnesia-carbon bricks include the following raw materials by weight percentage:

[0025]

[0026] Wherein, Al in the aluminum-magnesium-carbon recycled material 2 o 3 The mass percentage of the alumina-magnesia-carbon brick is ≥ 45%, and the particle size of the alumina-magnesia-carbon brick recycled material is 0.088mm≤particle size≤6mm, wherein: the alumina-magnesia-carbon brick recycled material with a particle size of 0.088mm≤particle size≤1mm accounts for 5% of the total mass of the alumina-magnesia-carbon brick recycled material , 1mm ≤ particle size ≤ 3mm aluminum magnesium carbon brick recycled materials accounted for 50% of the total mass of aluminum magnesium carbon brick recycled materials, 3mm ≤ particle size ≤ 5mm aluminum magnesium carbon brick recycled materials accounted for 45% of the total mass of aluminum magnesium carbon brick recycled materials ; The mass percentage of MgO in magnesia is ≥97%, and the particle size of magnesia is ≤1mm, ...

Embodiment 2

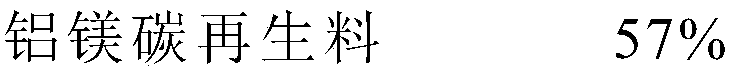

[0029] Alumina-magnesia-carbon bricks include the following raw materials by weight percentage:

[0030]

[0031] Wherein, Al in the aluminum-magnesium-carbon recycled material 2 o 3 The mass percentage of the alumina-magnesia-carbon brick is ≥ 45%, and the particle size of the alumina-magnesia-carbon brick recycled material is 0.088mm≤particle size≤6mm, wherein: the alumina-magnesia-carbon brick recycled material with a particle size of 0.088mm≤particle size≤1mm accounts for 5% of the total mass of the alumina-magnesia-carbon brick recycled material , 1mm ≤ particle size ≤ 3mm aluminum magnesium carbon brick recycled materials accounted for 50% of the total mass of aluminum magnesium carbon brick recycled materials, 3mm ≤ particle size ≤ 5mm aluminum magnesium carbon brick recycled materials accounted for 45% of the total mass of aluminum magnesium carbon brick recycled materials ; The mass percentage of MgO in magnesia is ≥97%, and the particle size of magnesia is ≤1mm, ...

Embodiment 3

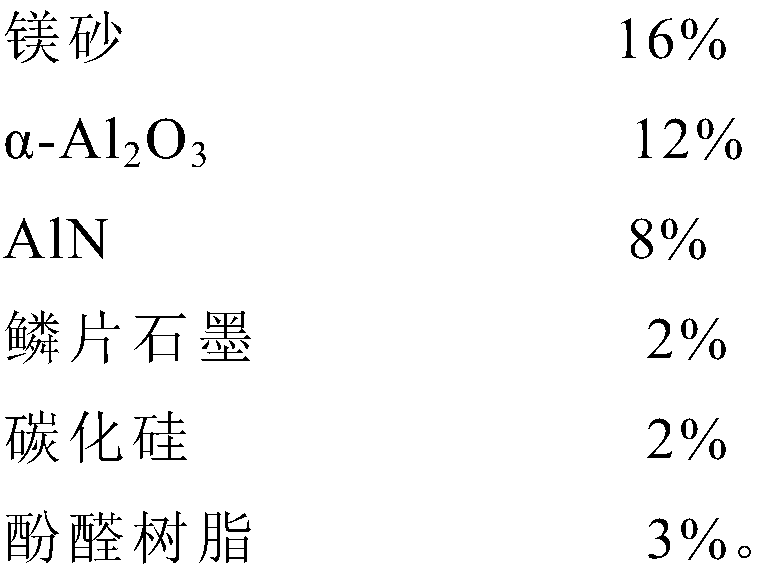

[0034] Alumina-magnesia-carbon bricks include the following raw materials by weight percentage:

[0035]

[0036] Wherein, Al in the aluminum-magnesium-carbon recycled material 2 o 3 The mass percentage of aluminum-magnesium-carbon bricks is ≥45%, and the particle size of the recycled materials for aluminum-magnesia-carbon bricks is 0.088mm≤particle size≤6mm, among which: the recycled materials for aluminum-magnesium-carbon bricks with a particle size of 0.088mm≤1mm account for 5% of the total mass of recycled materials for aluminum-magnesia-carbon bricks , 1mm ≤ particle size ≤ 3mm aluminum magnesium carbon brick recycled materials accounted for 50% of the total mass of aluminum magnesium carbon brick recycled materials, 3mm ≤ particle size ≤ 5mm aluminum magnesium carbon brick recycled materials accounted for 45% of the total mass of aluminum magnesium carbon brick recycled materials ; The mass percentage of MgO in magnesia is ≥97%, and the particle size of magnesia is ≤...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com