Monodispersed vaterite type calcium carbonate microsphere and preparation method thereof

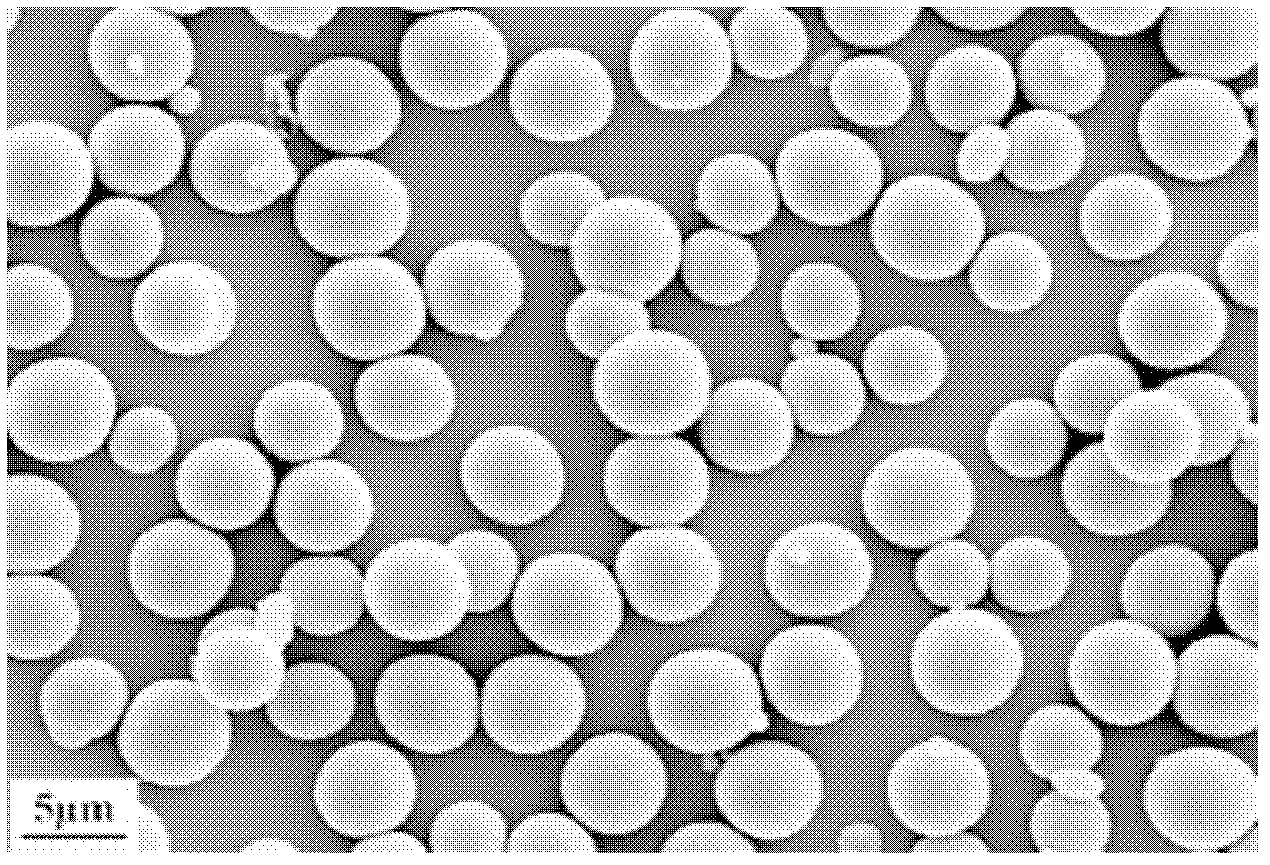

A technology of calcium carbonate and vaterite, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of wide particle size distribution and poor crystal stability, and achieve high density of surface functional groups, low cost and short aging time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

