Honeycomb type selective catalytic reduction denitration catalyst and preparation method thereof

A denitration catalyst and selective technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. The effect of improving wear performance, improving conversion rate, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In the preparation method of the honeycomb type selective catalytic reduction denitration catalyst of the present invention, it is divided into four steps: mixing, forming, drying and calcining in sequence. Specifically, (a) Mixing: first add deionized water to the co-catalyst precursor to form a solution, then add titanium dioxide, clay, static eliminator, mold release agent, and pH regulator in sequence, at 70~80°C Stir and control the water content to 25%~27%, then add the active component precursor, pore forming agent, and reinforcing agent in sequence, continue stirring for 10~30 minutes, and then add water-retaining binder to form a water content of 28.5~29.5%. Mud;

[0036] (b) Forming: put the mud obtained in step (a) stale for 10-20 hours at a room temperature above 20°C, filter and directly extrude into a honeycomb embryo body;

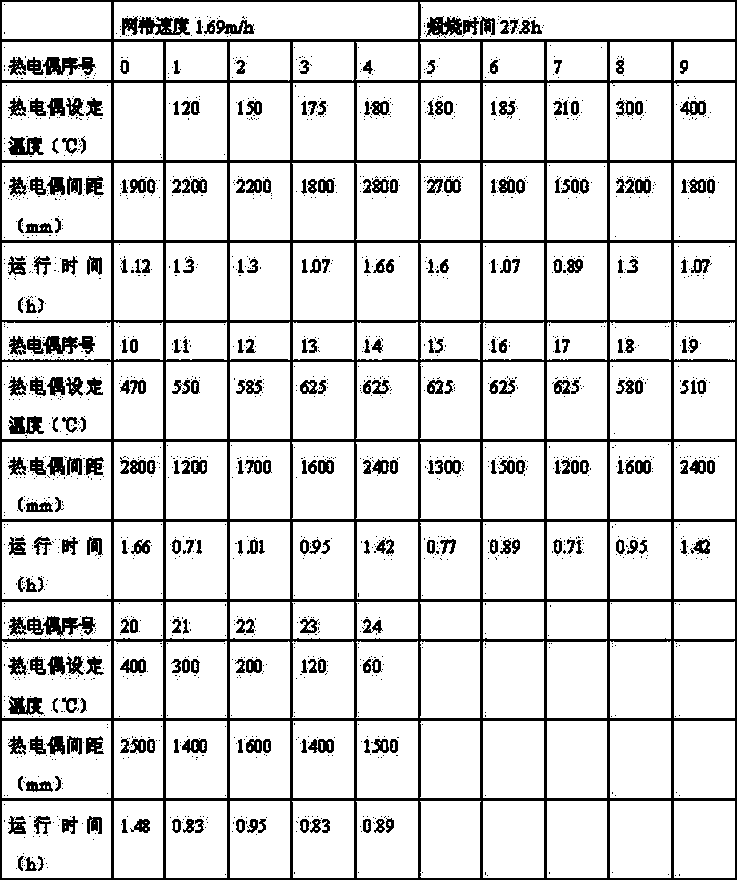

[0037] (c) Drying: dehydrating and drying the honeycomb embryo body obtained in step (b), to obtain a dry product with a transverse...

Embodiment 1

[0045] Honeycomb selective catalytic reduction denitrification catalyst, its raw material formula is as follows:

[0046] Titanium dioxide 78kg;

[0047] Clay 6kg;

[0048] Active component precursor 1.5kg;

[0049] Co-catalyst precursor 5kg;

[0050] Static Eliminator 0.5kg;

[0051] Release agent 0.3kg;

[0052] pH regulator 0.4kg;

[0053] Pore-forming agent 0.8kg;

[0054] Enhancer 5kg;

[0055] Water-retaining adhesive 2.5kg,

[0056] The preparation method of above-mentioned catalyst comprises the steps:

[0057] (a) Mixing: Add co-catalyst precursor and appropriate amount of deionized water into the mixer according to the above formula amount to make a solution, and then add the formula amount of titanium dioxide, clay, static eliminator, mold release agent, and pH regulator in sequence , Stir at 70-80°C and control the moisture content to 25%-27%, add the active component precursor, pore-forming agent, and reinforcing agent in sequence, continue stirring for 1...

Embodiment 2

[0062] Honeycomb selective catalytic reduction denitrification catalyst, its raw material formula is as follows:

[0063] Titanium dioxide 84.5kg;

[0064] Clay 4kg;

[0065] Active component precursor 0.5kg;

[0066] Co-catalyst precursor 4.5kg;

[0067] Static Eliminator 0.2kg;

[0068] Release agent 0.1kg;

[0069] pH adjuster 0.1kg;

[0070] Pore-forming agent 0.3kg;

[0071] Enhancer 4kg;

[0072] Water-retaining adhesive 1.8kg;

[0073] Catalyst scrap 11.1kg,

[0074] The preparation method of above-mentioned catalyst comprises the steps:

[0075] (a) Mixing: Add co-catalyst precursor and appropriate amount of deionized water into the mixer according to the above formula amount to make a solution, and then add the formula amount of titanium dioxide, clay, static eliminator, mold release agent, and pH regulator in sequence , and add the crushed catalyst scraps in the formula amount, stir at 70-80°C and control the moisture content to 25%-27%, add the active comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com