Method for preparing steady phase-A vanadium dioxide nanorod

A technology of vanadium dioxide and nanorods, which is applied in the field of preparation of phase A vanadium dioxide powder, can solve the problems of difficult synthesis, high synthesis temperature, and small filling ratio, and achieve good crystallinity, good ductility, and crystallinity. The effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

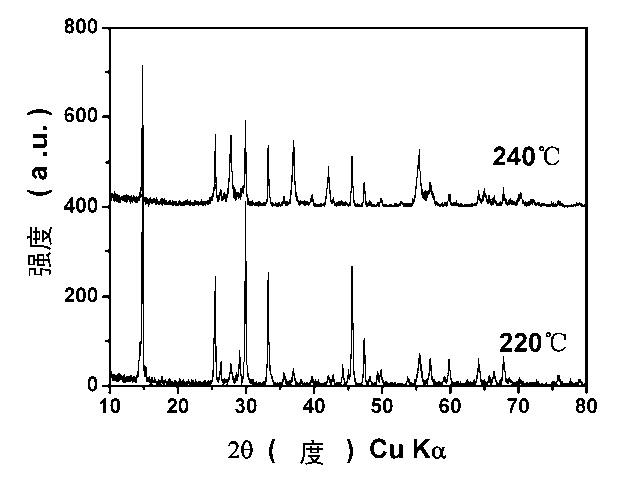

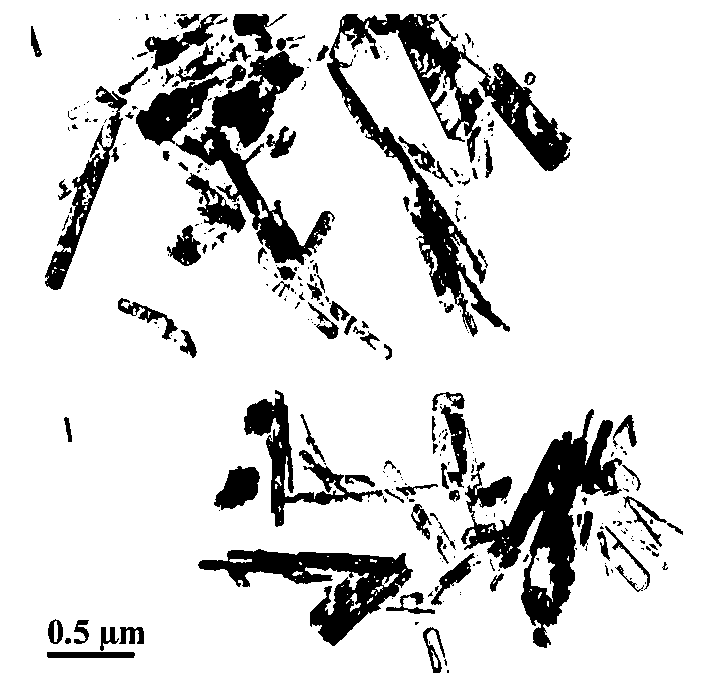

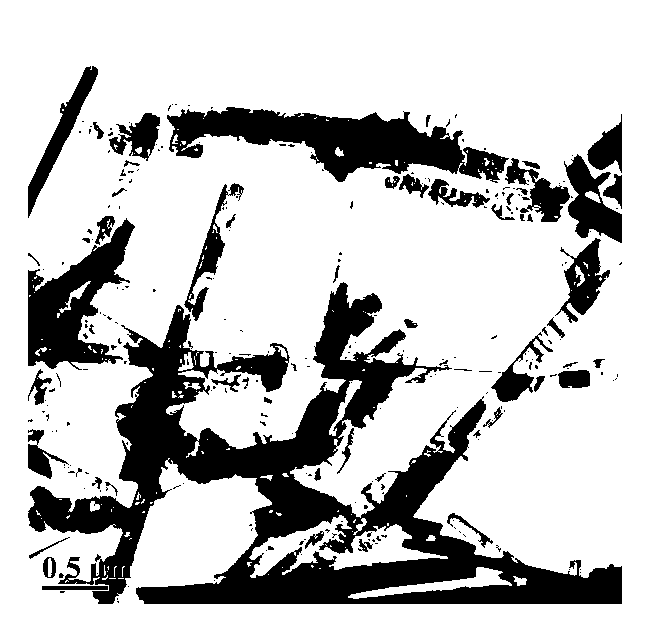

[0032] Disperse 3.64 g of vanadium pentoxide powder in 200 g of an aqueous solution of oxalic acid with a concentration of 0.1 M, and stir vigorously for 10 minutes to obtain an aqueous solution of vanadium ions with a molar concentration of 0.2 mol / L and a pH of 2.1. The above solution was added to a 250ml hydrothermal kettle, the filling ratio was 80%, the temperature was raised to 200°C, the temperature was maintained for 24 hours, synthesized through a hydrothermal reaction, slowly cooled to room temperature, centrifuged, and dried in an oven at 70°C for 24 hours to obtain The A-phase vanadium dioxide nanorods were 2.97 g, and the yield was 99%. like figure 1 The XRD spectrum shows that its crystal phase is pure A phase, such as figure 2 As shown in the TEM photo, the obtained vanadium dioxide powder is rod-shaped, and each vanadium dioxide rod is a single crystal and has a certain length and thickness. After testing, the obtained A-phase vanadium dioxide nanorods have...

Embodiment 2

[0034] 4.5 g of oxalic acid (2M) was added to 125 ml of an aqueous solution of vanadium oxychloride with a concentration of 0.005 mol / L, and vigorously stirred for 10 minutes to obtain an aqueous solution of vanadium ions with a molar concentration of 0.005 mol / L and a pH of 1.5. The above solution was added to a 250ml hydrothermal kettle, the filling ratio was 50%, the temperature was raised to 219°C, the temperature was maintained for 0 hours, synthesized through a hydrothermal reaction, then slowly cooled to room temperature, centrifuged, and dried in an oven at 70°C for 24 hours. 0.8 g of A-phase vanadium dioxide nanorods were obtained with a yield of 98%. After testing, the obtained A-phase vanadium dioxide nanorods have a diameter of 500 nm and a length of 1-6 μm. The aspect ratio is: 1:1~12:1.

Embodiment 3

[0036] 150 ml of an aqueous solution of vanadyl oxalate with a molar concentration of 0.1 mol / L was prepared, stirred vigorously for 10 minutes, and the pH was 2.6. The above solution was added to a 250ml hydrothermal kettle, the filling ratio was 60%, the temperature was raised to 200°C, the temperature was maintained for 1 hour, synthesized by hydrothermal reaction, then slowly cooled to room temperature, centrifuged, and dried in an oven at 70°C for 24 hours , 2.2 g of A-phase vanadium dioxide nanorods were obtained with a yield of 98%. After testing, the obtained A-phase vanadium dioxide nanorods have a diameter of 1 μm, a length of 30 to 50 μm, and an aspect ratio of 30:1 to 50:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com