Low-cost denitration catalyst and preparation process thereof

A denitration catalyst and manufacturing process technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of limited profit space, high catalyst price, and manufacturing cost constraints and other problems, to achieve the effect of improving denitration performance, increasing specific surface area, and improving wear resistance strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

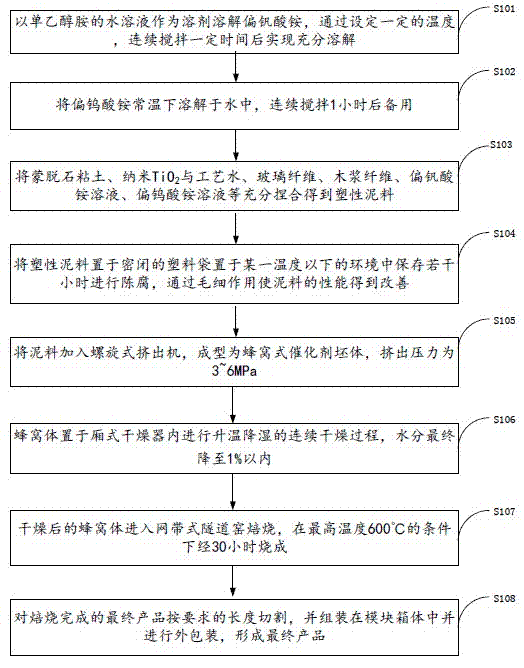

Method used

Image

Examples

specific Embodiment 1

[0028] Nano-TiO 2 Powder: 75%

[0029] Montmorillonite: 10%

[0030] Ammonium metatungstate: 6%

[0031] Ammonium metavanadate: 1%

[0032] Chopped glass fiber: 5%

[0033] Hardwood pulp fiber: 2%

[0034] Carboxymethylcellulose: 1.8%

[0035] Polyethylene oxide: 2%

[0036] Stearic acid: 1%

specific Embodiment 2

[0038] Nano-TiO 2 Powder: 70%

[0039] Montmorillonite: 15%

[0040] Ammonium metatungstate: 6%

[0041] Ammonium metavanadate: 1%

[0042] Chopped Glass Fiber: 4%

[0043] Hardwood pulp fiber: 2%

[0044] Carboxymethylcellulose: 1.5%

[0045] Polyethylene oxide: 1.6%

[0046] Stearic acid: 1%

specific Embodiment 3

[0048] Nano-TiO 2 Powder: 65%

[0049] Montmorillonite: 20%

[0050] Ammonium metatungstate: 6%

[0051] Ammonium metavanadate: 1%

[0052] Chopped Glass Fiber: 4.5%

[0053] Hardwood pulp fiber: 2%

[0054] Carboxymethylcellulose: 1.2%

[0055] Polyethylene oxide: 1.3%

[0056] Stearic acid: 1.2%

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com