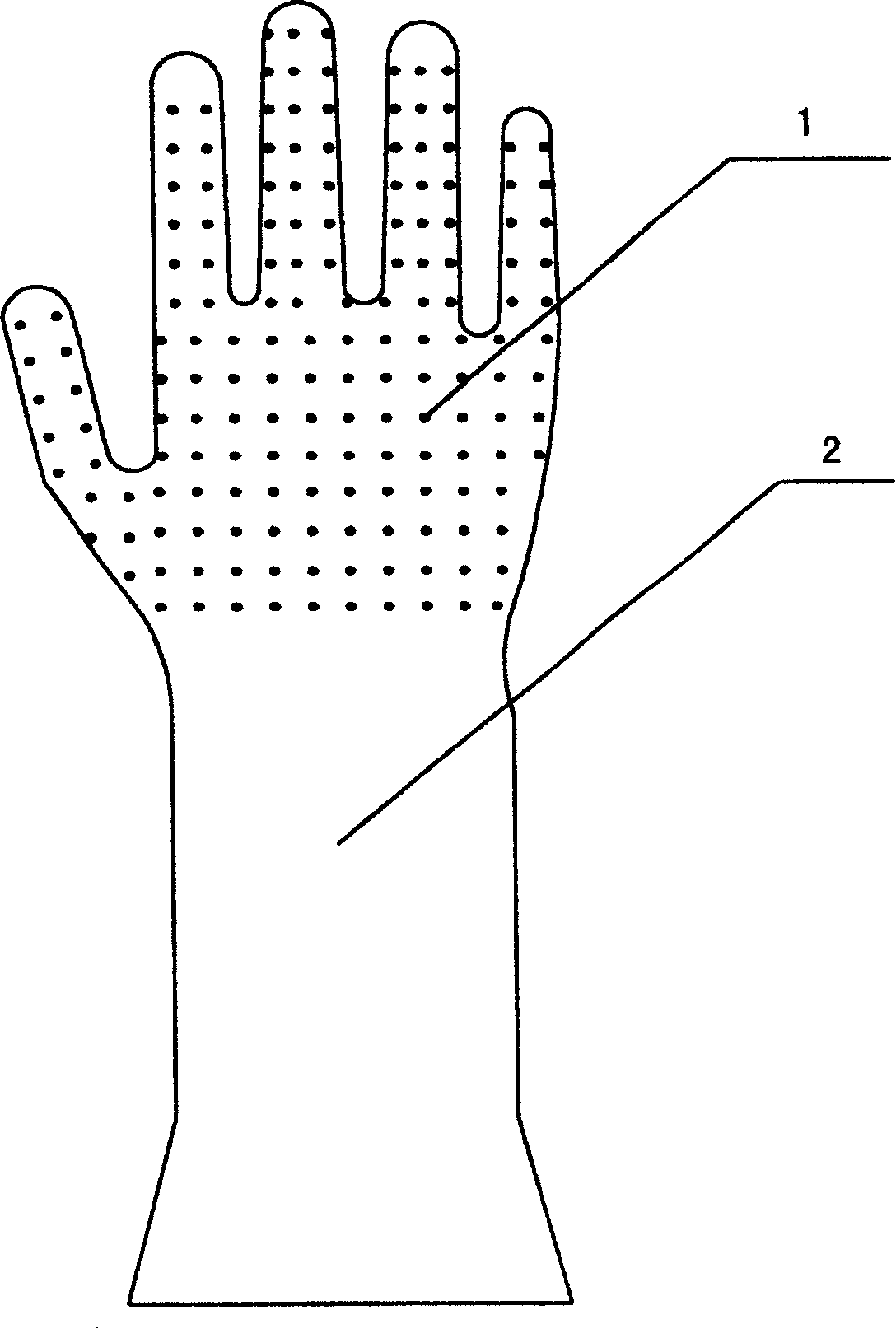

Ceramic hand model suitable for acrylonitrile butadiene glove production and its making method

A technology of nitrile rubber and hand molding, which is applied in applications, household components, household appliances, etc., can solve the problems of low production pass rate, poor thermal shock resistance, high shrinkage rate, etc., and achieve high product pass rate and acid resistance Strong alkali corrosion and the effect of increasing the number of thermal shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Raw material formula: 7% of quartz, 12% of feldspar, 45% of cooked Datong soil, 16% of Fangzi soil, 2% of Suzhou soil, 10% of cooked bauxite, 8% of cooked talc; according to the formula, send it into the ball mill Add water and grind for 38h-40h to make mud; the mud passes through a 300-mesh vibrating screen to make mud with a fineness of 300 mesh, and then puts it into a mud filter machine after iron removal by a permanent magnet iron remover, and separates it with an industrial filter cloth in the mud machine Make the mud cake; add appropriate amount of water to the mud cake and stir, and add soda ash and water glass according to the weight ratio of 0.3%-0.5%, and beat it into mud. The specific gravity of the mud is 1.7g / cm 3 -1.8g / cm 3, and then after the second iron removal treatment, the mud is stale for 24 hours after secondary screening with a 200-260-mesh vibrating screen, and then pumped into a high-level storage tank; pressure grouting, and then the hand mold ...

Embodiment 2

[0037] Preparation method is identical with embodiment 1.

[0038] Raw material formula: 8% quartz, 22% feldspar, 32% cooked Datong soil, 10% Fangzi soil, 3% Suzhou soil, 20% cooked bauxite, 5% cooked talc. The weight content of the chemical components of the finished ceramic hand touch is: SiO 2 55.42%, Al 2 o 3 37.83%, Fe 2 o 3 0.25%, TiO 2 0.41%, CaO 0.44%, MgO 0.48%, K 2 O 3.85%, Na 2 O 1.60%, loss on ignition 1.00%. The total shrinkage of the hand mold was 8%.

Embodiment 3

[0040] Preparation method is identical with embodiment 1.

[0041] Raw material formula: 6% of quartz, 16% of feldspar, 40% of cooked Datong soil, 4% of Fangzi soil, 2% of Suzhou soil, 30% of cooked bauxite, and 2% of cooked talc. The weight content of the chemical components of the finished ceramic hand touch is: SiO 2 3 1.50%, Al 2 o 3 58%, Fe 2 o 3 0.37%, TiO 2 0.25%, CaO 0.34%, MgO 0.52%, K 2 O 2.58%, Na 2 O 1.57%, loss on ignition 4.87%. The total shrinkage of the hand mold was 6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com