Nano-rare earth tungsten powder and its preparation method

A nano-rare earth and tungsten powder technology, applied in the field of powder metallurgy, can solve the problems of uneven distribution of rare earth elements, difficult replenishment of rare earth oxides, process repeatability, high temperature resistance, ion bombardment resistance, and unsatisfactory emission uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

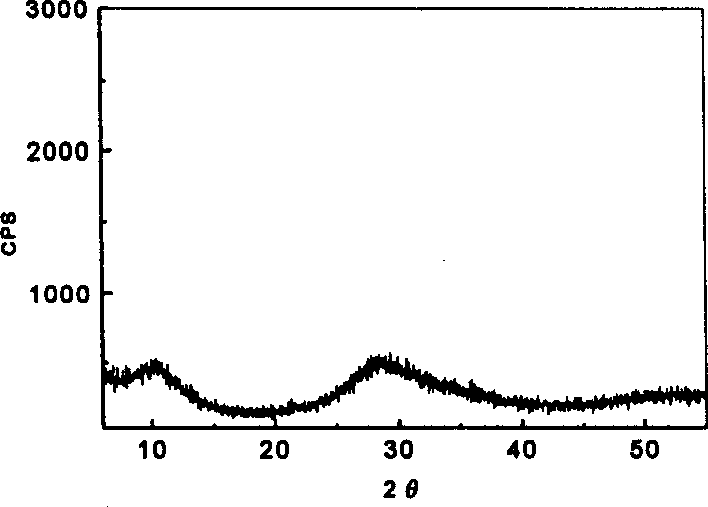

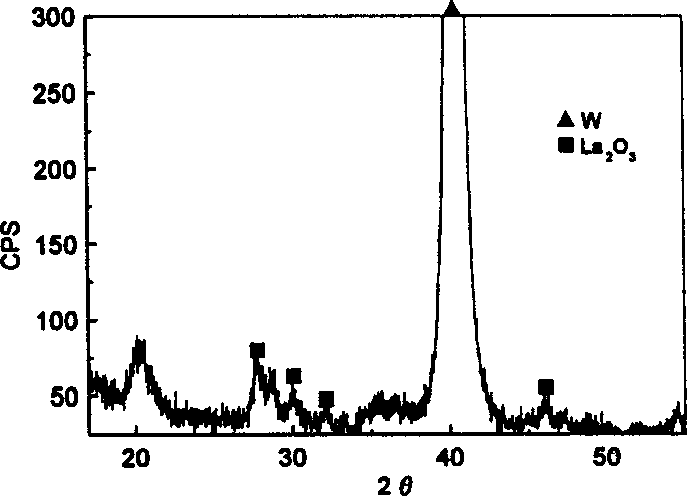

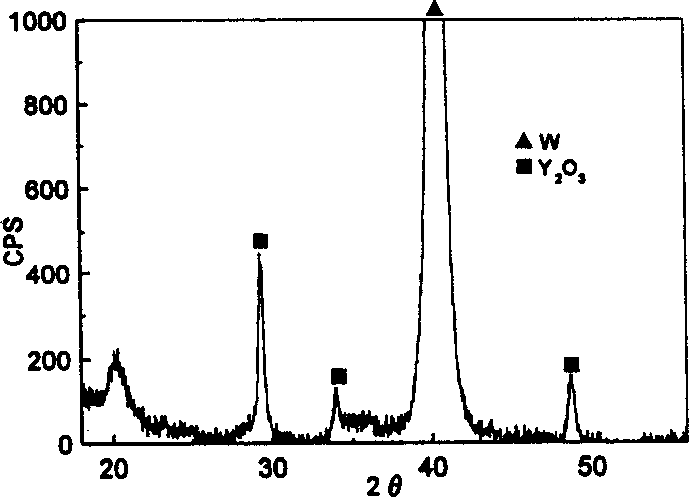

Image

Examples

example 1

[0024] Example 1: 155.66 grams of ammonium metatungstate white crystal powder is dissolved in 1000 milliliters of water, another 1.2910 grams of cerous nitrate white crystal powder is dissolved in 100 milliliters of water, after the two solutions are clarified, the two are mixed (where CeO 2 accounted for W-CeO 2 The weight percentage of mixed powder is 0.5%), pending clarification. Using a nitrogen spray gun with a gun pressure of 5 atm, disperse the clear mixed solution in liquid nitrogen. Then put the frozen material frozen in liquid nitrogen into the FTDDura-stop MP type freeze dryer of FTS company for vacuum drying. ℃; the working pressure within 2700-3900 minutes is 150 mTorr and the temperature is -12 °C; the working pressure within 3900-4700 minutes is 80 mTorr and the temperature is 0 °C; the working pressure within 4700-4900 minutes The temperature is 0 millitorr and the temperature is 15°C; the freeze-dried mixed powder is subjected to secondary reduction, the dop...

example 2

[0025] Example 2: 153.00 grams of ammonium metatungstate white crystal powder is dissolved in 1000 milliliters of water, another 5.6802 grams of cerous nitrate white crystal powder is dissolved in 100 milliliters of water, after the two solutions are clarified, the two are mixed (where CeO 2 accounted for W-CeO 2 The weight percent of mixed powder is 2.2%), pending clarification. Using a nitrogen spray gun with a gun pressure of 4 atm, disperse the clear mixed solution in liquid nitrogen. Then put the frozen material frozen in liquid nitrogen into the FTDDura-stop MP type freeze dryer of FTS company for vacuum drying. ℃; the working pressure within 2700-3900 minutes is 170 mTorr and the temperature is -12 °C; the working pressure within 3900-4700 minutes is 80 mTorr and the temperature is -3 °C; the working time within 4700-4900 minutes The pressure was 10 millitorr and the temperature was 25°C. The freeze-dried mixed powder is subjected to secondary reduction, the doped ce...

example 3

[0026] Example 3: 140.80 grams of ammonium metatungstate white crystal powder is dissolved in 1000 milliliters of water, another 25.8191 grams of cerous nitrate white crystal powder is dissolved in 100 milliliters of water, after two kinds of solutions are clarified, the two are mixed (wherein CeO 2 accounted for W-CeO 2 The weight ratio of mixed powder is 10.0%), pending clarification. Using a nitrogen spray gun with a gun pressure of 2 atm, disperse the clear mixed solution in liquid nitrogen. Then put the frozen material frozen in liquid nitrogen into the FTDDura-stop MP type freeze dryer of FTS company for vacuum drying. ℃; the working pressure within 2700~3900 minutes is 160 mTorr and the temperature is -10 °C; the working pressure within 3900~4700 minutes is 100 mTorr and the temperature is -1 °C; the working time within 4700~4900 minutes The pressure was 5 millitorr and the temperature was 20°C. The freeze-dried mixed powder is subjected to secondary reduction, the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com