Method for producing aripiprazole crystallite

An aripiprazole and microcrystal technology, which is applied in the field of preparation of aripiprazole microcrystals, can solve problems such as excessive crystal grain size, and achieve the effects of simple process, no equipment and small crystal grain size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

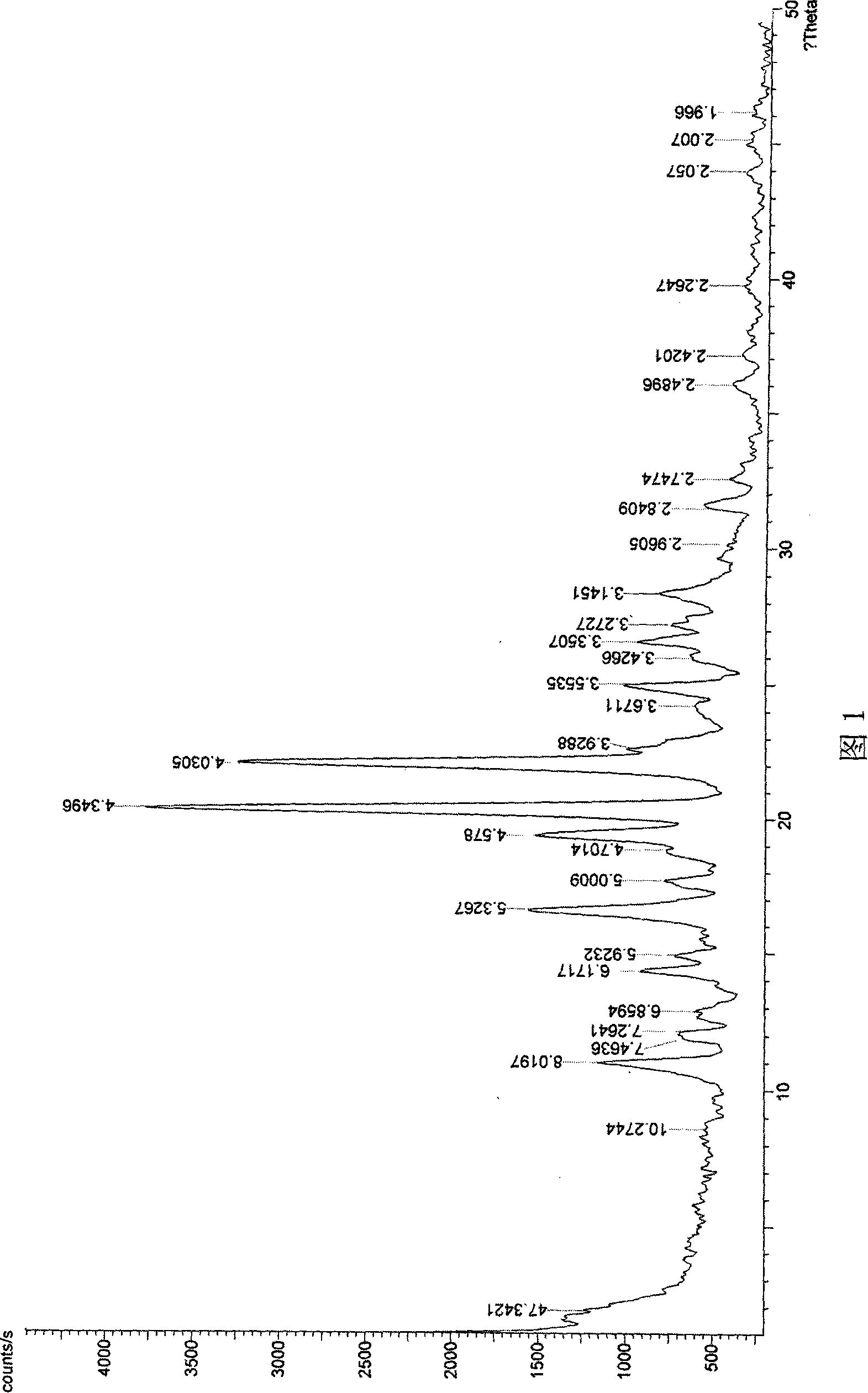

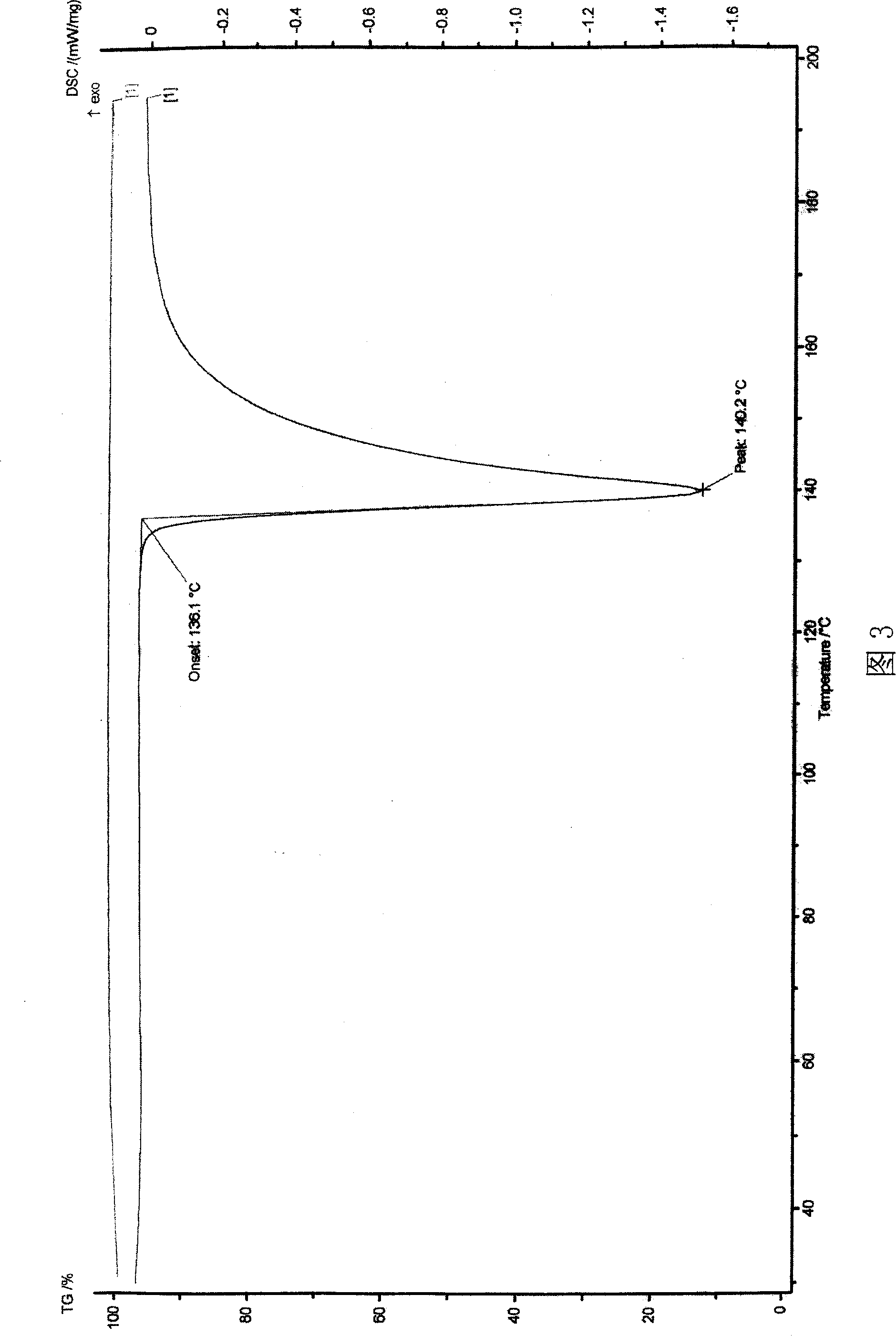

[0028] Add 20g of aripiprazole and 240ml of ethanol into a three-necked reaction flask with a reflux condenser, heat to reflux under stirring, stop heating after the aripiprazole is completely dissolved, adjust the line speed to 500 m / min, and add 1°C 37ml of low-temperature water, cooled rapidly with ice-water mixture for 30min, suction filtered, washed, the obtained crystals were placed in a desiccator at 80°C, and dried under reduced pressure for 10 hours to obtain 19.2g of powdery aripiprazole crystals, with a yield of 96%. mp: 138.5-139.4°C, measured its powder X-ray diffraction pattern, the results are shown in Figure 1. Determination of its differential calorimetry scan and thermogravimetric diagram, the results are shown in Figure 3

[0029] The mensuration of aripiprazole crystallite particle size: get the crystallization that present embodiment obtains in right amount, take water as dispersant, measure with Mastersizer 2000 laser particle size analyzer, volume averag...

