Rodlike aragonite calcium carbonate preparation method

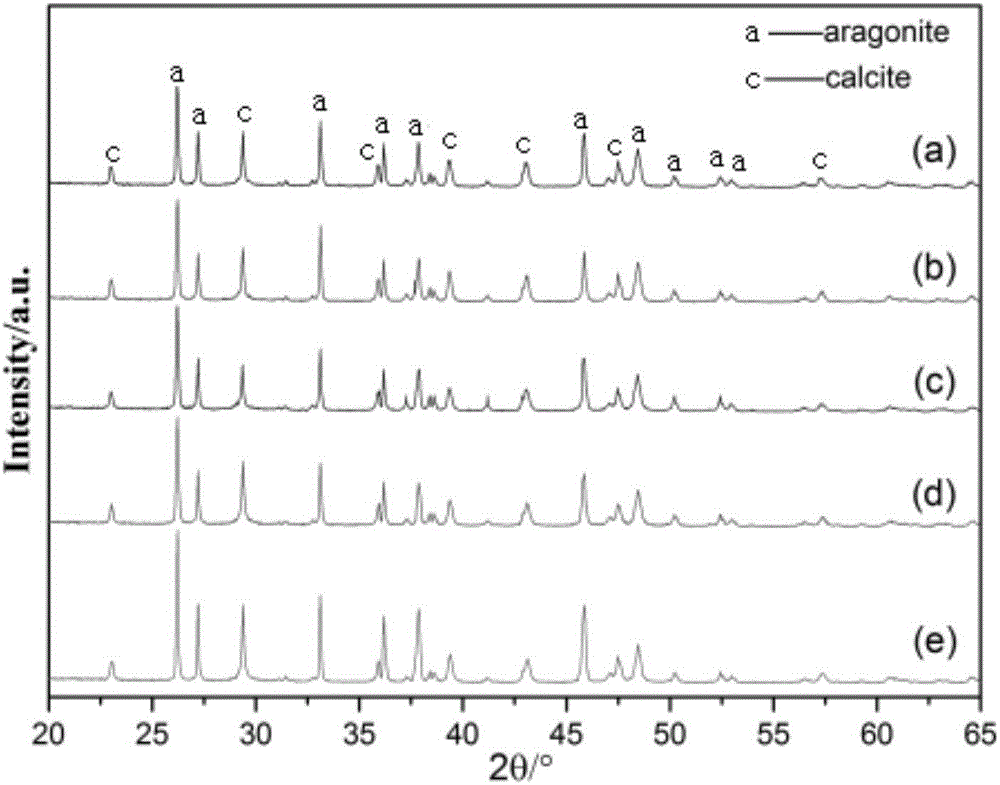

An aragonite-type, calcium carbonate technology, applied in calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problems of high cost, low production efficiency, high energy consumption, etc. High temperature resistant elastic modulus, high production efficiency and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

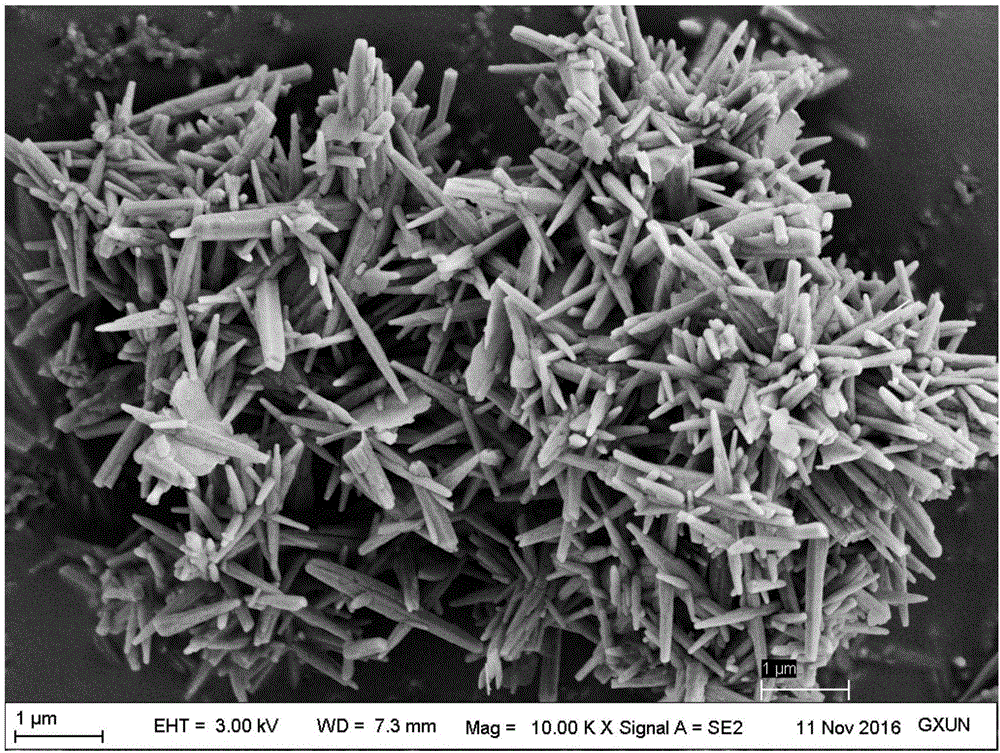

Embodiment 1

[0041] A preparation method of rod-shaped aragonite calcium carbonate, comprising the following steps:

[0042] (1) Crushing the limestone, calcining at a temperature of 900°C for 6 hours, then digesting the calcined limestone with a gray-to-water mass ratio of 1:4, and controlling the water temperature to 28°C to obtain lime slurry;

[0043] (2) Pass the lime slurry obtained in step (1) through an 80-mesh sieve, filter to remove slag, add water to adjust the solid content of the lime slurry to 10%, and obtain refined lime slurry for subsequent use;

[0044] (3) Control the temperature of the refined lime slurry at 55~60°C, add calcium hydroxide in the lime slurry with a mass of 0.3% glutaric acid, 0.5% barium sulfate and 0.1% polyethylene glycol as crystal form control agents, and then transport Into the carbonization tower, adjust the stirring rate to 400r / min, pass through the kiln gas with a carbon dioxide concentration of 20% for carbonation reaction until the pH is 8.0, ...

Embodiment 2

[0048] A preparation method of rod-shaped aragonite calcium carbonate, comprising the following steps:

[0049] (1) Crushing the limestone, calcining at a temperature of 1250°C for 3 hours, then digesting the calcined limestone at a gray-to-water mass ratio of 1:6.5, controlling the water temperature to 28°C to obtain lime slurry;

[0050] (2) Pass the lime slurry obtained in step (1) through a 100-mesh sieve, filter to remove slag, add water to adjust the solid content of the lime slurry to 12%, and obtain refined lime slurry for subsequent use;

[0051](3) Control the temperature of the refined lime slurry to 30-35°C, add 0.4% oxalic acid, 0.6% zinc chloride and 0.2% sodium lauryl sulfate as crystal form control agents to the calcium hydroxide in the lime slurry, and then Transport it to the carbonization tower, adjust the stirring rate to 350r / min, pass through the kiln gas with a carbon dioxide concentration of 25% for carbonation reaction until the pH is 8.0, control the ...

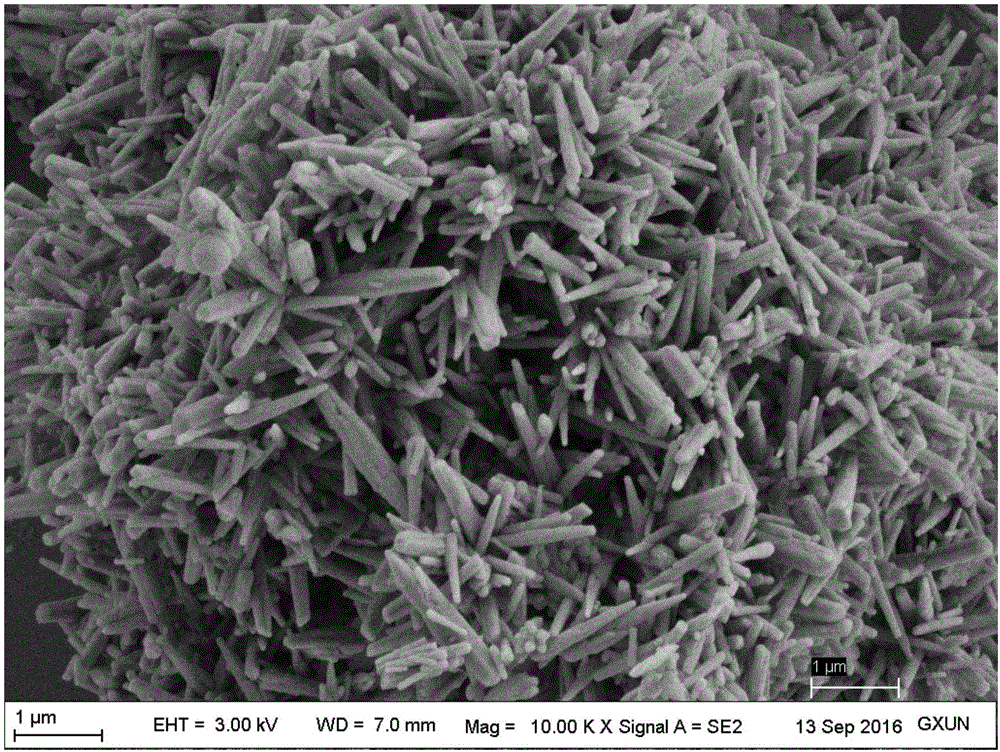

Embodiment 3

[0055] A preparation method of rod-shaped aragonite calcium carbonate, comprising the following steps:

[0056] (1) Crushing the limestone, calcining at a temperature of 1200°C for 4 hours, then digesting the calcined limestone at a gray-to-water mass ratio of 1:3, and controlling the water temperature to 30°C to obtain lime slurry;

[0057] (2) Pass the lime slurry obtained in step (1) through an 80-mesh sieve, filter to remove slag, add water to adjust the solid content of the lime slurry to 7%, and obtain refined lime slurry for subsequent use;

[0058] (3) Control the temperature of the refined lime slurry at 30-35°C, add calcium hydroxide in the lime slurry with 0.5% succinic acid, 0.8% calcium nitrate and 0.1% sodium lauryl sulfate as the crystal form control agent, and then Transport to the carbonization tower, adjust the stirring rate to 300r / min, feed the kiln gas with a carbon dioxide concentration of 15% for carbonation reaction until the pH is 8.0, control the flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com