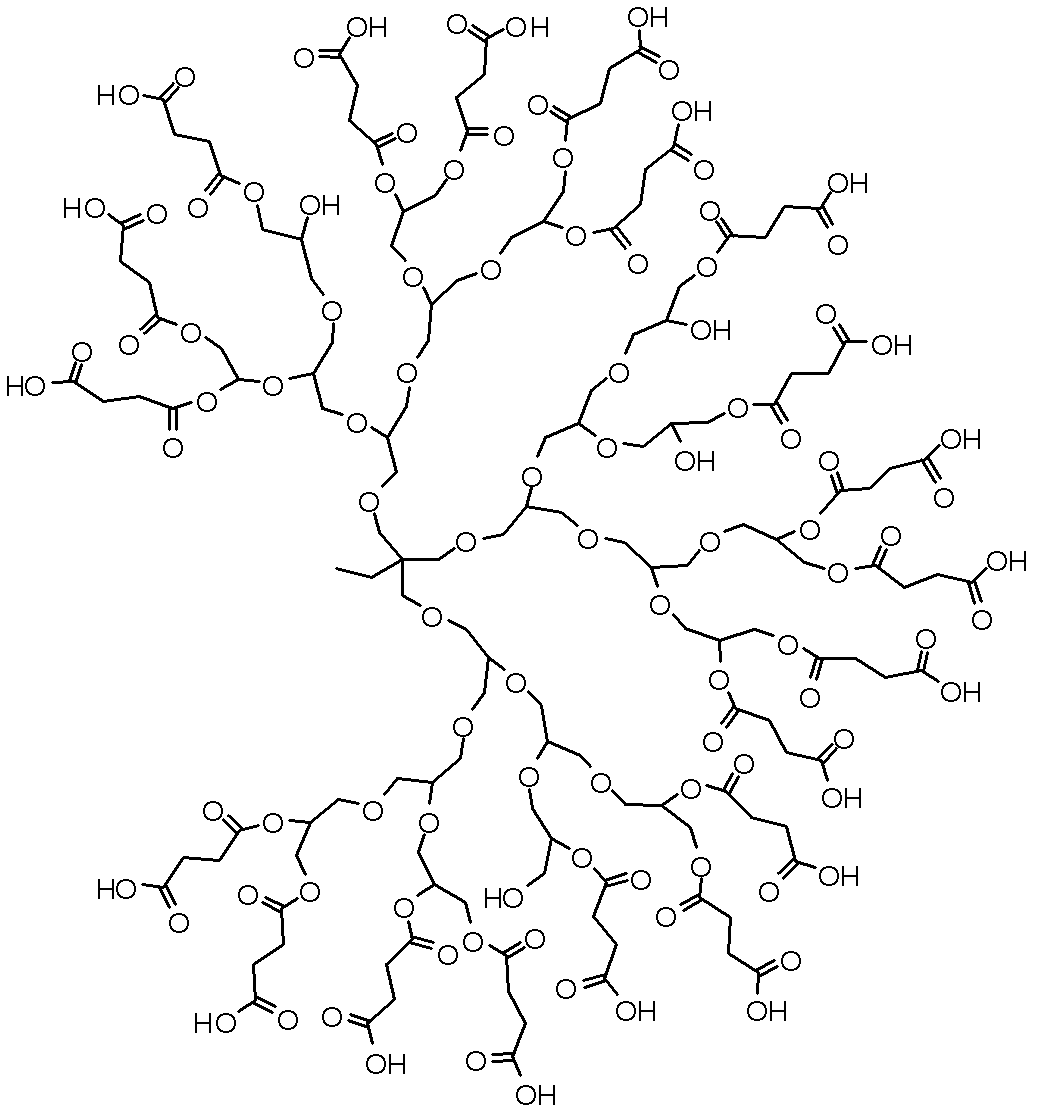

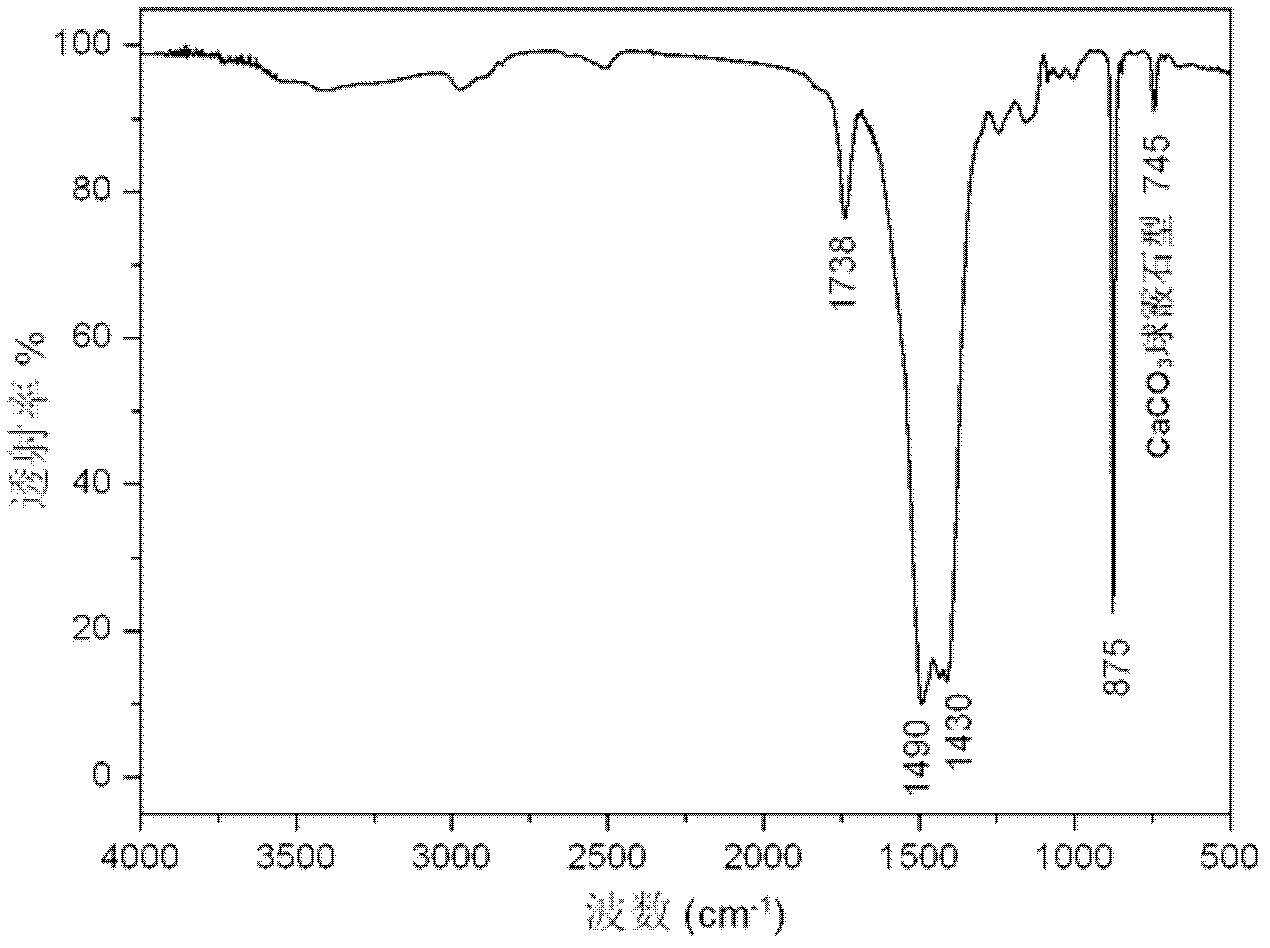

[0048] (1) Preparation of carboxyl-functionalized hyperbranched polyglycidyl ether: weigh 1.48mmol in a dry three-necked bottle, and the degree of polymerization is 21 hydroxyl hyperbranched polyglycidyl ether, dissolve with 30mL dimethylacetamide, Add 35.5mmol of succinic anhydride and 0.01g of 4-dimethylaminopyridine, heat to 100°C under nitrogen protection and stir for 6h; cool to room temperature, add 15mL of methanol, and stir for 12h; Drop into the mixed solvent of dichloromethane / diethyl ether (volume ratio is 1: 2) to precipitate the crude product; then transfer to a dialysis membrane with a molecular weight cut-off of 500 and dialyze in deionized water for 48 hours to remove small molecules and ionic impurities; Concentrate and dry to obtain carboxyl functionalized hyperbranched polyglycidyl ether (molecular structure schematic diagram as figure 1 ), productive rate 89%; Characterization result is as follows: 1 H NMR (Acetone-d 6 , 300MHz): (ppm) 0.78 (m, -CH 2 C ...

Embodiment 2

[0054] (1) The preparation method of the carboxyl functionalized hyperbranched polyglycidyl ether in this example is the same as in Example 1;

[0055] (2) Preparation of carboxyl-functionalized hyperbranched polyglycidyl ether aqueous solution (concentration: 150 mg / L): Add 75 mg of carboxyl-functionalized hyperbranched polyglycidyl ether solid into 500 mL of deionized water, stir until completely dissolved, and use hydrogen oxidation Sodium or hydrochloric acid adjustment solution pH value is 10;