Embodiment 2

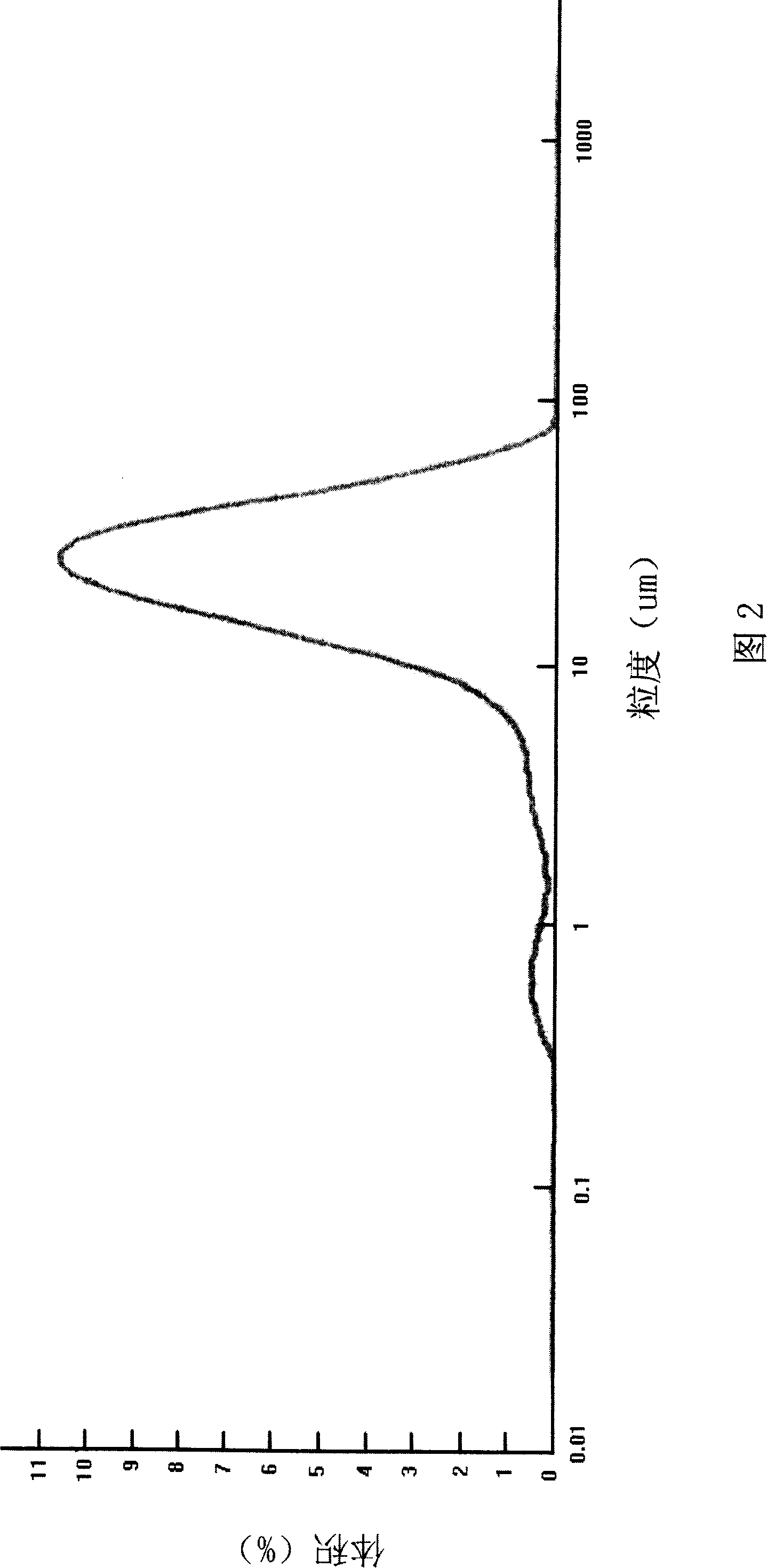

[0034] Add 20g of aripiprazole, 190ml of ethanol and 50ml of water into a three-necked reaction flask with a reflux condenser, heat to reflux under stirring, stop heating after the aripiprazole is completely dissolved, adjust the line speed to 500 m / min, and simultaneously Add 37ml of low-temperature water at 1°C, cool down rapidly with ice-water mixture for 30min, filter with suction, wash, and dry the obtained crystals in a desiccator at 90°C for 11 hours to obtain 19.4g of powdery aripiprazole crystals, yield 97%, mp: 138.4-139.1°C. Measure its particle diameter according to the method for embodiment 1,: volume average particle diameter volume average particle diameter 24.991um, d(0.9)=44.377, d(0.5)=22.868, d(0.1)=8.901, its particle size spectrum is shown in the figure 2.

[0035] The range of crystallite size is shown in Table 2.

[0036] Table 2 particle size and volume ratio

[0037] Granularity (um)

Embodiment 3

[0039] Add 20g of aripiprazole, 190ml of ethanol and 50ml of ethyl acetate into a three-necked reaction flask with a reflux condenser, heat to reflux under stirring, stop heating after the aripiprazole is completely dissolved, and adjust the line speed to 500 m / min At the same time, 37ml of low-temperature water at 1°C was added, and the temperature was rapidly cooled with ice-water mixture for 30 minutes, suction filtered, washed, and the obtained crystals were placed in an ebullating bed at 85°C, and boiled and dried for 1 hour to obtain powdered aripiprazole crystals 19.1, yield 95.5%, mp: 138.4-139.4°C,. Measure its particle diameter by the method for embodiment 1: volume average particle diameter 25.827um, d(0.9)=45.128, d(0.5)=23.156, d(0.1)=9.253

[0040] The range of crystallite size is shown in Table 3.

[0041] Table 3 particle size and volume ratio

[0042] Granularity (um)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com