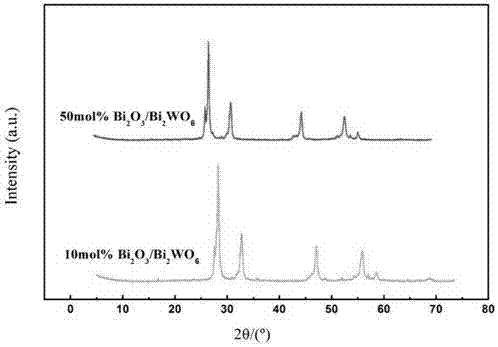

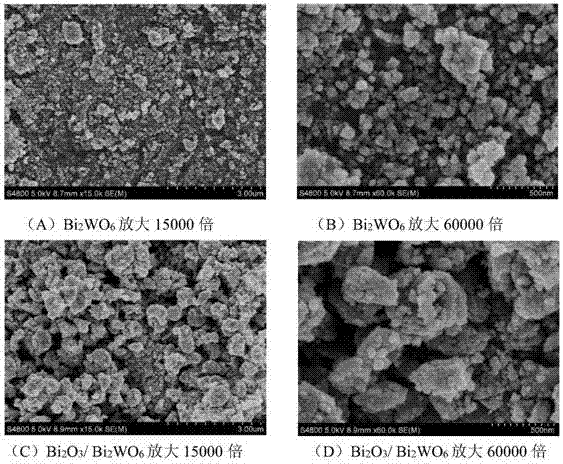

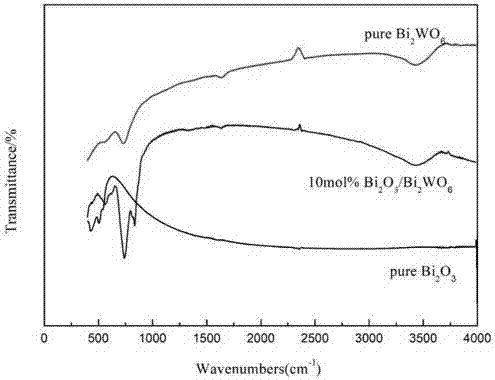

Bismuth trioxide-bismuth tungstate heterojunction photocatalyst and preparation method thereof

A technology of bismuth trioxide and photocatalyst, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, chemical instrument and method, etc., to achieve high photocatalytic efficiency, high utilization rate, good photocatalytic activity and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The first step: take 0.00025mol (0.7391g) (NH 4 ) 10 W12 o 41 ·5H 2 O was dissolved in 18ml of ethylene glycol under the condition of magnetic stirring, which was recorded as A solution.

[0036] The second part: take 0.0066mol (3.2015g) Bi (NO 3 ) 3 ·5H 2 O was dissolved in 18ml of ethylene glycol with the assistance of ultrasound, which was recorded as solution B.

[0037] The third part: Under the condition of magnetic stirring, slowly add solution A to solution B, then add 36ml of ethanol, continue to stir for 10 minutes until the mixture is uniform, and record it as solution C.

[0038] Step 4: Move the C solution into a hydrothermal reaction kettle, and place it in a blast drying oven at a constant temperature of 170°C for 6 hours

[0039] Step 5: Take out the reactant, wash it several times with absolute ethanol, and dry it at 60°C for 6 hours

[0040] Step 6: Place the dried product in a muffle furnace at 400°C to calcinate it into powder, take it out af...

Embodiment 2

[0047] The first step: take 0.00025mol (0.7391g) (NH 4 ) 10 W 12 o 41 ·5H 2 O was dissolved in 18ml of ethylene glycol under the condition of magnetic stirring, which was recorded as A solution.

[0048] The second part: Take 0.0072mol (3.4925g) Bi(NO 3 ) 3 ·5H 2 O was dissolved in 18ml of ethylene glycol with the assistance of ultrasound, which was recorded as solution B.

[0049] The third part: Under the condition of magnetic stirring, slowly add solution A to solution B, then add 36ml of ethanol, continue to stir for 10 minutes until the mixture is uniform, and record it as solution C.

[0050] Step 4: Move the C solution into a hydrothermal reaction kettle, and place it in a blast drying oven at a constant temperature of 170°C for 6 hours

[0051] Step 5: Take out the reactant, wash it several times with absolute ethanol, and dry it at 60°C for 6 hours

[0052] Step 6: Place the dried product in a muffle furnace at 400°C to calcinate it into powder, take it out a...

Embodiment 3

[0059] The first step: take 0.00025mol (0.7391g) (NH 4 ) 10 W 12 o 41 ·5H 2 O was dissolved in 18ml of ethylene glycol under the condition of magnetic stirring, which was recorded as A solution.

[0060] The second part: Take 0.0078mol (3.7835g) Bi(NO 3 ) 3 ·5H 2 O was dissolved in 18ml of ethylene glycol with the assistance of ultrasound, which was recorded as solution B.

[0061]The third part: Under the condition of magnetic stirring, slowly add solution A to solution B, then add 36ml of ethanol, continue to stir for 10 minutes until the mixture is uniform, and record it as solution C.

[0062] Step 4: Move the C solution into a hydrothermal reaction kettle, and place it in a blast drying oven at a constant temperature of 170°C for 6 hours

[0063] Step 5: Take out the reactant, wash it several times with absolute ethanol, and dry it at 60°C for 6 hours

[0064] Step 6: Place the dried product in a muffle furnace at 400°C to calcinate it into powder, take it out af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com