Preparation method of nano tungsten carbide

A technology of nanometer tungsten carbide and tungsten powder is applied in the field of nanocrystalline cemented carbide materials and preparation, which can solve the problems of accelerating the volatilization of tungsten oxide and obtaining nanometer tungsten carbide powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

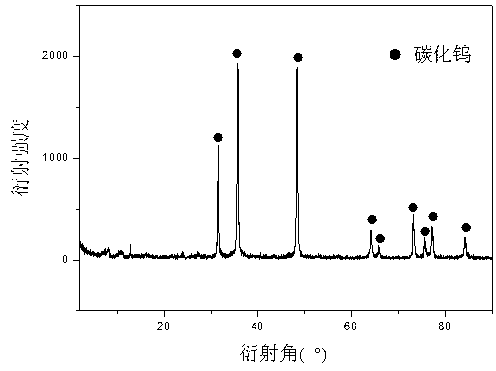

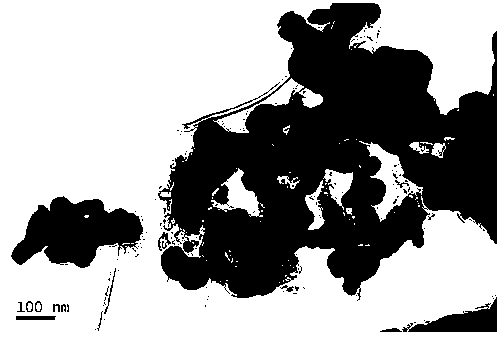

[0017] Weigh 180g of ammonium metatungstate, 20g of anhydrous glucose, and 1.5g of chromium nitrate, and dissolve them in deionized water at 80°C. After the raw materials are fully mixed, the precursors required for reduction are prepared by spray drying. The precursor powder was put into a tube-type atmosphere furnace, and hydrogen gas was introduced for reduction. The reduction temperature was 780°C, the heating rate was 10°C / min, and the time was 2h. After the reduction, the tungsten powder is annealed at a high temperature in a hydrogen atmosphere, the annealing temperature is 1000°C, and the annealing time is 3h. The tungsten powder after high temperature annealing is carbonized, the carbon ratio is 6.21wt.%, mixed evenly in the coulter batcher, and then carbonized in the tube atmosphere furnace, the carbonization condition is hydrogen atmosphere protection, and the carbonization temperature is 1100 ℃, the carbonization time is 4h, and after the carbonization is completed...

Embodiment 2

[0019] Weigh 180g of ammonium metatungstate, 20g of anhydrous glucose, and 1.5g of chromium nitrate, and dissolve them in deionized water at 80 °C. After the raw materials are fully mixed, the precursors required for reduction are prepared by spray drying. The precursor powder was put into a tube-type atmosphere furnace, and hydrogen gas was introduced for reduction. The reduction temperature was 800 °C, the heating rate was 15 °C / min, and the time was 3 h. After the reduction, the tungsten powder is annealed at a high temperature in a hydrogen atmosphere, the annealing temperature is 1100°C, and the annealing time is 2.5h. The tungsten powder after high temperature annealing is carbonized, the carbon ratio is 6.21wt.%, and then carbonized in a tubular atmosphere furnace, the carbonization condition is hydrogen atmosphere protection, the carbonization temperature is 1200 °C, the carbonization time is 2h, and the carbonization is completed Finally, before the powder comes out o...

Embodiment 3

[0021] Weigh 170g of ammonium metatungstate, 30g of anhydrous glucose, and 2.5g of chromium nitrate, and dissolve them in deionized water at 80°C. After the raw materials are fully mixed, the precursors required for reduction are prepared by spray drying. The precursor powder was put into a tube-type atmosphere furnace, and hydrogen gas was introduced for reduction. The reduction temperature was 780°C, the heating rate was 10°C / min, and the time was 2h. After the reduction, the tungsten powder is annealed at a high temperature in a hydrogen atmosphere, the annealing temperature is 1300°C, and the annealing time is 1h. The tungsten powder after high temperature annealing is carbonized, the carbon ratio is 6.21wt.%, and then carbonized in a tubular atmosphere furnace, the carbonization condition is hydrogen atmosphere protection, the carbonization temperature is 1300 ° C, the carbonization time is 3h, and the carbonization is completed Finally, before the powder comes out of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com