[0056] (3) Preparation of calcium chloride aqueous solution (concentration is 150mmol / L): add 8.33g of anhydrous calcium chloride solid into 500mL of deionized water, stir until completely dissolved, use sodium hydroxide or hydrochloric acid to adjust the pH value of the solution to 10;

[0057] (4) Preparation of sodium carbonate aqueous solution (concentration is 150mmol / L): add 7.95g sodium carbonate solid into 500mL deionized water, stir until completely dissolved, use sodium ...

Embodiment 3

[0060] (1) Preparation of carboxyl functionalized hyperbranched polyglycidyl ether: weigh 0.72mmol in a dry three-neck bottle, and the degree of polymerization is 45 hydroxyl hyperbranched polyglycidyl ether, dissolve with 40mL dimethylacetamide, Add 38.1 mmol of succinic anhydride and 0.02 g of 4-dimethylaminopyridine, heat to 100°C under nitrogen protection and stir for 6 h; cool to room temperature, add 15 mL of methanol, and stir for 12 h; the obtained reaction solution is firstly distilled off under reduced pressure to remove methanol; Then drop into the mixed solvent of dichloromethane / ether (volume ratio is 1: 2) to precipitate the crude product; then transfer to a dialysis membrane with a molecular weight cut-off of 500 and dialyze in deionized water for 48h to remove small molecules and ion impurities; finally Carboxyl functionalized hyperbranched polyglycidyl ether can be obtained after concentration and drying with a yield of 85%; the characterization results are as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com